PERFLEX®

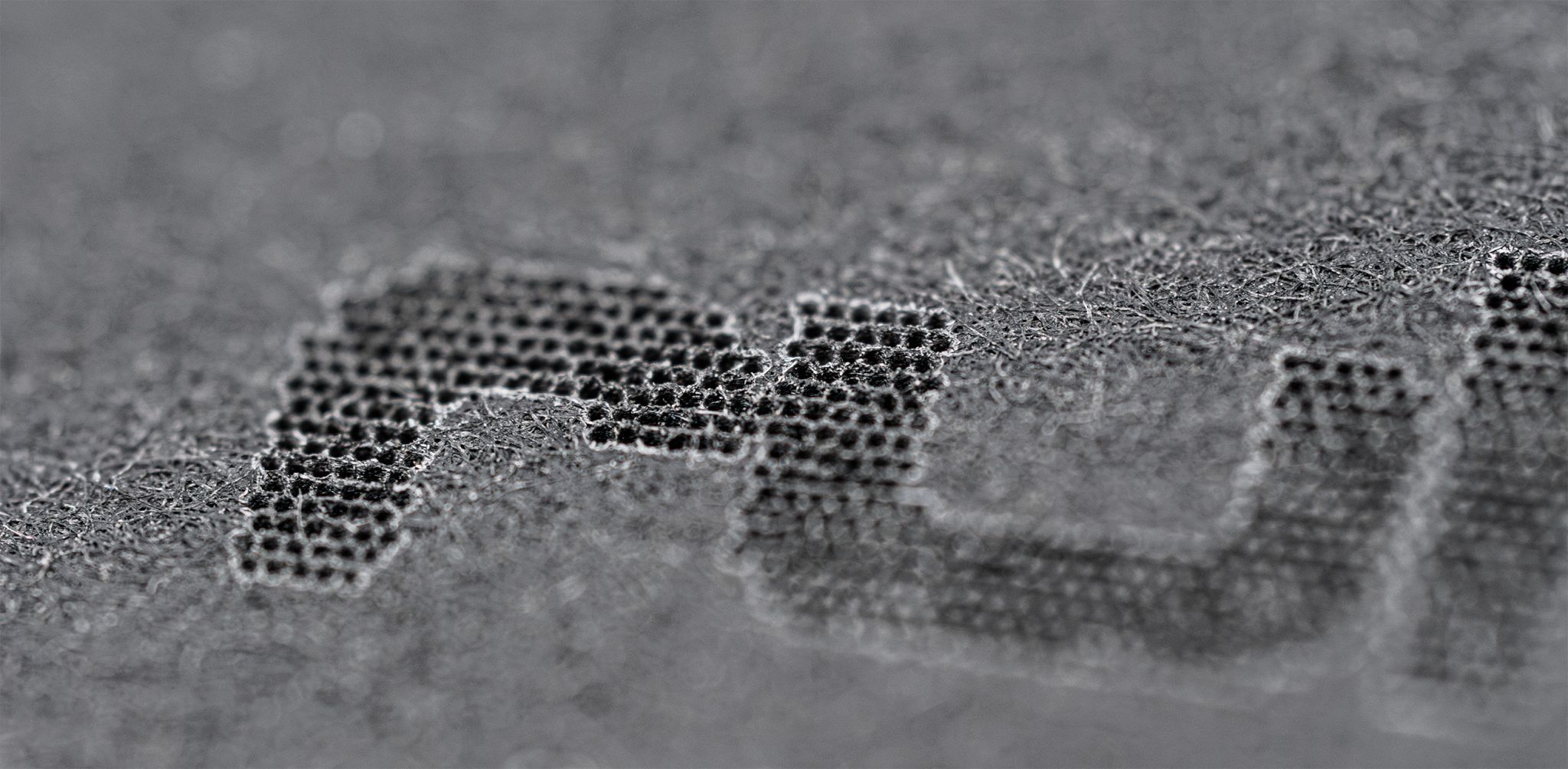

Laser perforation for secure documents.

Our patented laser perforation solution enables precise, non-contact processing of security documents and a wide variety of materials - for permanent marking

for permanent marking, maximum counterfeit protection and functional perforations.

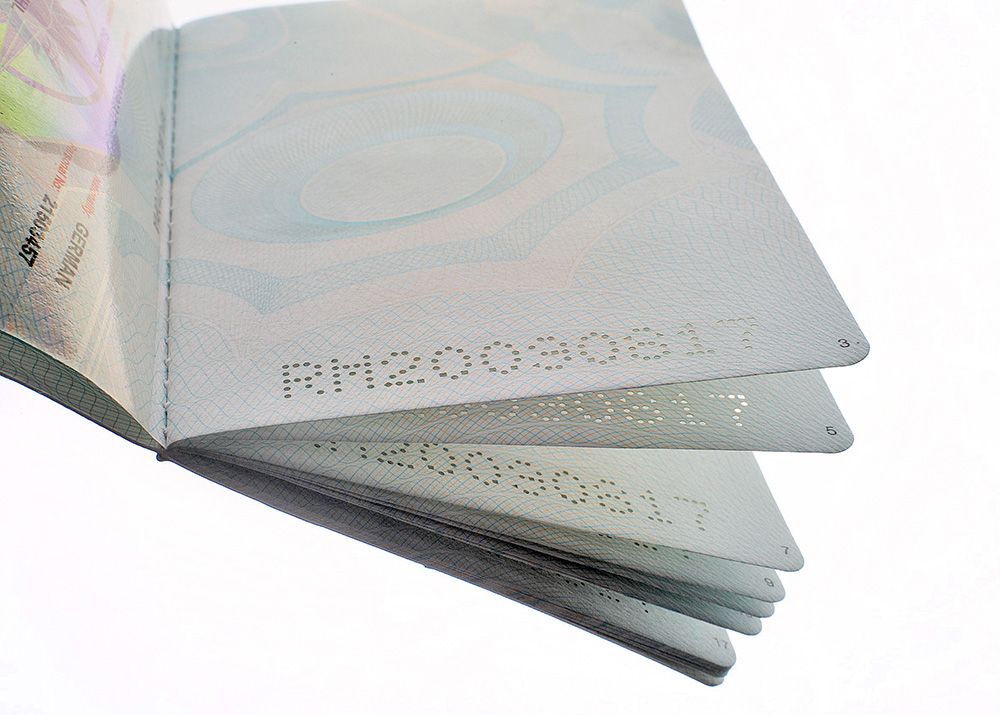

Laser perforation for high-security documents

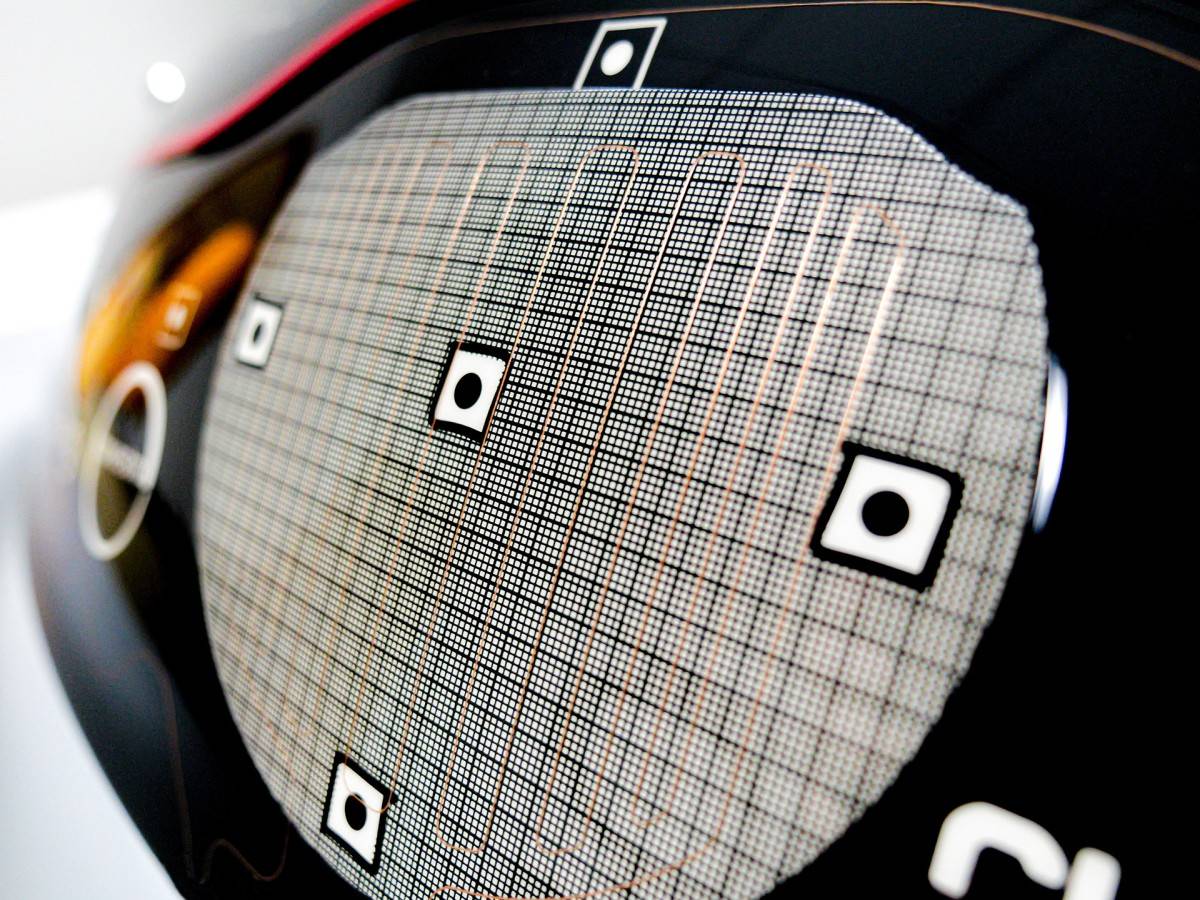

Our laser perforation technology is used worldwide for the forgery-proof personalization of passports, ePassports and ID documents. The patented solution enables, among other things

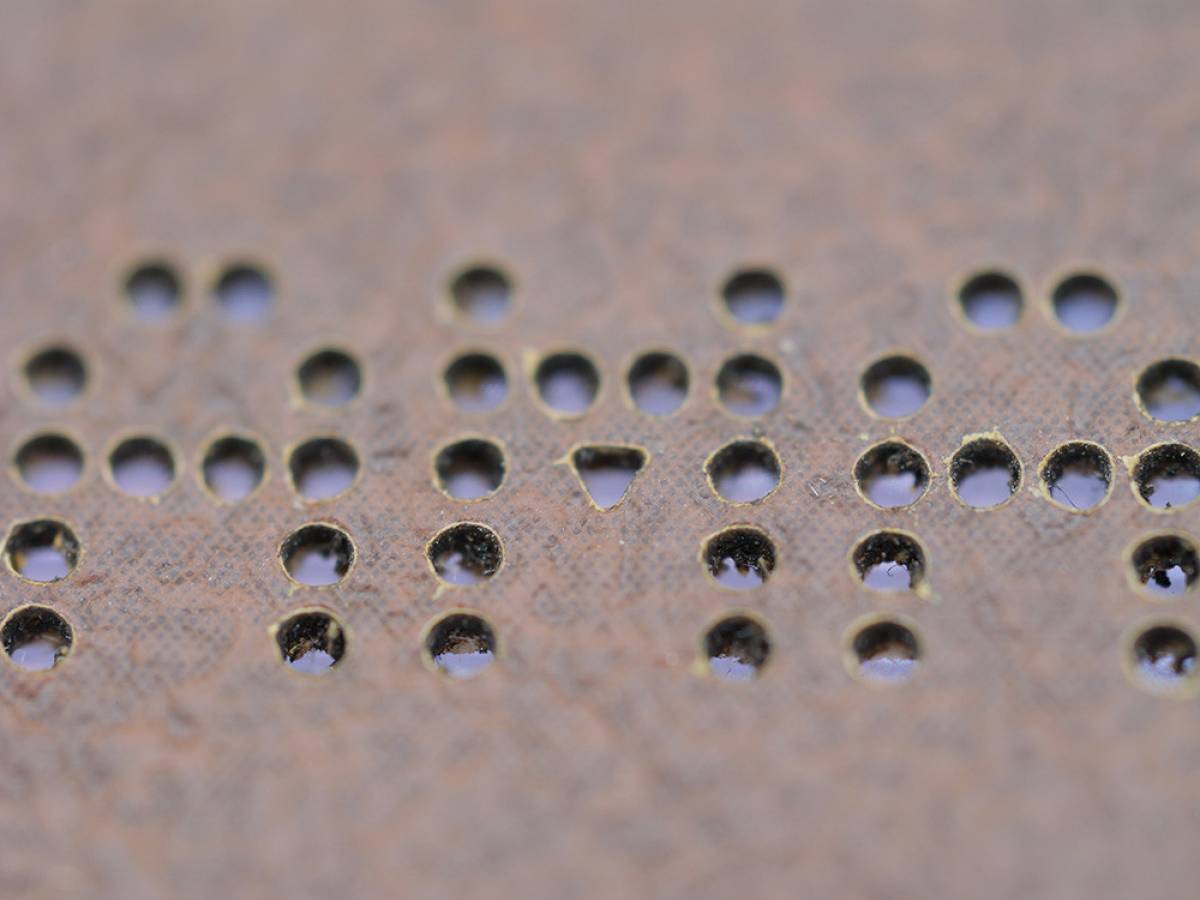

Conical microperforations for the display of passport numbers

Variable character shapes (e.g. triangles, diamonds, trapezoids)

Perforation through several pages (paper and polycarbonate) up to the back cover of the book

Integrated quality assurance with high cycle times

These features make laser perforation a recognized security standard for document manufacturers and authorities.

Material diversity and precise results with laser perforation

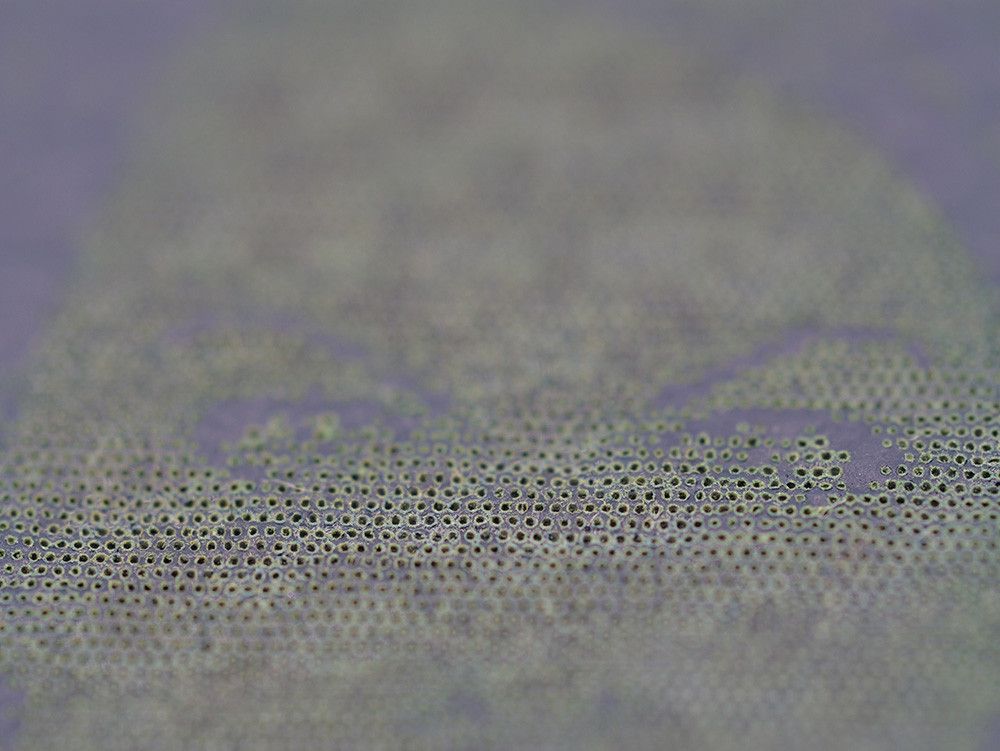

Laser perforation is suitable for a wide range of materials and opens up a variety of application options - precise, gentle on the material and without mechanical contact. Plastics can be structured to integrate functions such as ventilation or opening aids. Leather can be microperforated, for example to improve breathability or as a decorative design element. Textiles, paper composites or technical films also benefit from non-contact processing - whether for functionalization or for targeted weakening of defined areas.

Our laser modules can be used flexibly: as an integrated solution in existing production lines or as stand-alone systems - scalable, efficient and tailored to your material requirements.

Application areas

at a glance

Material diversity and precise results

with laser perforation from MackSmaTec

Laser perforation is suitable for a wide range of materials and opens up a variety of possible applications - precise, gentle on the material and without mechanical contact. Plastics can be structured to integrate functions such as ventilation or opening aids. Leather can be microperforated, for example to improve breathability or as a decorative design element. Textiles, paper composites or technical films also benefit from non-contact processing - whether for functionalization or for targeted weakening of defined areas.

Our laser modules can be used flexibly: as an integrated solution in existing production lines or as stand-alone systems - scalable, efficient and tailored to your material requirements.

Advantages of our

laser perforation

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

High-Quality Solutions for Demanding Tasks

Reliable and precise mechanical engineering solutions are required in every industry. We ensure that your processes run smoothly and with maximum efficiency – no more and definitely no less.