Invisible, but Indispensable.

RFID Inlays for

ID Documents.

With our modular system solutions, we accompany you through all phases of RFID inlay production – from antenna production and module insertion to testing and personalization. We thus offer a seamless production and quality assurance process from a single source.

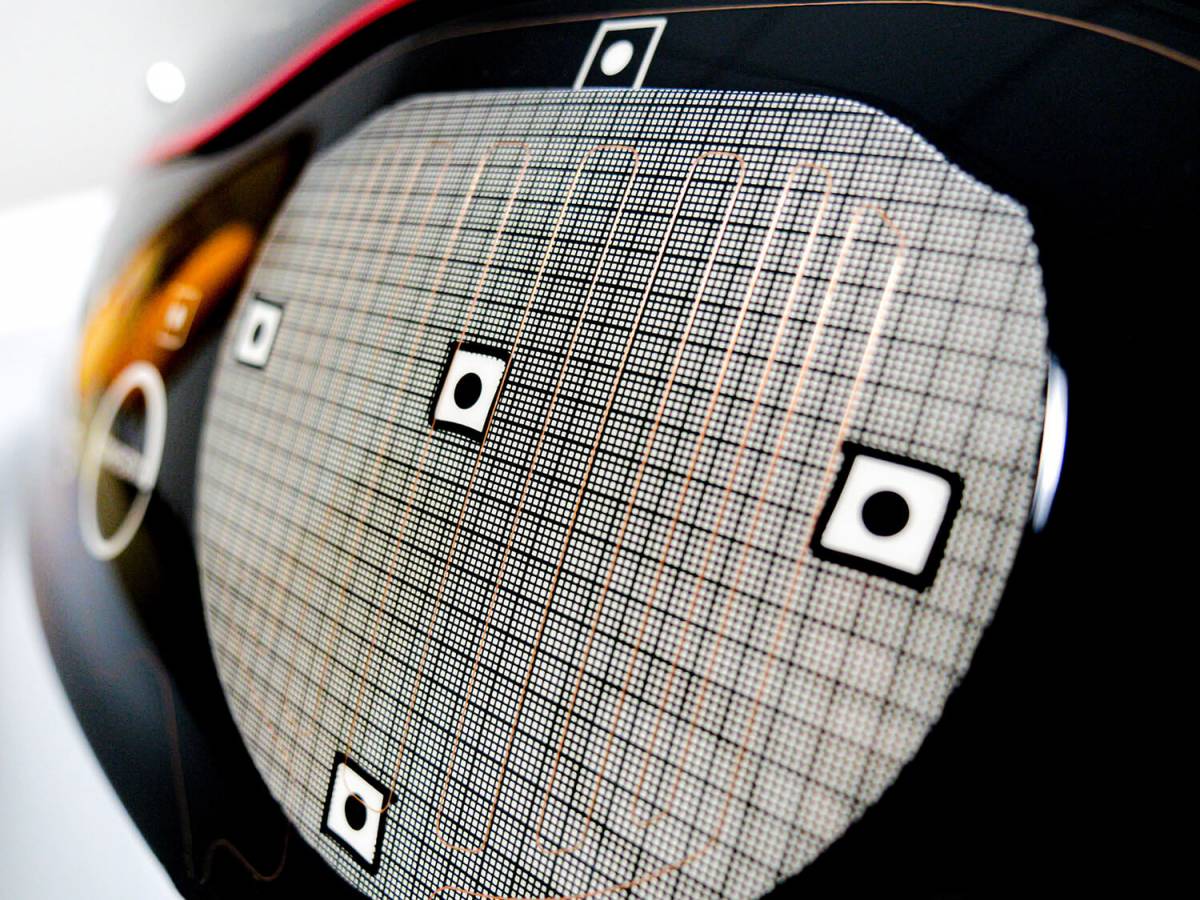

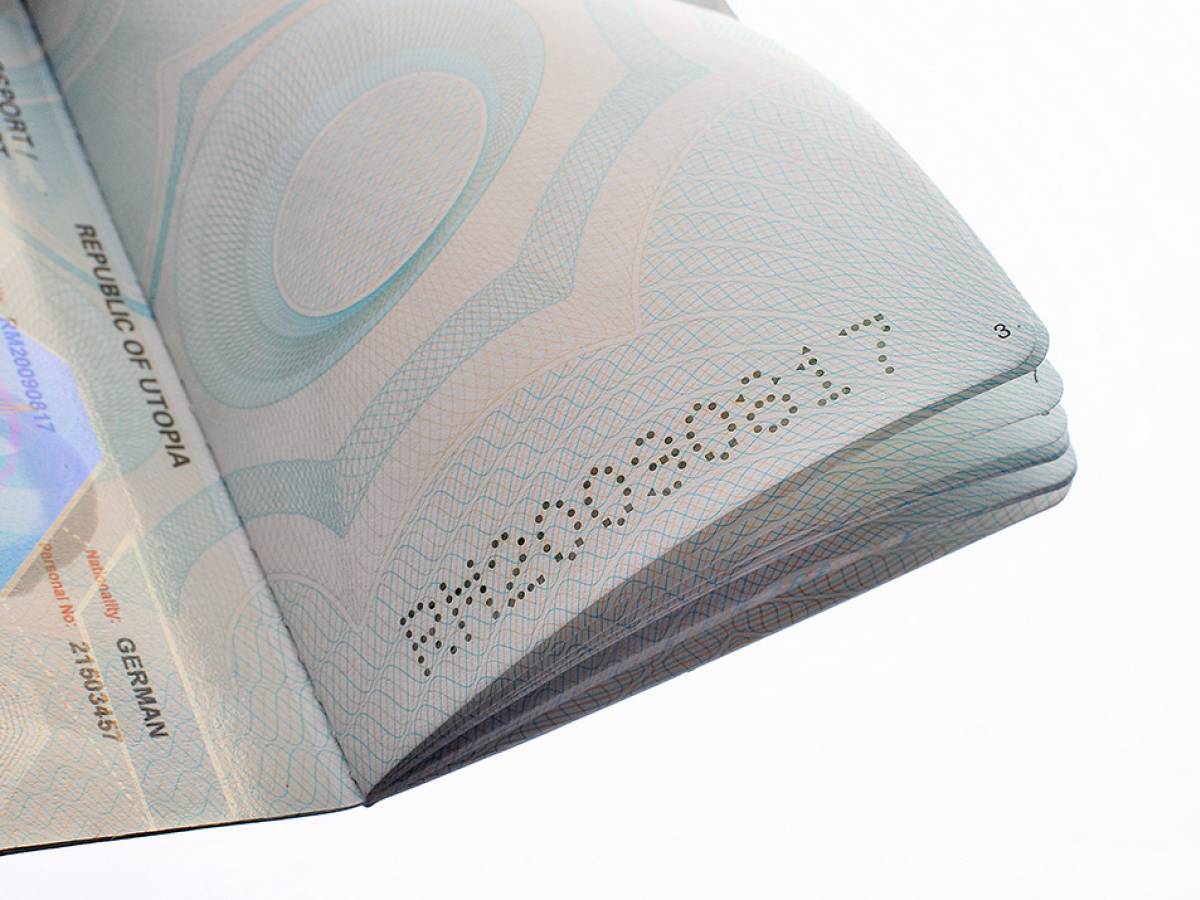

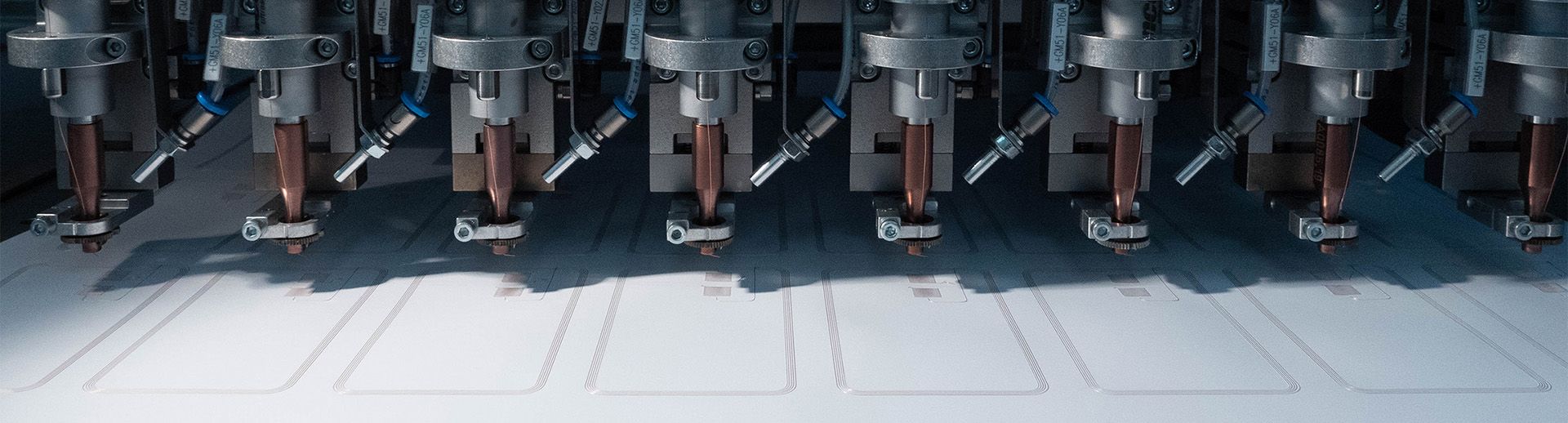

RFID inlays form the technological heart of modern ID documents - from electronic passports to contactless ID cards. Our ultrasonic wire embedding technology ensures the precise production of antennas with stable electrical properties and high mechanical resilience. Compared to etched or printed variants, wire-laid antennas offer an economically attractive and qualitatively convincing solution.

Our Solutions

at a Glance

- 4,050 antennas/hour

- 2,000 RFID inlays/hour

- Up to 12 patented wire embedding heads

- S2S, R2S, R2R

- "Easy Create" design software

- Any antenna geometry, including meander

- RFID inlays for ID1 and ID3 as well as customized layouts

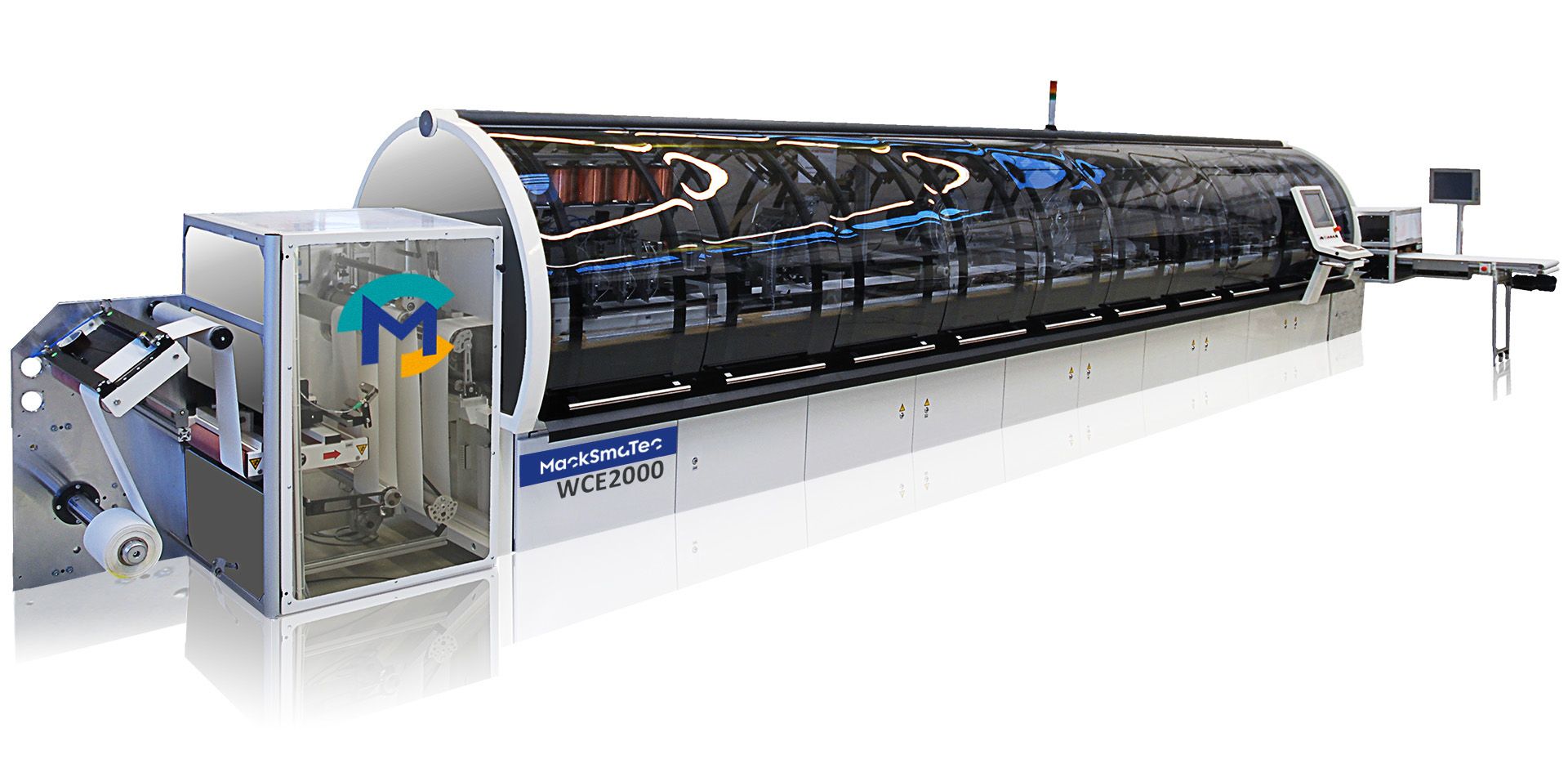

WCE2000 - Fully Automated RFID Inlay Production System

The WCE2000 sets new standards in the high-speed production of RFID inlays. With a throughput of up to 4,050 antennas per hour as a wire-laying machine and up to 2,000 complete RFID inlays per hour as an inlay production line, it offers maximum efficiency.

The flexible platform enables sheet-to-sheet (S2S), roll-to-sheet (R2S) or roll-to-roll (R2R) processing. Integrated functions such as module loading, laser marking stations and the embedding of transponders in various form factors enable customized production processes.

The WCE2000 is also compatible with ID1, ID3 and customer-specific layouts. It supports an efficient material flow with automatic web tension control, minimal waste and short changeover times - ideal for high production volumes and frequently changing product variants. Applications for the system include the production of electronic passports, health cards, access control systems and contactless payment methods.

- 1,800 antennas/hour

- Up to 8 patented wire embedding heads

- Rotary table concept

- "Easy Create" design software

- Any antenna geometry, including meander

- RFID inlays for ID1 and ID3 as well as customized layouts

WCE700 - Semi-Automatic RFID Inlay Production System

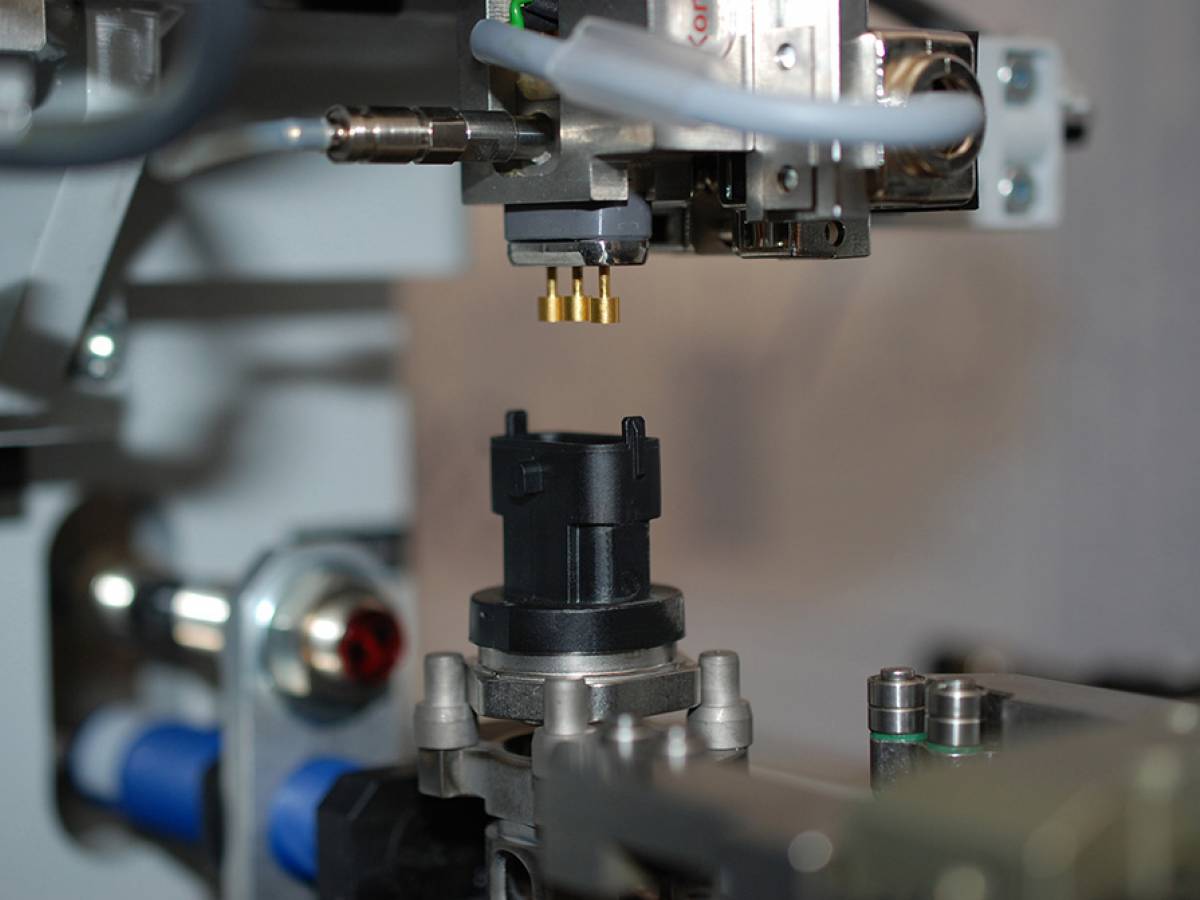

The WCE700 is an economical, semi-automatic system for the production of RFID inlays for ID documents in the standard formats ID1 (e.g. bank cards) and ID3 (e.g. passports). The system is based on a rotary table concept with four stations and manual loading and unloading.

It is suitable for both small orders and series production with a throughput of up to 1,800 antennas per hour. The machine combines precise wire embedding, module implantation, soldering and TC bonding in one compact solution.

- Up to 40 inlay sheets/hour

- Up to 2 patented wire embedding heads

- "Easy Create" design software

- Prototypes and small orders

- Any antenna geometry, including meander

- RFID inlays for ID1 and ID3 as well as customized layouts

WCE150 - Laboratory System for Prototypes and Small Series

The WCE150 is a practical laboratory solution for the production of prototypes and small orders with up to 40 inlay sheets per hour. With its single, flexible station and manual loading and unloading, it is ideal for the production of RFID inlays in ID1 and ID3 formats.

Alternatively, it can be used exclusively for the production of wire-laid antennas. The integrated functions such as module punching, pick & place systems and thermocompression welding or soldering can be individually combined.

Advantages of Our

RFID Inlay Systems

All systems in the WCE series – WCE2000, WCE700 and WCE150 – are based on a common technological foundation and therefore offer a variety of advantages for a wide range of production requirements:

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

Sales Card & Passport Systems +49 36925 929-322 Get in Contact now

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.