Modular Systems

for the Complete

Chip Module Production.

With our modular system solutions, we offer you an end-to-end process chain for the production and quality assurance of chip modules, from lamination and encapsulation to testing and personalization.

The MackSmaTec systems offer a powerful and flexible solution for chip module production. Their modular design allows easy adaptation to individual requirements. With throughput rates of up to 77,000 modules per hour, they enable maximum productivity.

Integrated inline quality controls ensure consistently high quality at minimum unit costs. Energy-efficient UV LED technology reduces consumption and extends the service life of the components. Intuitive touchscreen operation and the compact design facilitate integration, operation and maintenance during operation.

Our Solutions

at a Glance

- Up to 40,000 modules/hour

- Process types: Fill, Dam & Fill or Fill & Fill

- Curing by UV LEDs

- Automatic spool system for 35 mm modular tapes

- 12-fold and 16-fold dosing heads

- High dispensing accuracy

- Automated inline quality control

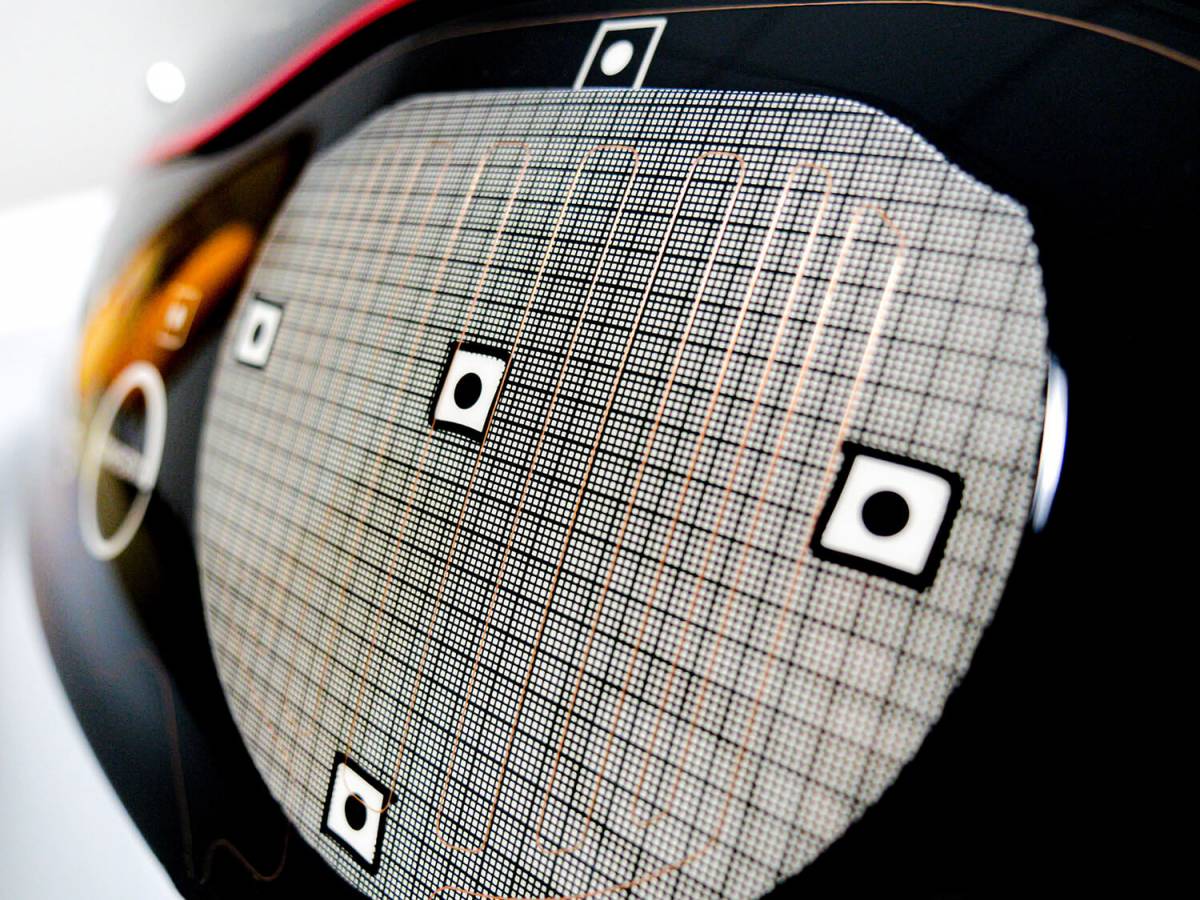

PowerSeal - High-Speed Encapsulation with UV LED Technology

The PowerSeal is optimized for the precise and fast encapsulation of chip modules and offers high performance and, above all, flexibility in curing. In addition to UV LED technology, UV discharge lamps or heating elements can also be integrated depending on the process requirements.

The machine is particularly suitable for high-volume applications where precise control of the module geometry and height is essential. Expandable inspection systems enable seamless inline control of the potting quality. The PowerSeal is an ideal solution for the production of electronic health cards with sensitive security chips, where reliable protection by potting material is essential.

- up to 77,000 chip modules/hour

- Automatic coil system for 35 mm modular tapes

- Contact: up to 128 test heads

- Contactless: up to 48 test heads

- Dual Interface & Coil on Module: up to 32 test heads

- Flexible reel-to-reel system

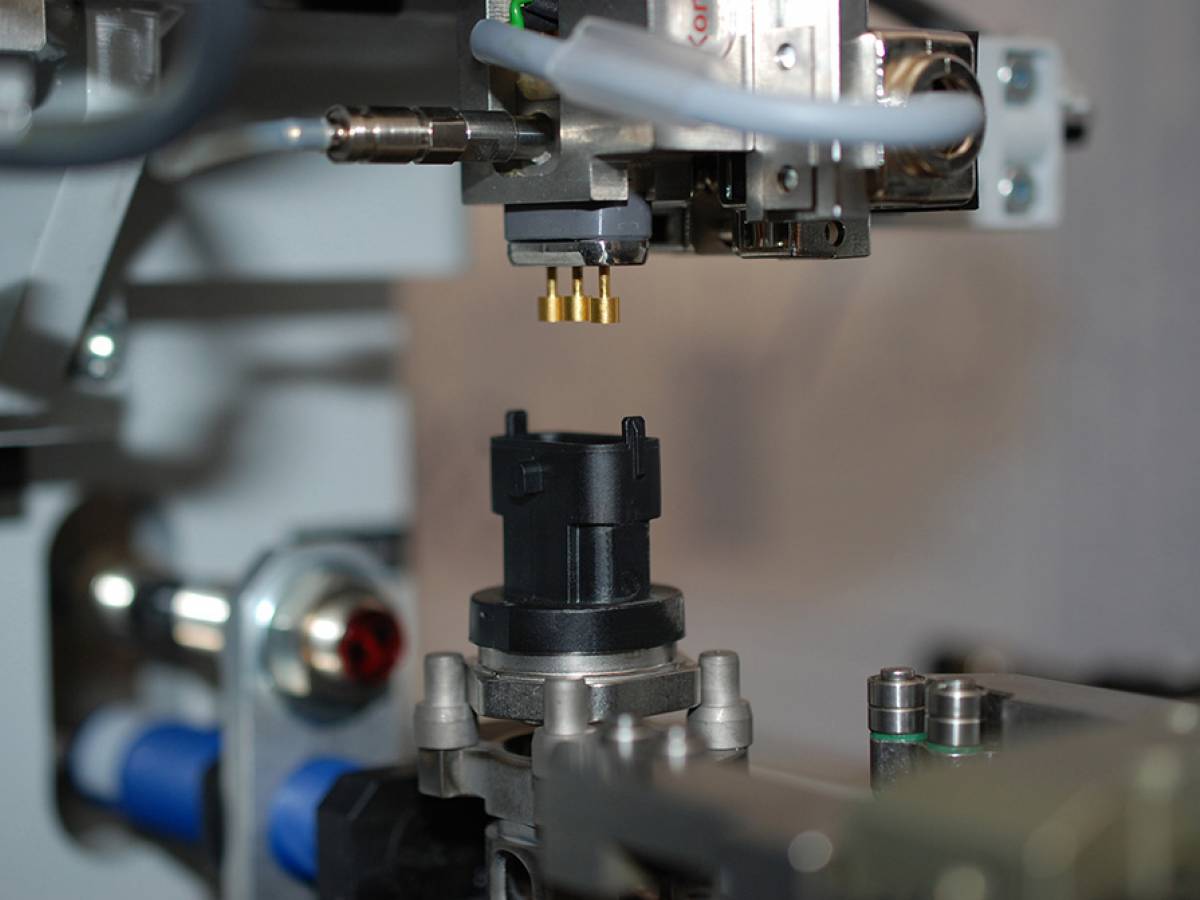

PowerTest - Versatile Testing and Personalization System

The PowerTest is a scalable test system for parallel processing of large quantities of modules - ideal for high-end personalization processes. Its special feature is its universal test capability for contact, contactless and dual interface modules.

In addition, the platform enables the integration of individual customer solutions, for example by integrating external test software or electrically isolated processing logic – an advantage for safety-critical or complex personalization applications.

The electrical initialization and individual personalization of contactless payment cards with encrypted security modules is possible without any problems using PowerTest.

- Up to 8,000 chip modules/hour

- Reels for 35 mm module tape, protective film and adhesive tape

- 6-fold and 10-fold tools for punching and laminating

- For all chip module types and sizes, including dual interface

- Individual setting of temperature, time and pressure

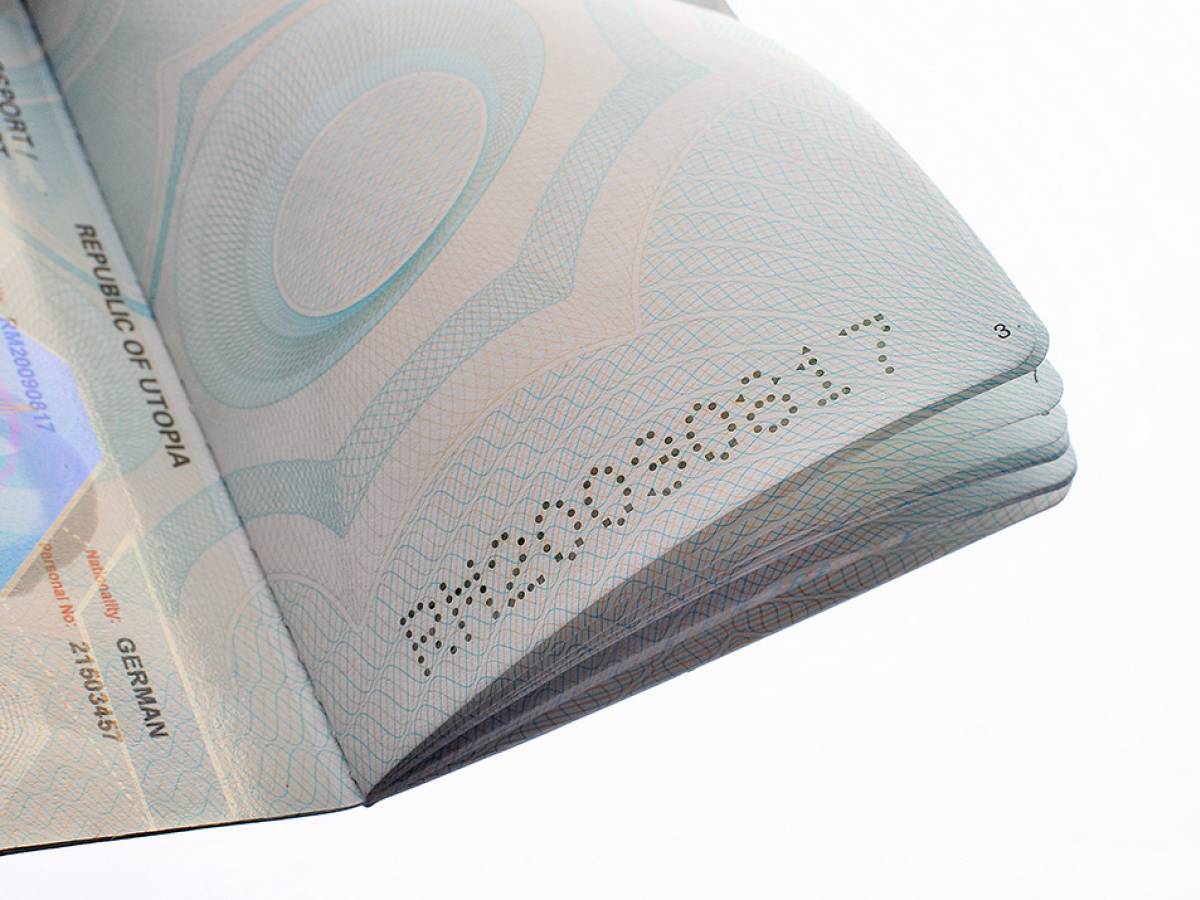

GTL700 - Precise Adhesive Tape Lamination

The GTL700 is a specialized system for adhesive tape lamination of modular tapes. Its strength lies in the precise preparation of the chip modules for the subsequent implantation process. Particularly noteworthy are the configurable reel options, which allow flexible handling of different material types and protective films.

The lamination station control allows individual adjustment of temperature, time and pressure – ideal for adapting to different types of adhesive tape and requirements. The GTL700 is used in the production of dual-interface chip cards, where precise lamination processes are crucial for the connection between the contact and antenna unit.

Advantages of Our

Chip Module Production

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

Sales Card & Passport Systems +49 36925 929-322 Get in Contact now

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.