Data Analytics with MackSmaTec.

Understanding Data, Unlocking Potential.

Use your production data as a strategic lever: with our data analytics solutions, you can recognize patterns, identify deviations at an early stage and make informed decisions – for greater efficiency, quality and plant availability.

-

- /

Our Solutions

at a Glance

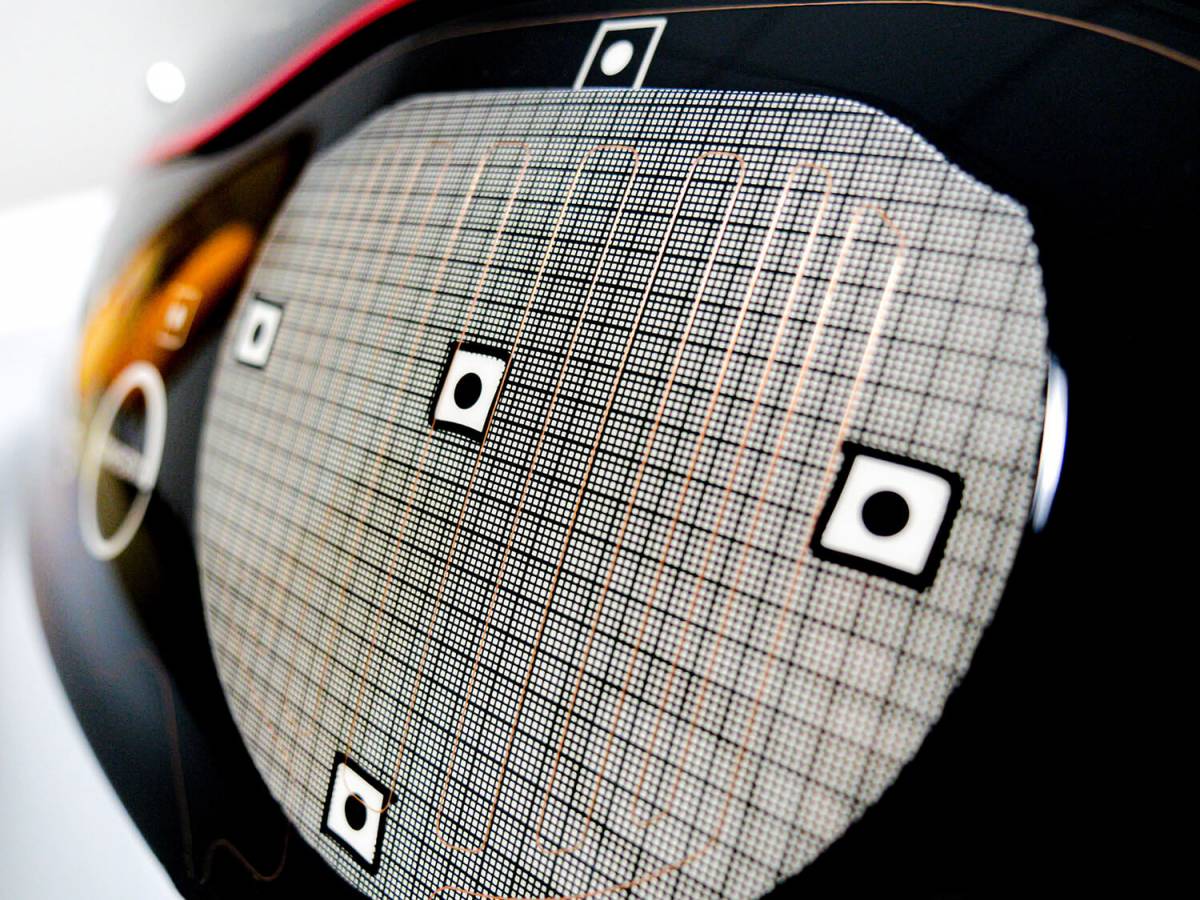

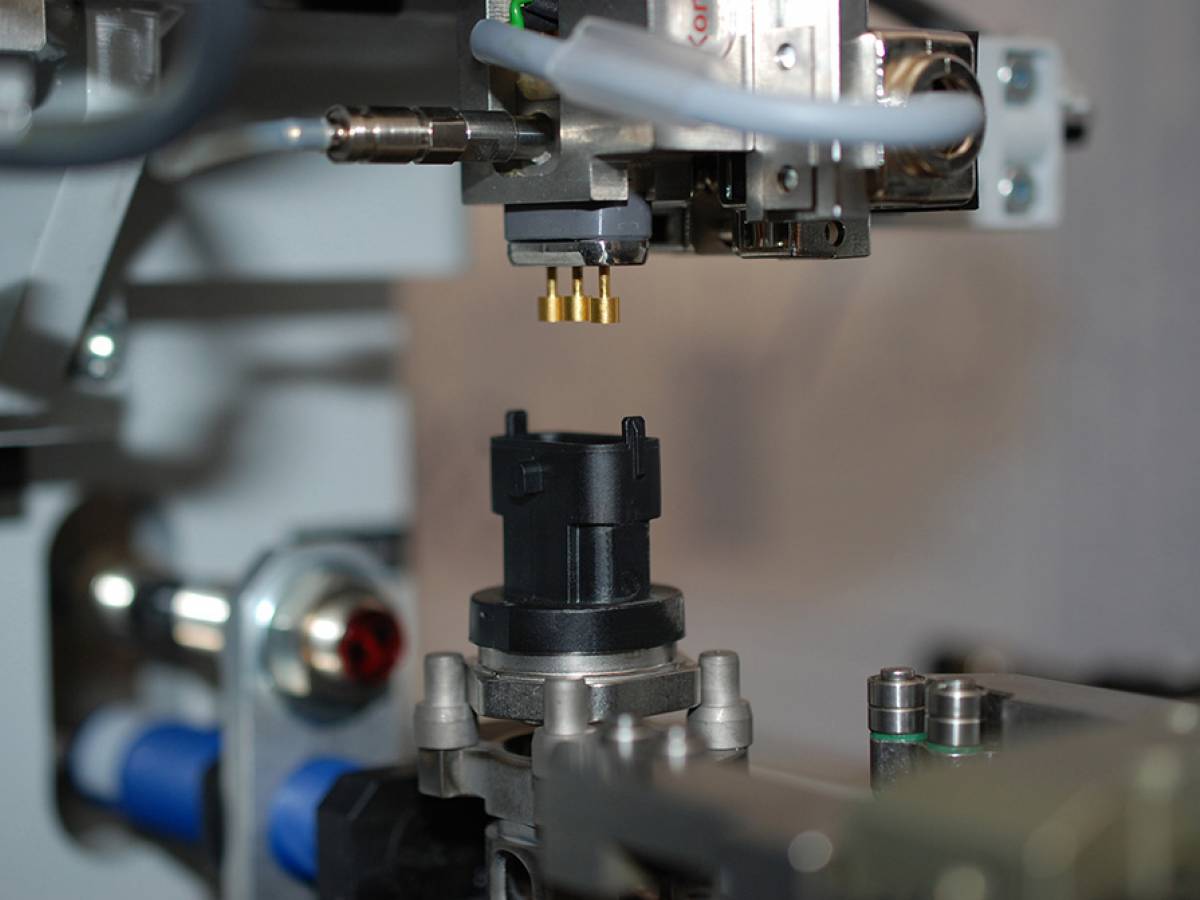

Process Analysis

More Insight. More Control.

We make data relating to machine performance, material flow and quality indicators usable. Our process analysis provides you with in-depth insights into the status and utilization of your systems and detects quality deviations in real time. It supports data-based optimization and is tailored to your production environment.

Your added value:

In-depth analysis: Comprehensive understanding of your production processes

Early warning system for quality: quality deviations are detected and rectified immediately

Better use of resources: Optimum utilization of your machines and production capacities

Well-founded decisions: Data-based optimizations enable targeted measures

Energy Management Aystems

Managing Energy Consumption. Promote Sustainability.

Analyze the energy consumption of your machines and systems precisely and continuously and use the knowledge gained to avoid peak loads, uncover inefficiencies and implement targeted energy-saving measures in order to control costs and achieve your sustainability goals. MackSmaTec systems can be easily integrated into your existing infrastructure.

Benefit from:

Potential energy savings: Identification and implementation of targeted measures to reduce costs

Transparent energy flows: Clear presentation of consumption - for greater control and comparability

ISO 50001 compliance: standard-compliant documentation and preparation for audits

Sustainable production: Reduced carbon footprint through efficient energy use

Your Benefits with MackSmaTec

Data Analytics

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.