Customized

Manufacturing Solutions

for OEM Partners.

As an experienced mechanical engineering company, we offer OEM customers a reliable full-service offering in the manufacture of assemblies, modules and complete systems.

You benefit from our high level of vertical integration, state-of-the-art production infrastructure and decades of engineering expertise – all from a single source and made in Germany.

Our focus is on partnership-based cooperation: we understand your requirements, speak your language and deliver exactly what makes your brand strong – efficiently, precisely and on time.

Complete Solutions for Machine Construction and Automation

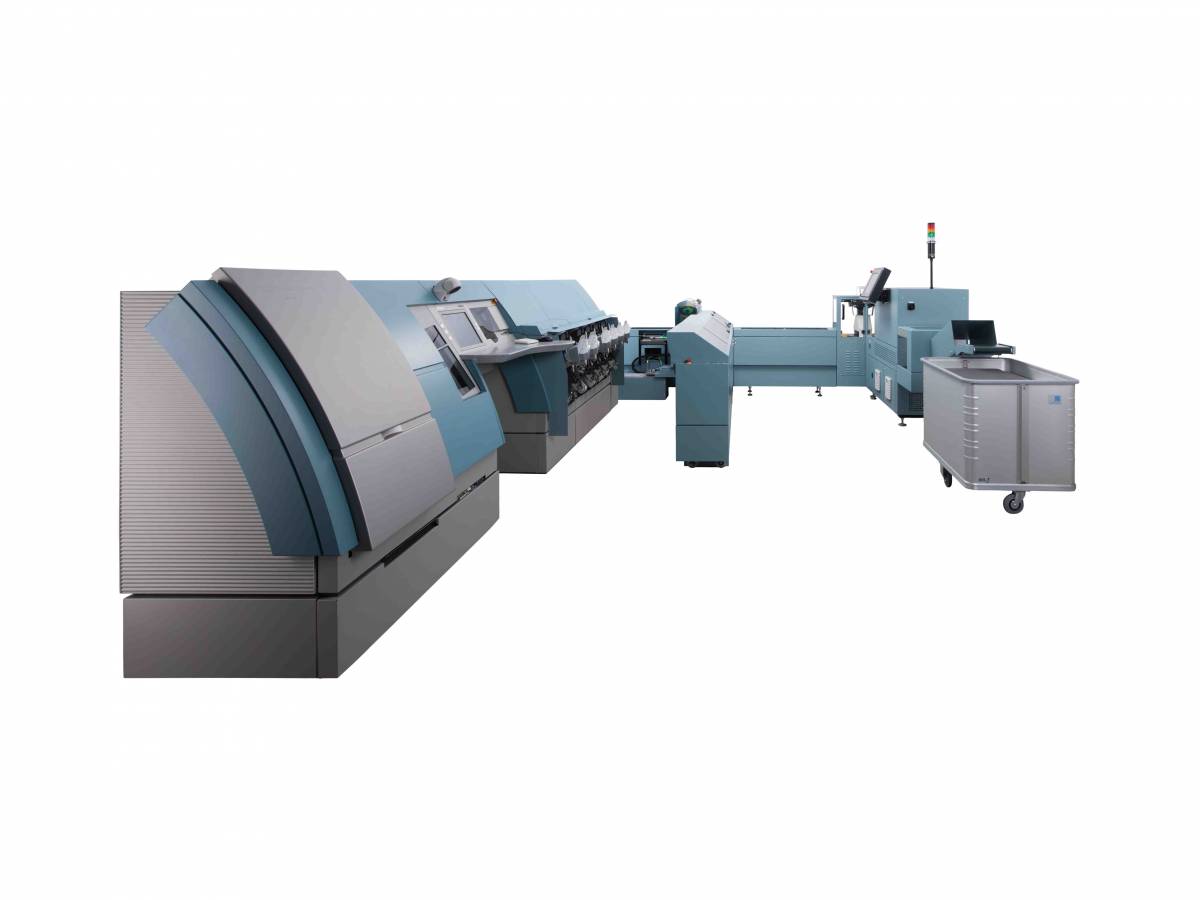

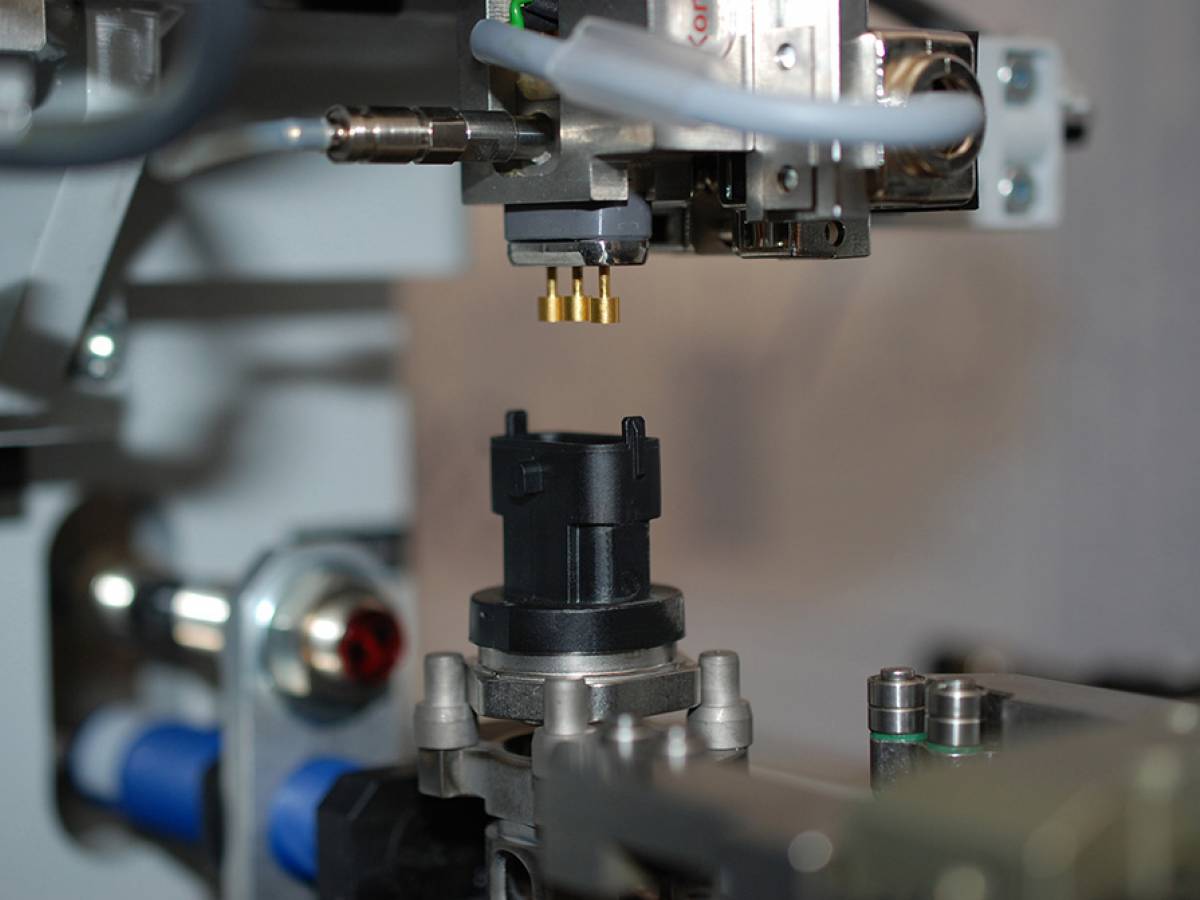

From design, manufacturing, assembly, programming and commissioning to final testing – MackSmaTec takes care of every step of your OEM production. We also provide reliable after-sales support with technical assistance, spare parts and customisations. Our manufacturing capacities are flexibly scalable – whether for small series or large orders – and guarantee consistently high quality and delivery reliability. At our site in Thuringia, we focus on continuous quality control, technological precision and absolute confidentiality – contractually guaranteed on request.

Benefit from

Scalable production capacities: from small series to large orders

Made in Germany: We combine quality, innovation and reliability.

Confidentiality and brand protection: Your product, your brand, our promise of protection.

Your Benefits of an OEM Partnership with MackSmaTec

We have been developing and producing systems for leading industrial customers worldwide for over 30 years - always at the cutting edge of technology.

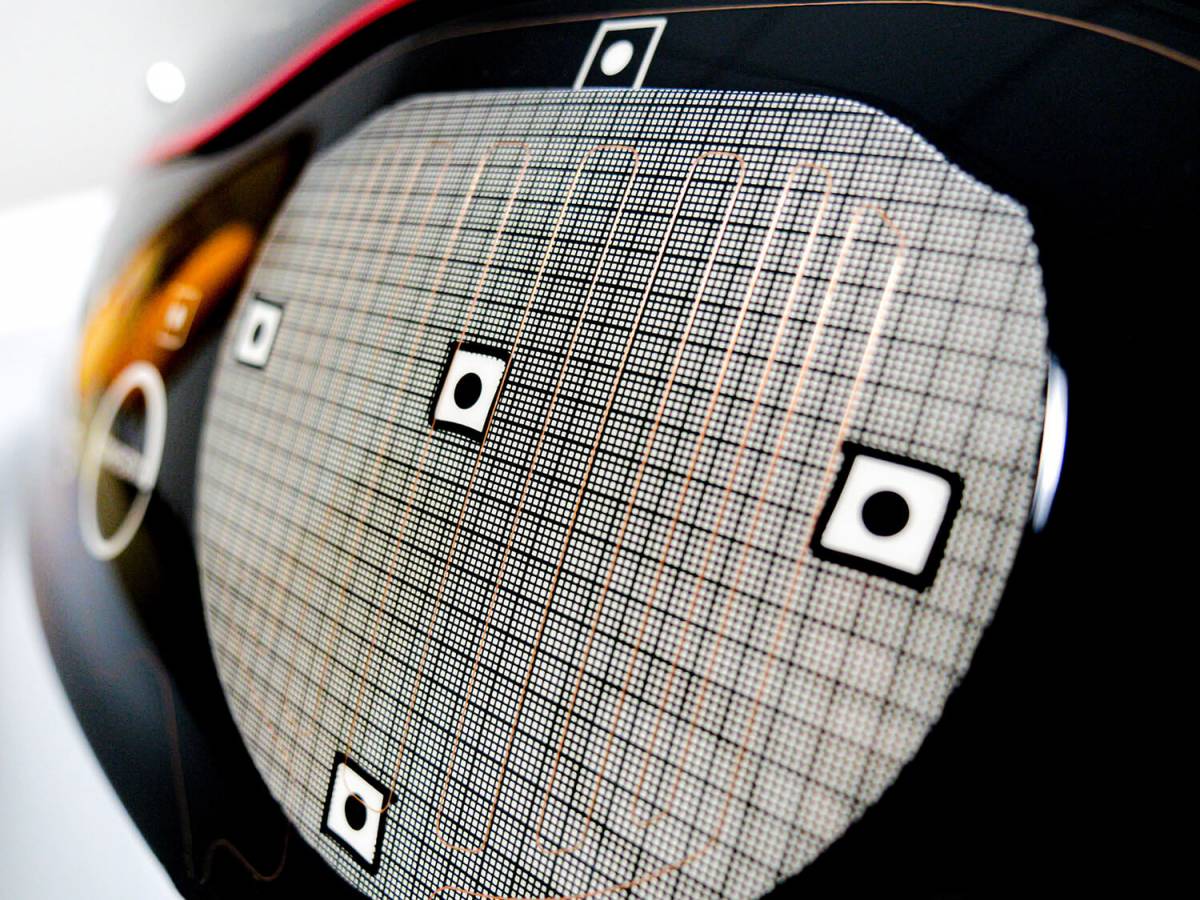

Our expertise ranges from precision mechanics and control technology to software integration - the ideal foundation for complex OEM projects.

We rely on close coordination, short decision-making processes and transparent communication - from the first contact to series delivery.

We also support your systems after series production. Through continuous analysis and optimisation, we ensure the long-term performance and competitive strength of your products.

Scalable production – from prototype to series production

Whether prototype production, small series or large orders: thanks to our flexible production infrastructure, we can adapt precisely to your needs. Our 10,000 m² production area offers space for efficient workflows, structured process zones and parallel production lines. This enables us to realise a wide variety of batch sizes – without compromising on quality, adherence to delivery dates or cost efficiency.

Rely on our in-depth manufacturing expertise

Our high level of vertical integration is the foundation of our OEM performance. We combine all essential machining and finishing processes at our own site – from sheet metal working and machining to surface finishing.

With state-of-the-art Trumpf sheet metal processing equipment, powerful CNC machining technology and our own in-house paint shop, we realise even the most demanding projects with consistent quality. Short distances, coordinated processes and a high degree of vertical integration ensure maximum precision and flexibility – for every batch size.

OEM with MackSmaTec – How the Collaboration Works

Talk to Us!

Are you an OEM looking for a manufacturing partner who understands your requirements and thinks along with you? Then talk to us – together we can get your products ready for series production.

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.