Vision Systems from MackSmaTec.

Modular, Automated,

Ready for Immediate Use.

In modern production, every detail counts. Our vision systems ensure precise error detection, reliable monitoring and intelligent data analysis to increase quality, efficiency and process availability.

Our Solutions

at a Glance

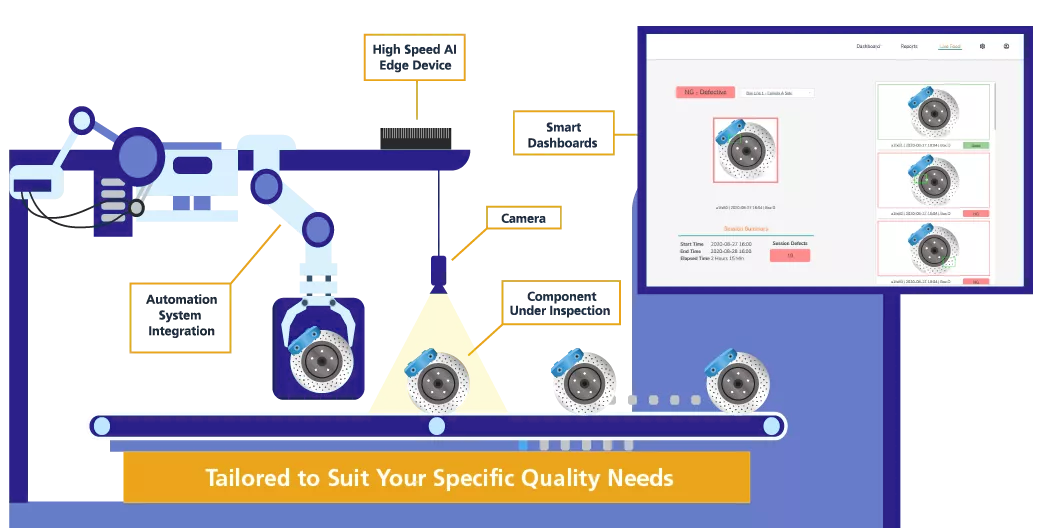

Smart Detect

Automated Quality Inspection with a System

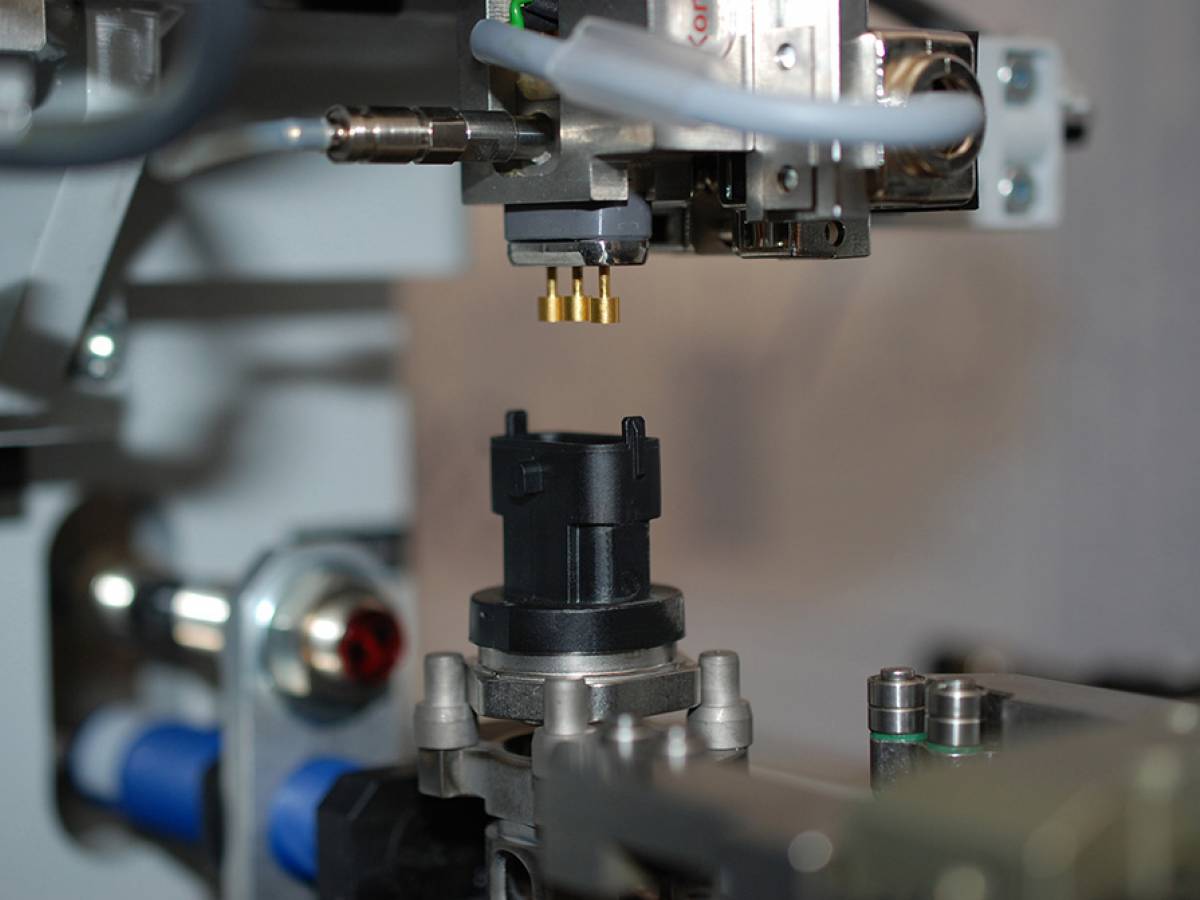

Smart Detect is your cost-effective solution for precise, flexible quality control - ideal for companies that want to develop their production in the direction of networked production.

Instead of time-consuming programming, the system is based on a structured training process in which relevant product features are recorded and classified. On this basis, Smart Detect reliably recognizes surface deviations and reacts with defined measures - from signals to line control.

Once trained, features can also be applied to similar or new products. This increases the adaptability of your inspection processes and sustainably reduces changeover times and inspection costs

Smart Edge Analytics

Efficient Data Evaluation Directly in Production

With Smart Edge Analytics, you can analyze production data where it is generated - directly on the machine, system or sensor. This means you avoid unnecessary cloud transfers, reduce the load on your infrastructure and gain valuable insights without wasting time.

Instead of storing all raw data centrally, the system automatically filters out the relevant information. This flows directly into analyses, maintenance strategies or KPI evaluations. Superfluous data is immediately discarded.

Decentralized real-time evaluation makes it possible to detect anomalies at an early stage, rectify faults more quickly and control maintenance cycles more precisely. This improves your production stability, reduces costs and makes your production more agile with reduced use of resources.

AI Vision

Deep Learning for Maximum Precision

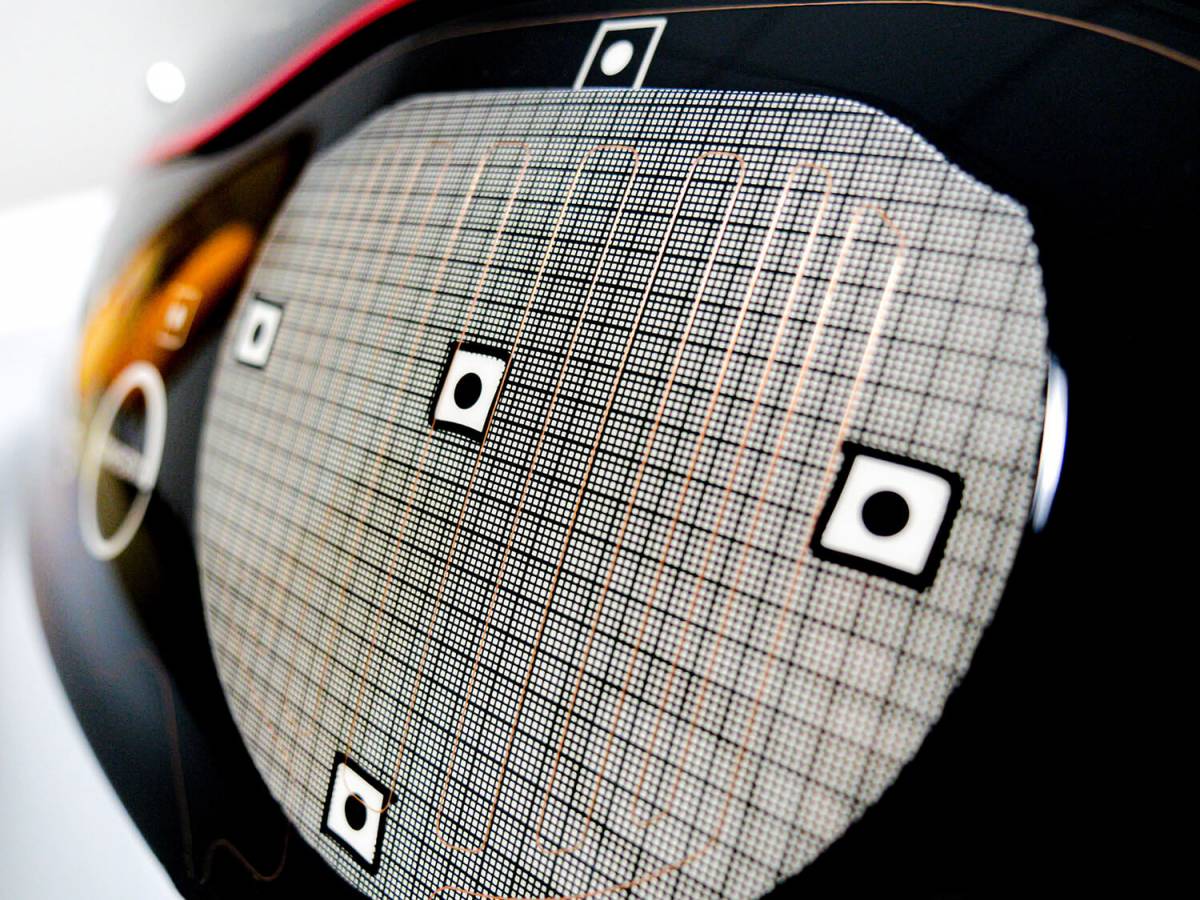

AI Vision takes advanced image processing to a new level. Using self-learning algorithms, the system analyses camera data in real time, detects precise deviations and provides well-founded findings to optimize quality, efficiency and process stability.

AI Vision enables new solutions, particularly where conventional inspection methods reach their limits - for example with natural materials, complex surfaces or in medical technology. The technology reduces manual inspection efforts, minimizes sources of error and measurably increases productivity.

Whether manufacturing, logistics, agriculture or healthcare - AI Vision can be used across all industries and scales with your requirements. As a result, you not only gain precision, but also speed and competitiveness.

Your Advantages at a Glance

Your Production Is Ready –

We Take Care of the Rest.

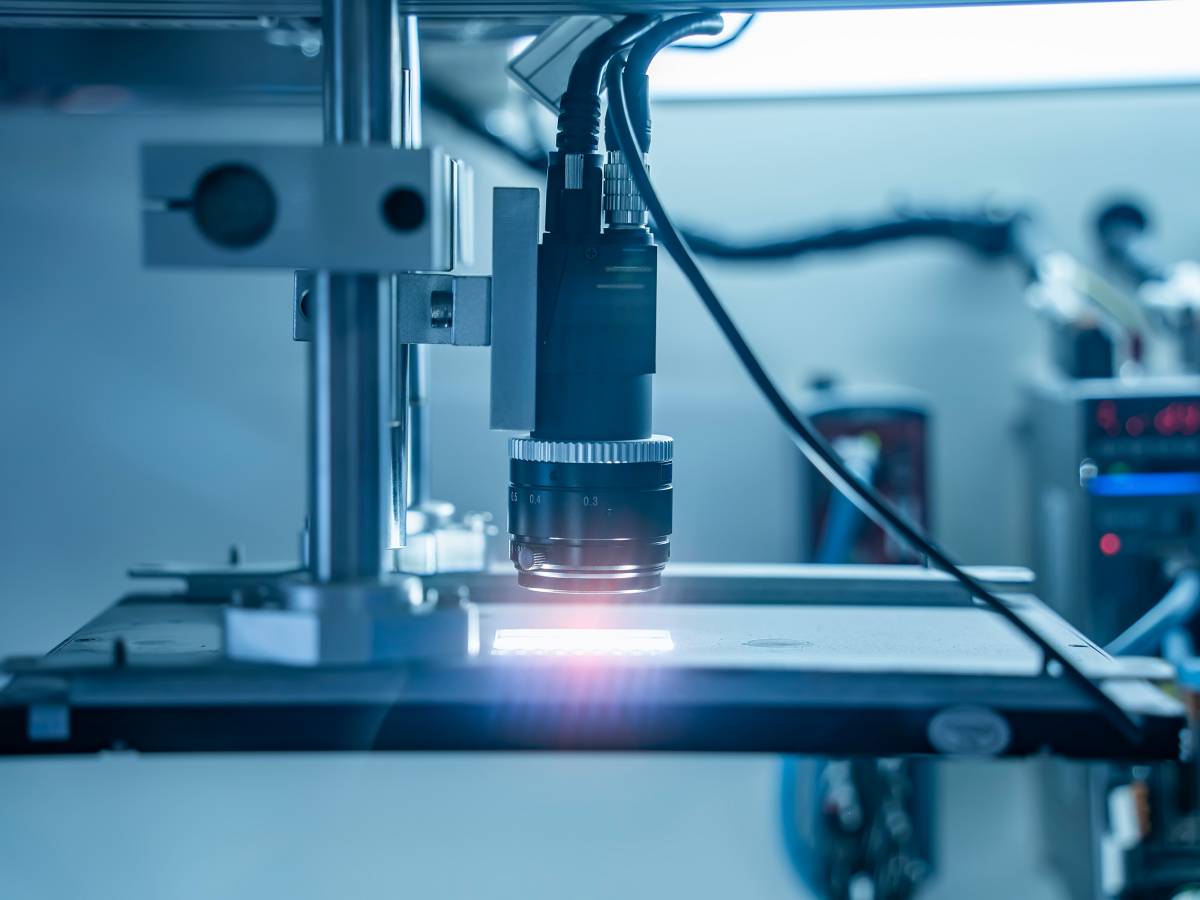

All you need to exploit the full potential of our vision systems is the right hardware basis: camera and lighting units, a PLC edge gateway and suitable interfaces for data communication.

Our experts will provide you with comprehensive advice on how these components can be optimally integrated into your existing infrastructure – efficiently, economically and future-proof. From planning to commissioning, we are at your side as a reliable partner.

Get in touch with us.

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.