Wire Embedding Technology

for 2D and 3D Applications.

Whether flat or spatial: MackSmaTec's wire embedding technologies can be used to produce both 2D and complex 3D wire structures precisely and automatically.

Our systems open up almost unlimited application possibilities – from sensor technology to electromobility and medical technology.

Thanks to modular platforms and intelligent control technologies, our solutions are ready for any challenge in smart production.

Our Technology

at a Glance

Use Case 1: De-Icing Systems for Vehicle Sensors and Components

Reliable De-Icing for Safety-Related Vehicle Sensors

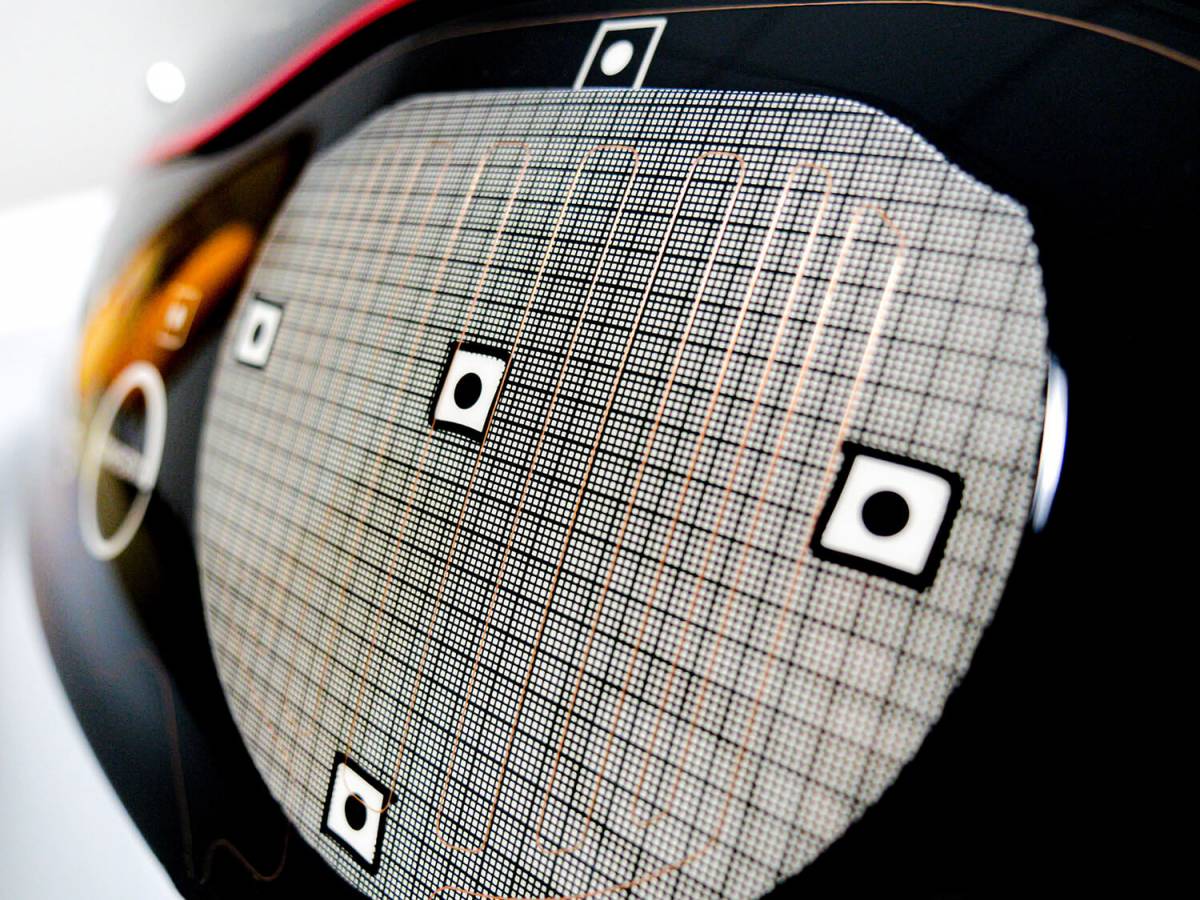

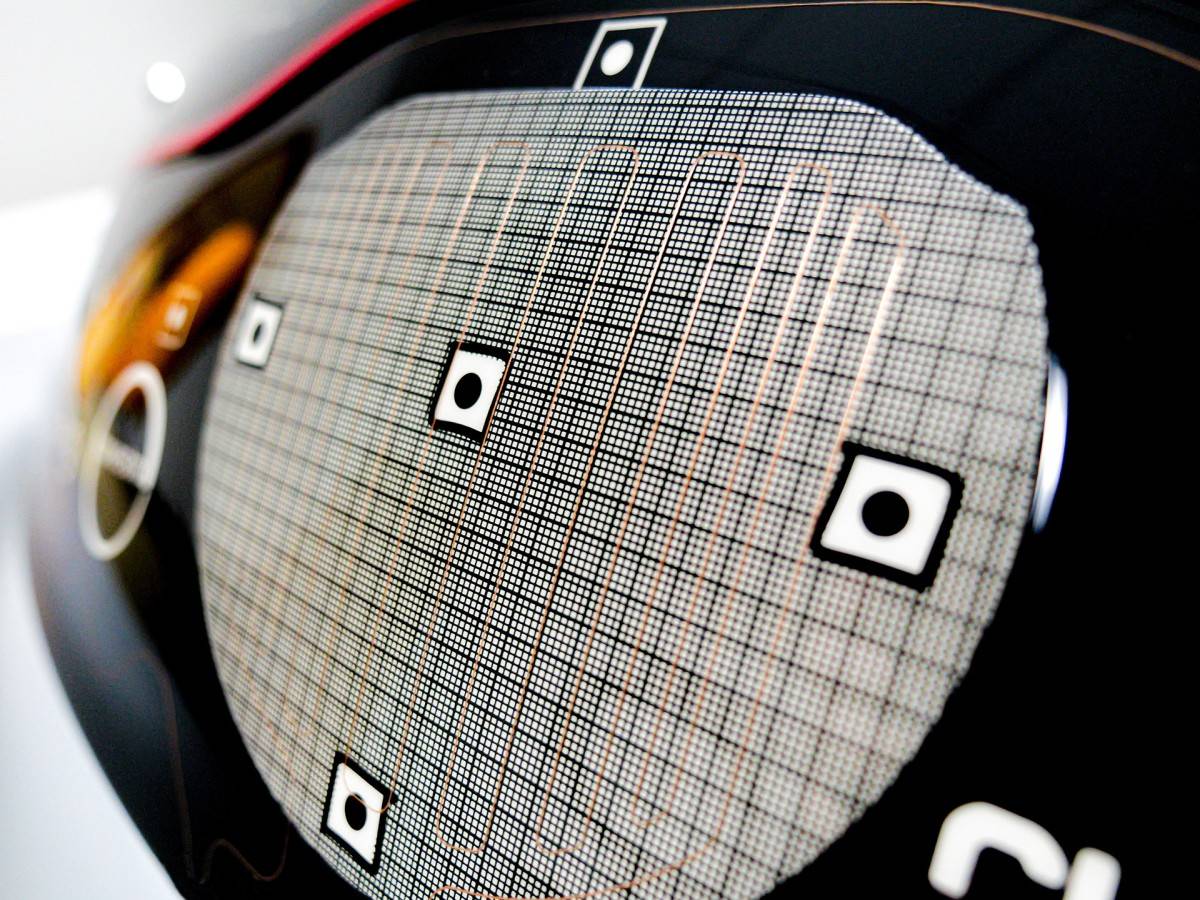

A clear view of sensors is essential in modern driver assistance systems - even in ice and snow. With the WCEvario3D, MackSmaTec creates precise 3D wire structures for the active heating of sensor covers, bumpers or headlight glazing. The automated embedding process on complex surfaces ensures homogeneous heat distribution, fast response times and high repeat accuracy even for large series.

Technology in use:

WCEvario3D with robot guidance, ultrasonic wire embedding, integration of temperature sensors

Industry:

Automotive (driver assistance systems, front modules, lighting systems)

Use Case 2: Invisible Interior Heating for Comfort Systems

Flexible Heating Solutions for Vehicle Interiors – invisibly integrated

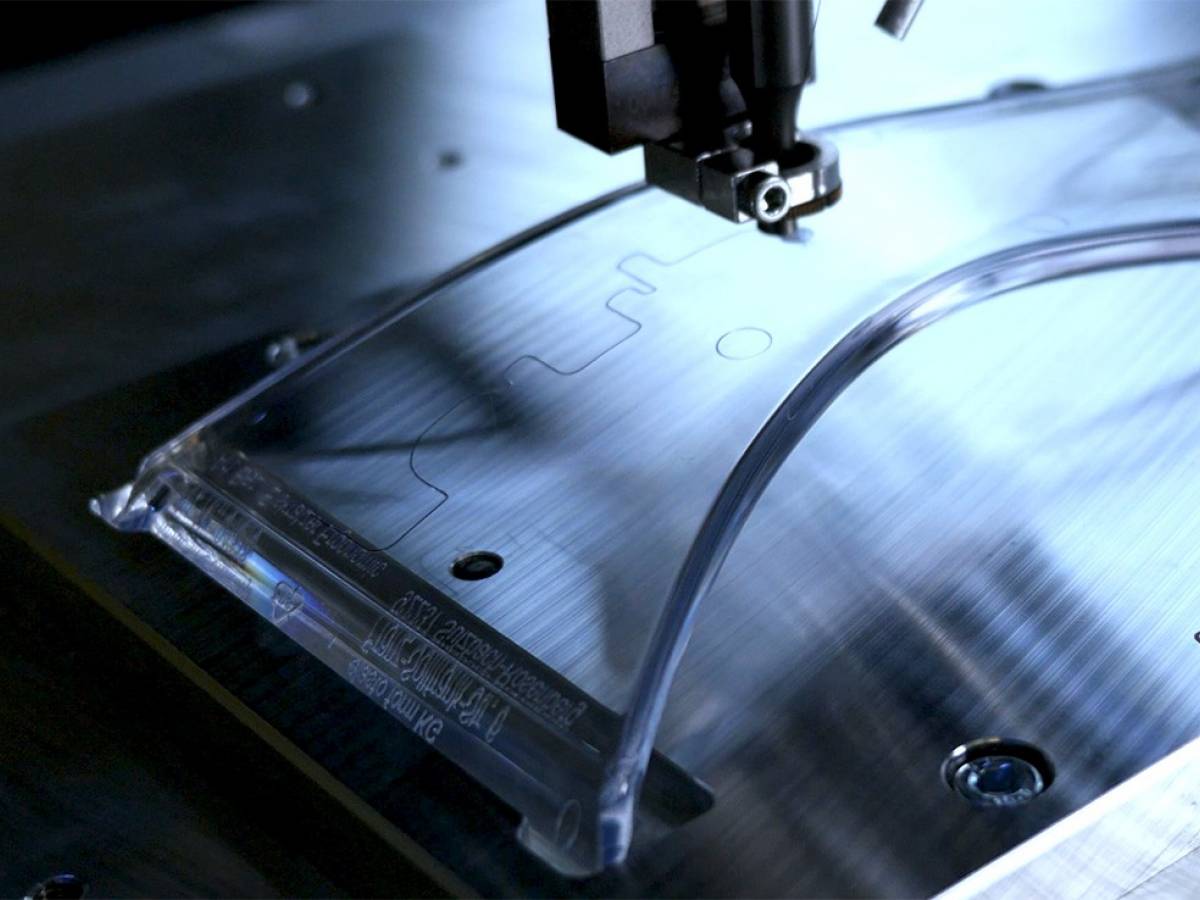

For modern vehicle interiors with a high degree of design freedom, MackSmaTec offers wire embedding technologies for integrating heating elements directly into surfaces such as dashboards, door panels or seat modules. With the WCE Large Format system, heating wires are embedded in carrier foils or textile materials with millimetre precision – ideal for seat, steering wheel or ambient heating.

Technology in use:

WCE Large Format for large-area 2D wire embedding, integration of pick & place and TC-Bonding

Industry:

Automotive (comfort systems, interior, premium vehicle lines)

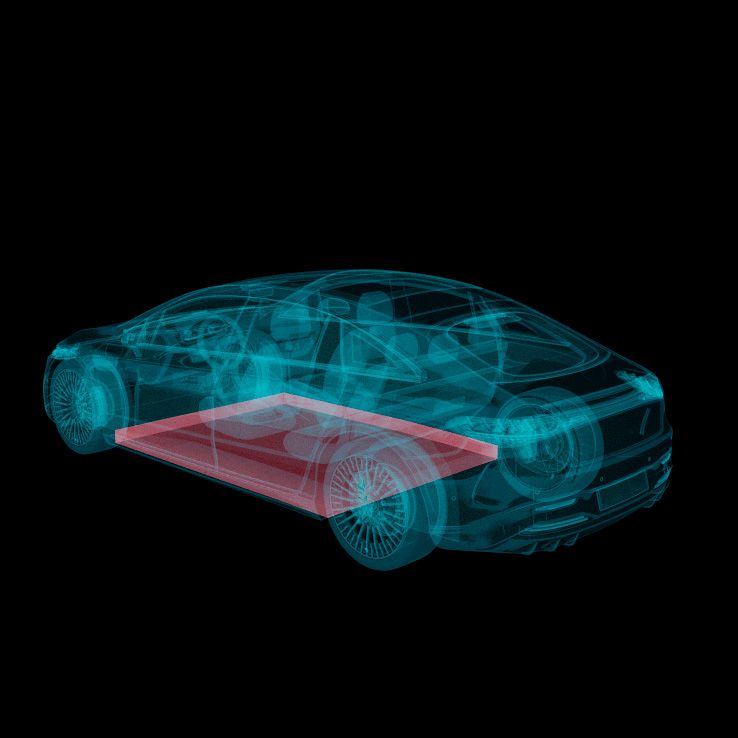

Use case 3: Temperature Management and Monitoring of Vehicle Batteries

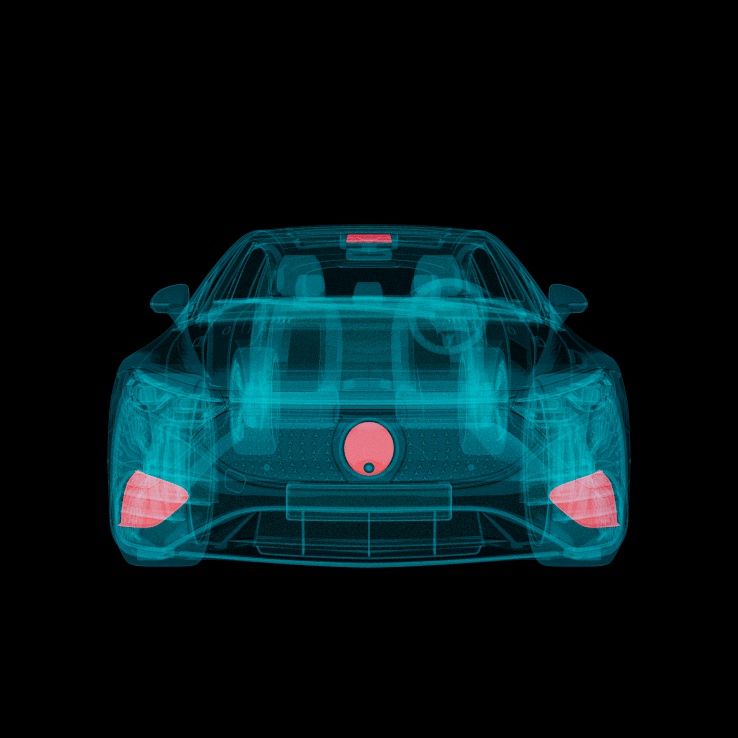

Efficient Heating and Sensor Technology for Electric Vehicle Batteries

Precise temperature management is crucial for the performance and service life of high-voltage batteries. With the WCEvario system, MackSmaTec develops functional wire structures for active battery heating and for embedding temperature sensors - integrated directly into thermally conductive carrier foils or plastic housings. The system enables fully automatic processing with simultaneous optical monitoring of each embedding process.

Technology in use:

WCEvario with ultrasonic wire embedding, integrated sensor cabling, inline control

Industry:

Automotive / electromobility (battery systems, thermal management, safety components)

Use case 4: Wire Integration on Films, Substrates and 3D Surfaces

Multi-Material Compatibility for Intelligent Films and Functional Carriers

Whether flexible films, rigid substrates or curved plastic shapes – MackSmaTec offers solutions for the precise embedding of wire structures on almost any substrate material. Our WCE Large Format and WCEvario3D systems and our RFID inlay production machine solutions process heating, sensor or conductor wires on thermoplastic films as well as on 3D-molded components with a high degree of geometrical freedom. This opens up a wide range of possibilities for intelligent surfaces in the automotive, consumer electronics and medical technology sectors.

Technology in use:

WCE Large Format for large-area 2D applications, WCEvario3D with robot guidance for 3D shapes, thermo-compression bonding (micro welding), solder joints, material recognition

Industry:

Automotive, medical technology, electronics industry (e.g. smart textiles, heating foils, capacitive control surfaces)

Let us advise you.

Our experts will be happy to support you in selecting the right solution for your requirements - individually, competently and personally.

High-Quality Solutions for Demanding Tasks

Reliable and precise mechanical engineering solutions are required in every industry. We ensure that your processes run smoothly and with maximum efficiency – no more and definitely no less.