Precise Inspection for the Highest Quality and Safety Requirements.

Automated Optical Inspection (AOI) is the key to efficient, automated quality control in industrial manufacturing processes – from electronics production to the issuing of security-relevant documents such as ID cards or passports.

With high-resolution camera systems, intelligent image processing and multispectral lighting, our AOI solutions detect even the smallest deviations – quickly, reliably and inline.

Applications

in the Industry

Our AOI Systems Are Used in

Numerous Industries:

(SMT/PCB)

2D and 3D inspection for the detection of soldering defects, missing components or position deviations.

Quality control, surface inspection, weld seam analysis and dimensional inspection of complex components.

Completeness check of labels and markings, glass inspection of vials or syringes.

Testing for dimensional accuracy, material defects or contamination - even with transparent materials.

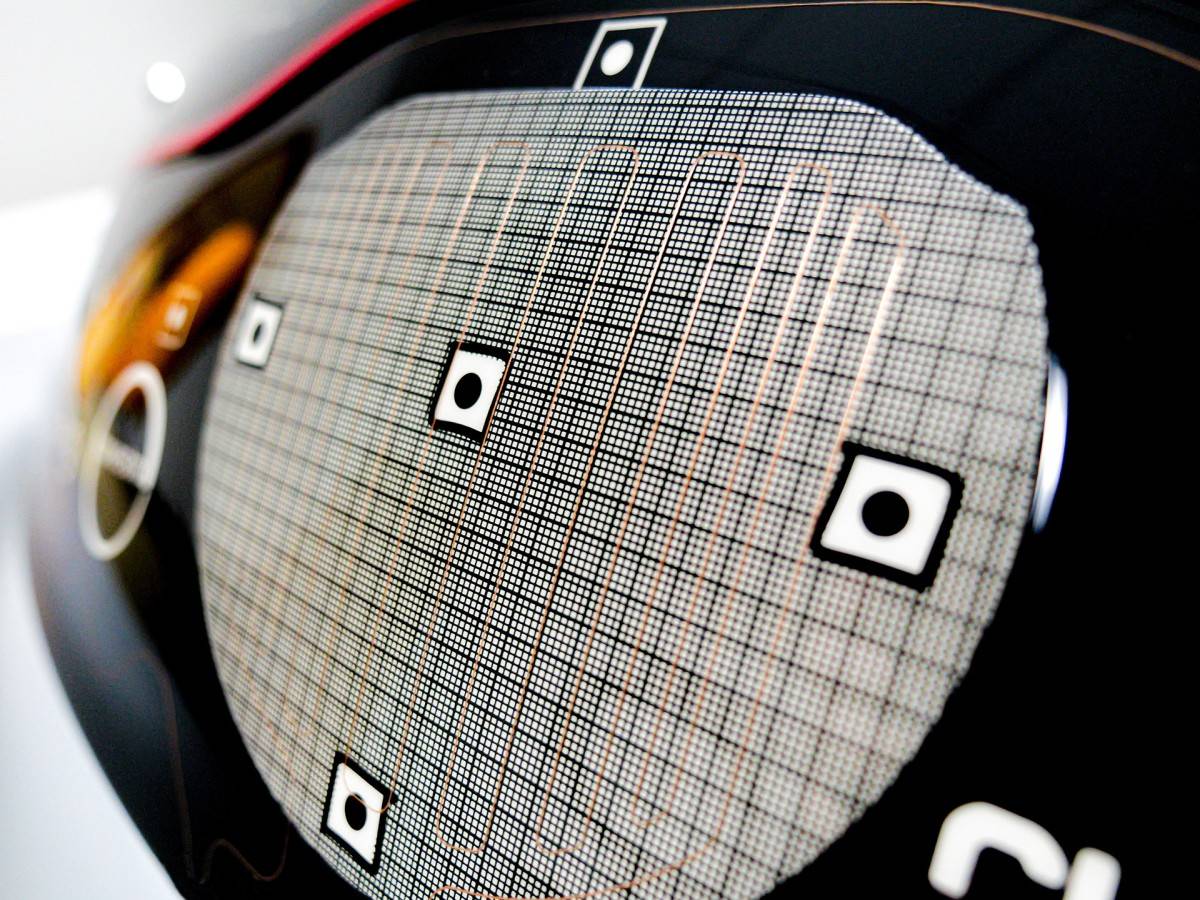

High Security Check for

ID Cards and Passports

Maximum precision and security are required in the production of ID cards and passports. Our AOI systems support you in the:

Verification of security features

Checking of holograms, UV prints, optically variable elements and microtext.OCR/MRZ recognition & data matching

Automatic verification of personal data including biometric matching and machine-readable zones against production data.Multispectral imaging

Recognition of security features under UV, IR or visible light.

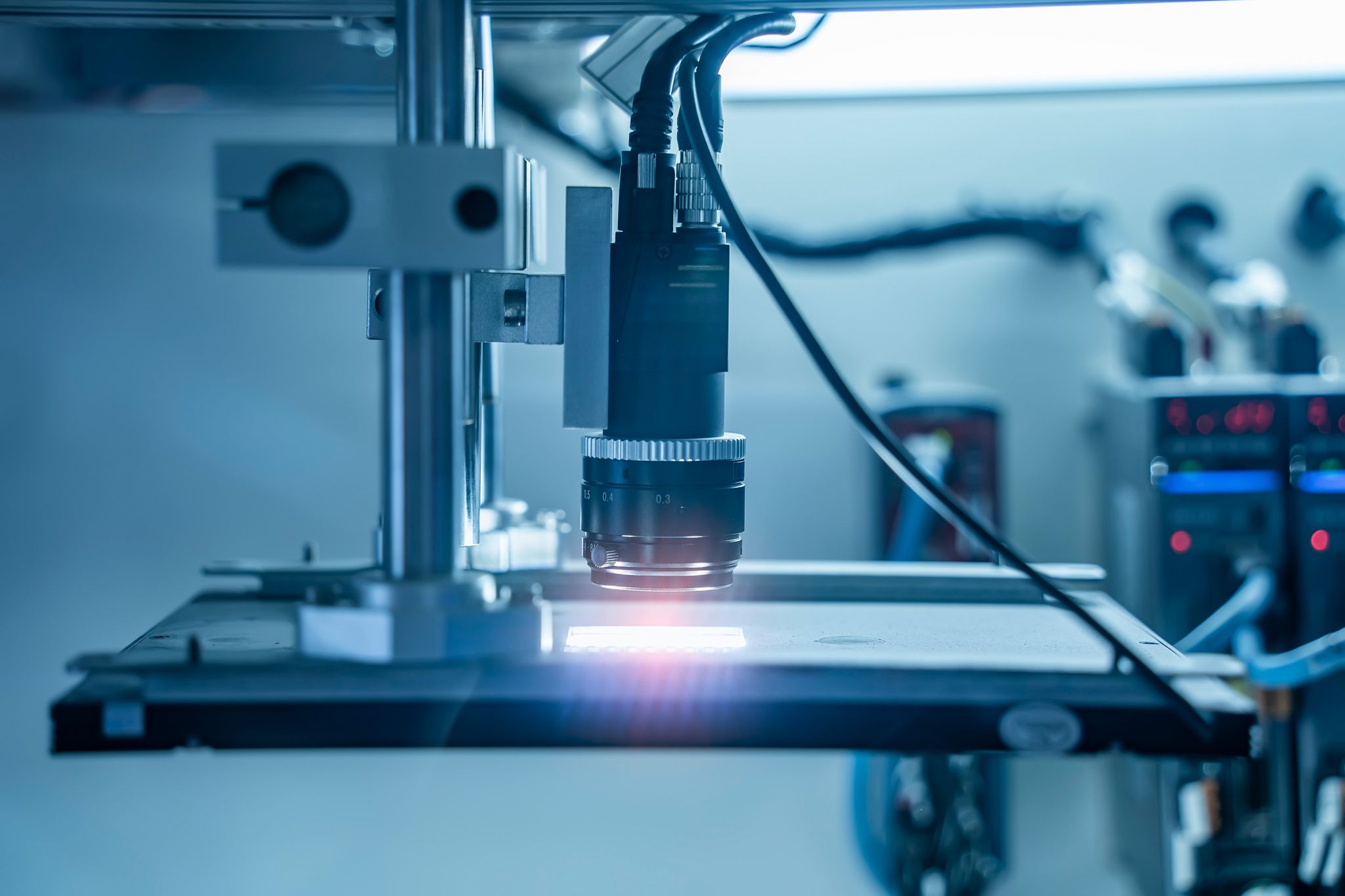

Technology That Thinks Ahead

Our AOI solutions are based on state-of-the-art technology: high-resolution 2D and 3D camera systems with a resolution of up to 21 megapixels are used, which are connected via high-performance interfaces. Optimal detection of even the finest details is ensured by lighting and the selection of optical components adapted to the task in hand. In addition to classic white light LED illumination, adapted wavelengths from the UV to the IR light range, as well as multispectral LED illumination, are also used.

When processing the captured image data, we rely on our many years of experience in conventional image processing and, where necessary, expand this with modern AI-supported algorithms and AI applications. This makes it possible to specifically identify anomalies, compare features and analyze deviations in real time. Thanks to their modular design, our systems can be seamlessly integrated into existing production lines – for maximum efficiency with minimum effort.

Your Advantages

at a Glance

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

High-Quality Solutions for Demanding Tasks

Reliable and precise mechanical engineering solutions are required in every industry. We ensure that your processes run smoothly and with maximum efficiency – no more and definitely no less.