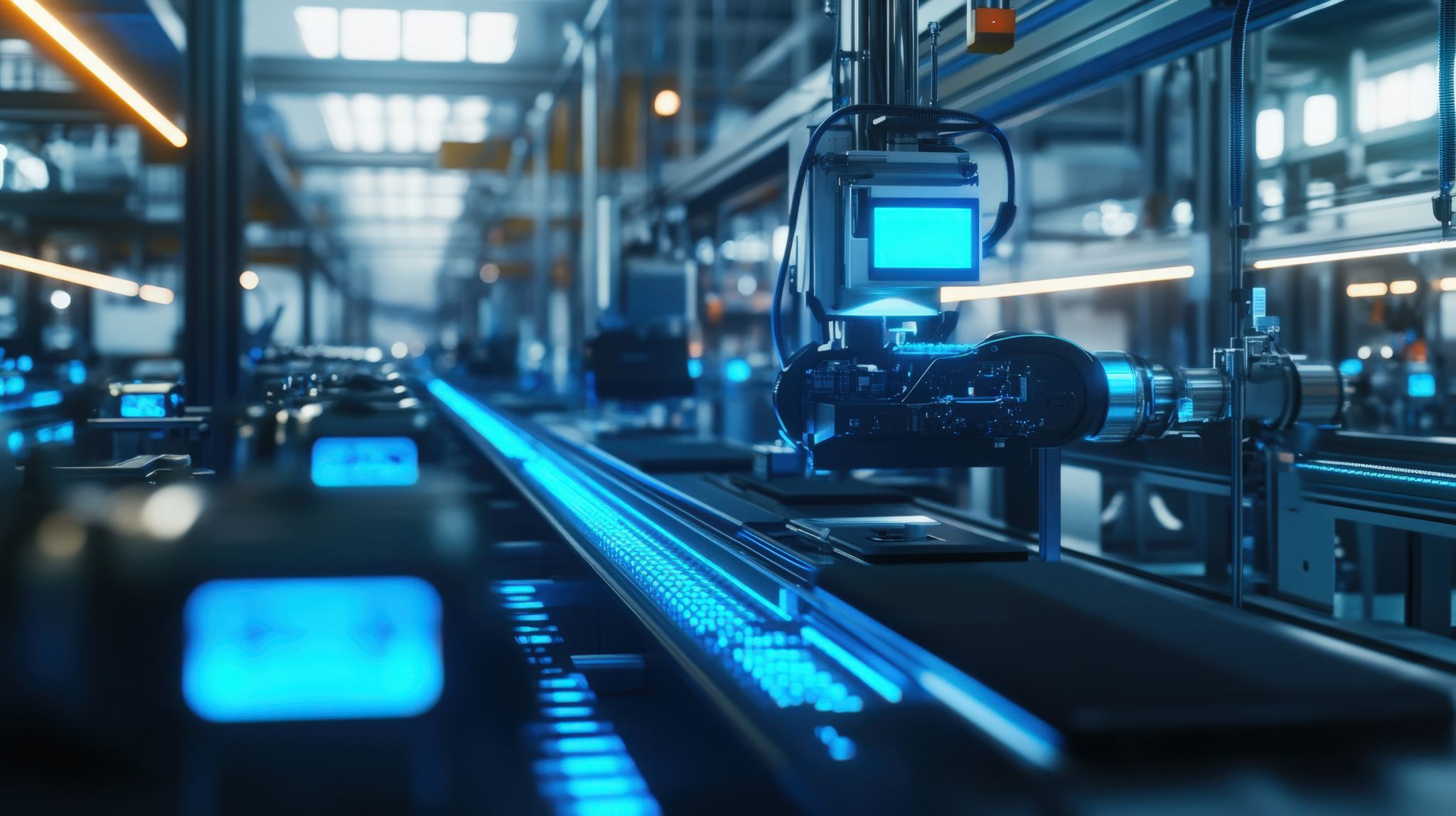

Digital Production with MackSmaTec.

More Efficiency, Transparency and Control.

From the individual machine to the entire networked system: our digital solutions make your production more transparent, efficient and resilient with condition monitoring, line control and MES from a single source.

Our Digital Solutions

at a Glance

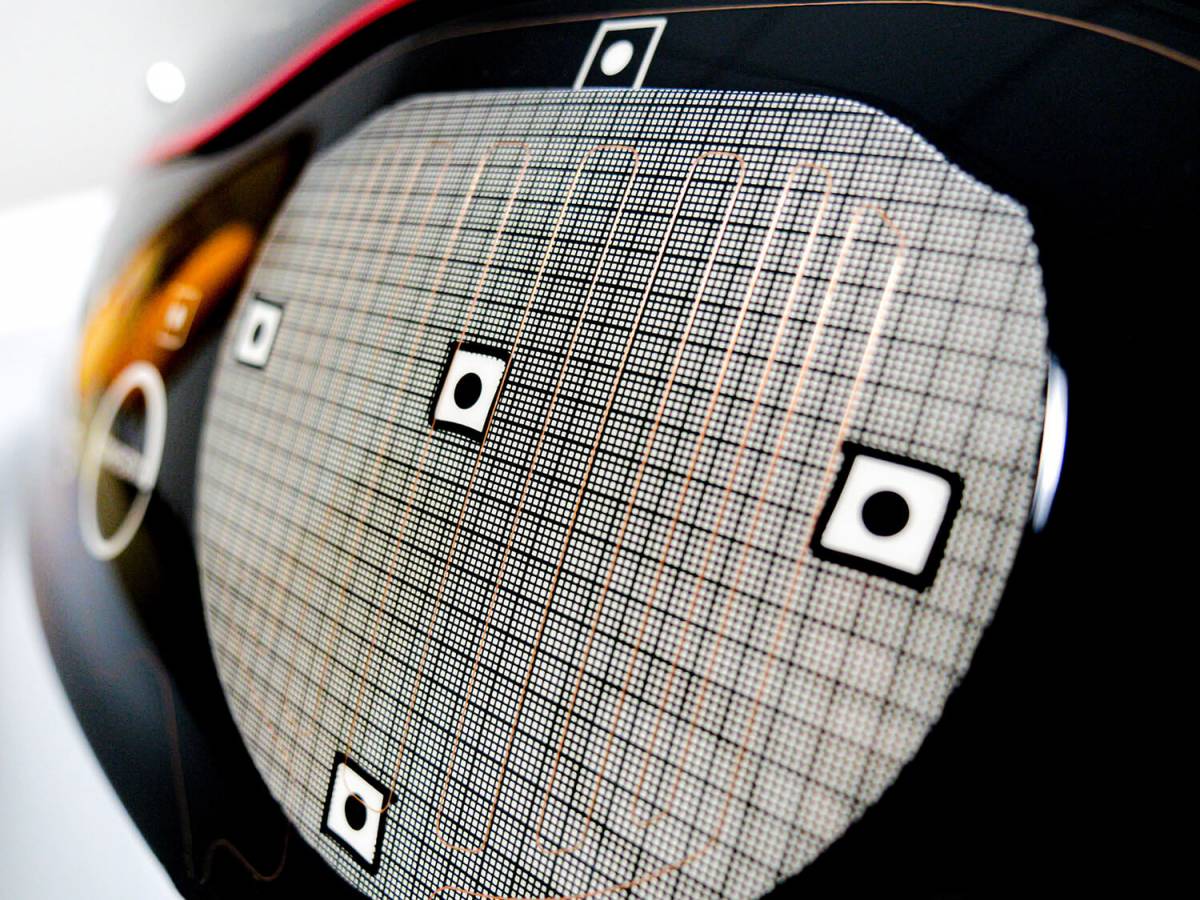

Condition Monitoring

Transparency, Availability, Efficiency.

Condition monitoring enables predictive maintenance based on continuous data analysis directly from your production. Relevant operating parameters such as temperature, vibrations or energy consumption are recorded and evaluated in real time and linked to key performance indicators (KPIs). This allows deviations to be detected at an early stage, unplanned downtimes to be avoided and maintenance to be carried out as required – for improved system availability, a longer service life for your systems and lower maintenance costs.

Your benefits:

React at an early stage: Anomalies are detected before they lead to failures.

Condition-based maintenance: Maintenance is carried out as required - saving time and costs.

Increase performance: Higher system availability, less downtime and measurable quality improvement.

Smart use of data: KPIs enable well-founded decisions, bottleneck elimination and continuous optimization.

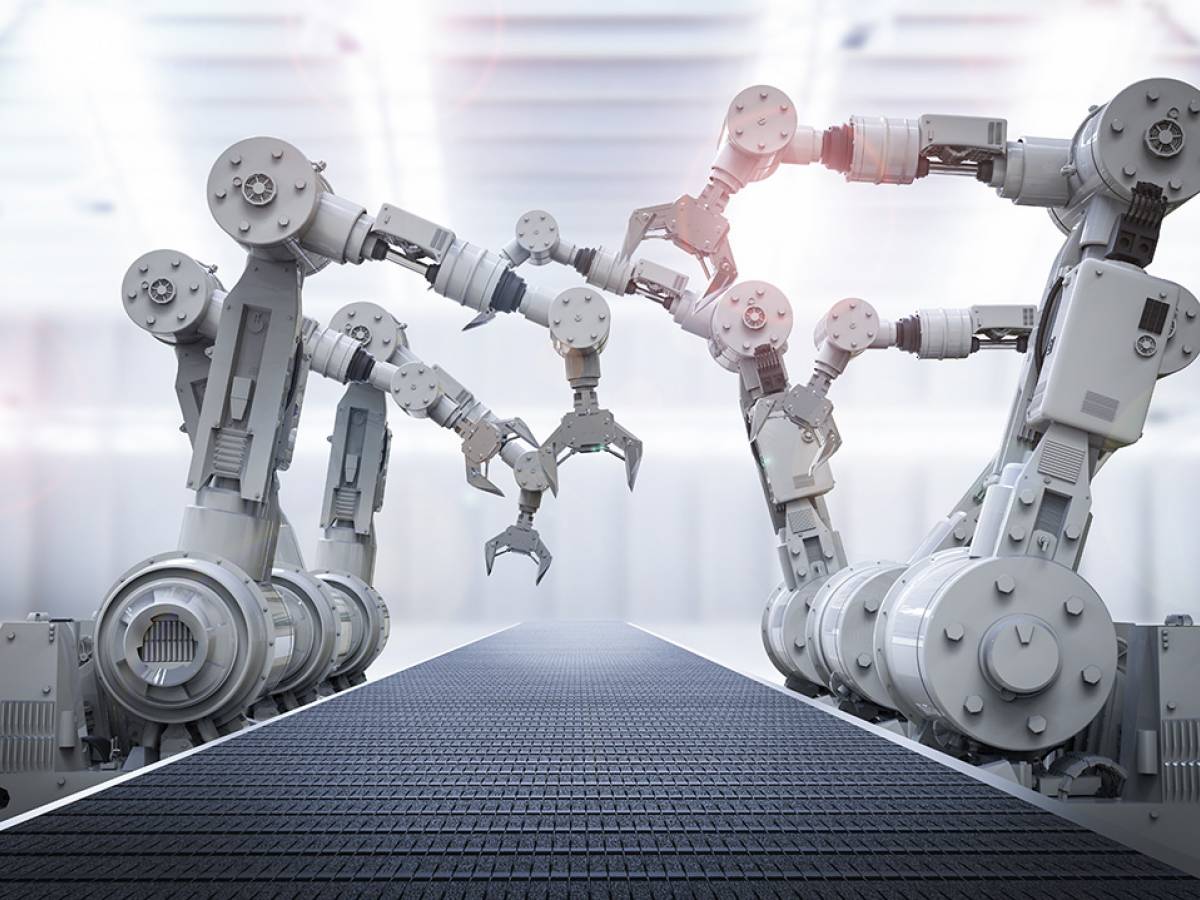

Line Control

Intelligent Production Control for Maximum Capacity Utilization

With Line Control, you can control and monitor your entire production line - from individual machines to networked systems - precisely and efficiently. The system ensures stable processes, minimal downtimes and full transparency across all processes. This lays the foundation for responsive, economically optimized and future-proof production.

Your added value:

Precise control: Synchronization of all components - machines, conveyor belts, robots - for a smooth process.

Real-time monitoring: Continuous monitoring of production speed, material consumption, capacity utilization and product quality.

Automated control: Dynamic adjustment of process parameters such as speed, temperature or pressure to ensure product quality.

Fault detection & rectification: Early detection of faults with automatic response - from warning messages to process adjustment.

Production optimization: Maximization of line utilization, reduction of errors and rejects, improvement of overall productivity.

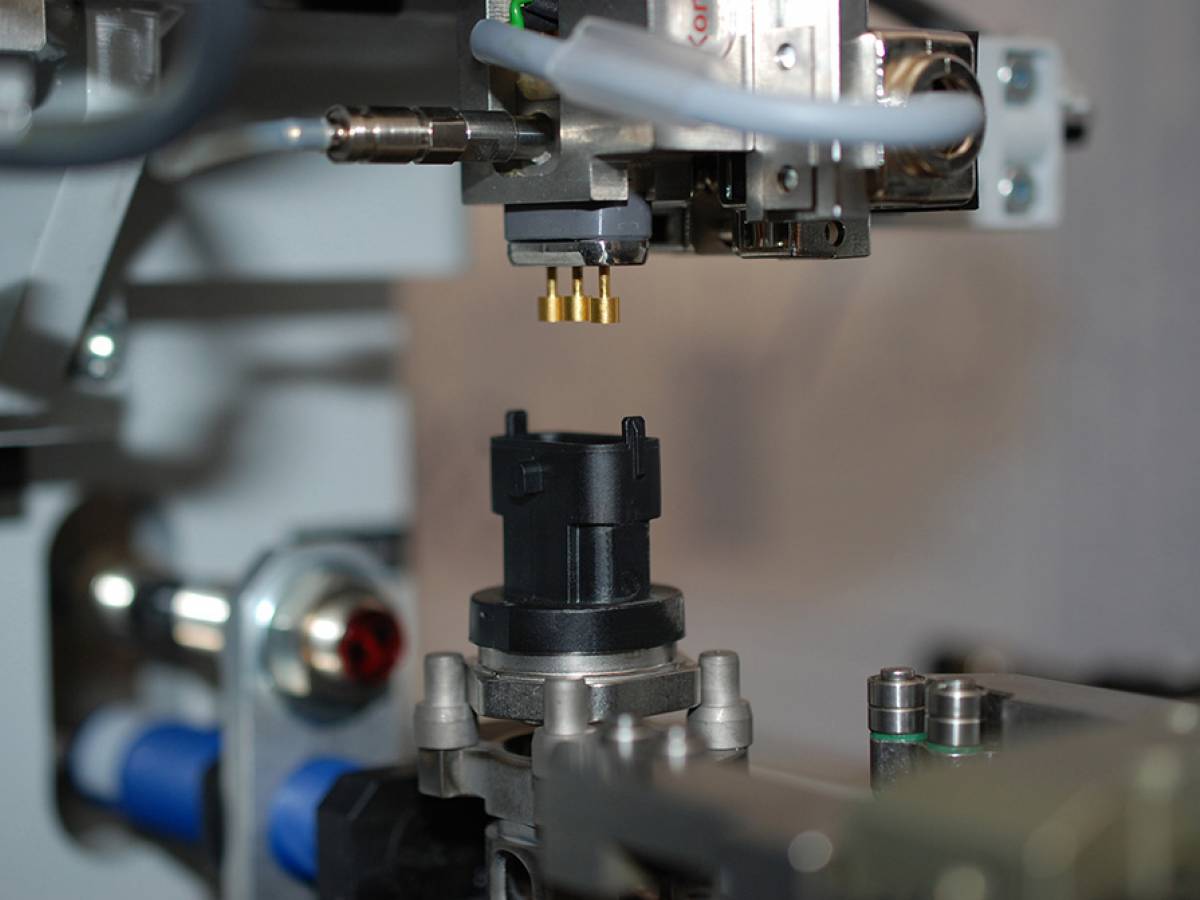

Manufacturing Execution System (MES)

Real-Time Control for Your Production

Our MES (Manufacturing Execution System) combines operational production with digital intelligence. It plans, controls and monitors your production processes in real time, creating the basis for efficient, flexible and fully traceable production. With direct access to all relevant process data, MES as a central control system or modular extension helps you to precisely control orders, make optimum use of resources and systematically ensure quality.

Lay the foundation for MES:

Digital production planning and control: Optimal scheduling, resource allocation and sequencing of your orders.

Order tracking in real time: Complete transparency on status, progress and capacity utilization.

Material management: Monitor stocks, forecast requirements, coordinate deliveries.

Quality control: Continuous data collection and automated deviation analysis for fewer rejects and stable processes.

Traceability and compliance: Seamless documentation across all production stages.

Performance analysis: Preparation of all production data for targeted optimization and continuous improvement.

Your Advantages at a Glance

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.