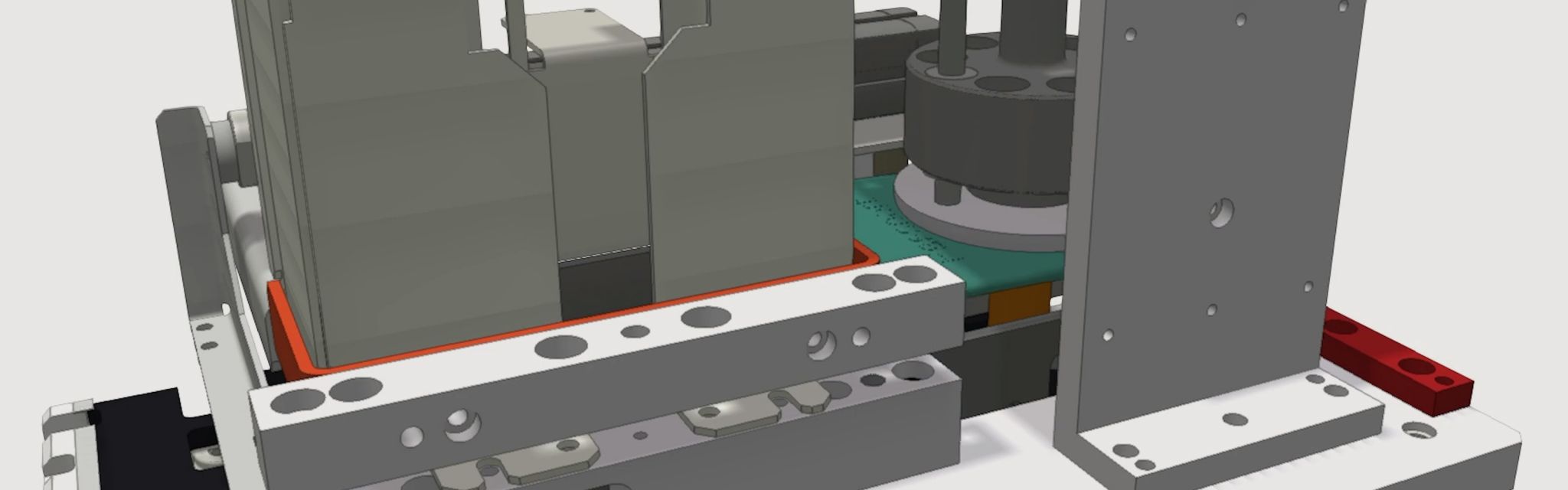

Your System, Digitally Mirrored.

For More Transparency,

Control and Performance.

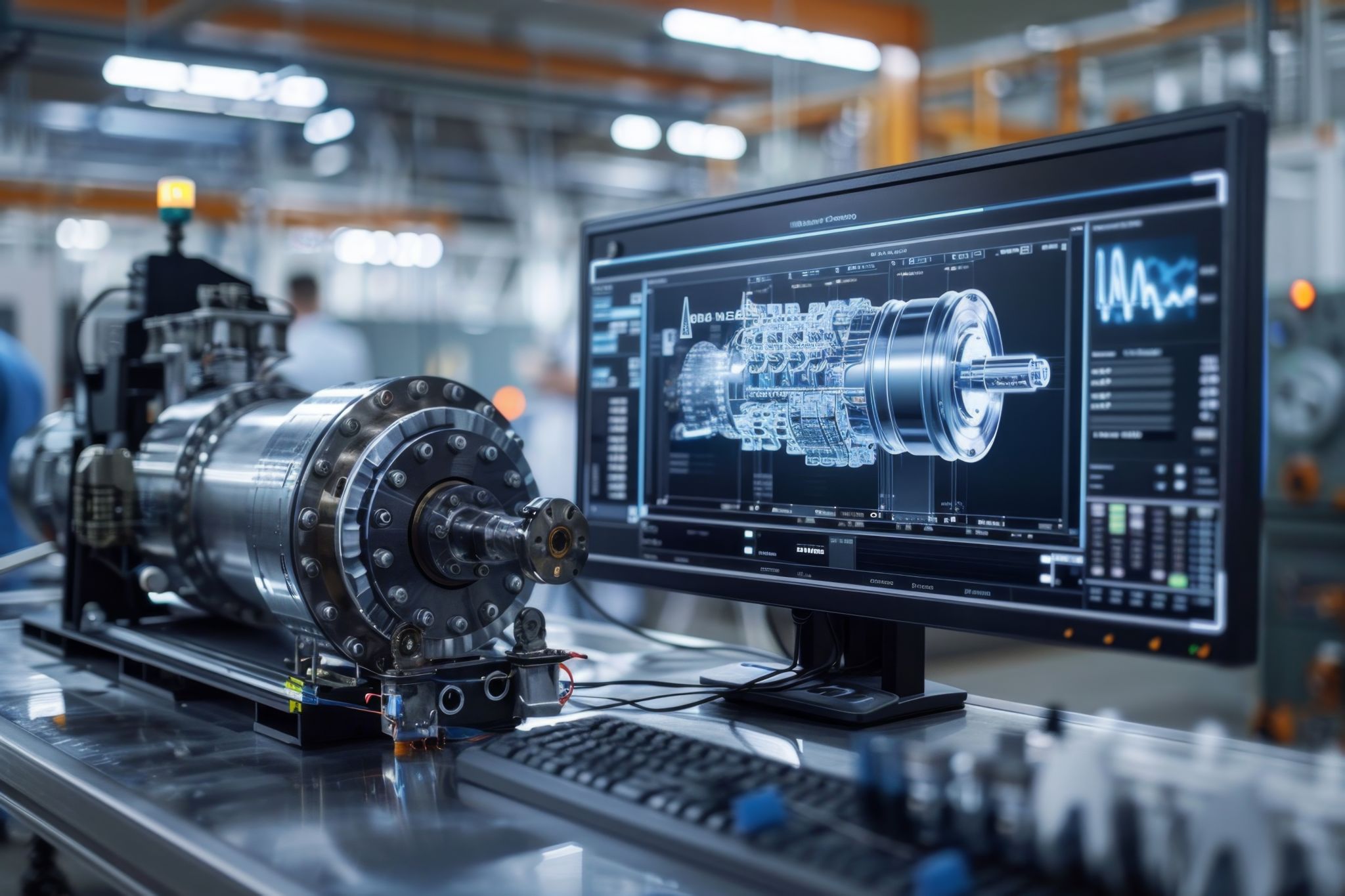

With our digital twins, you can create a virtual, data-supported, adaptive and real-time updated representation of your real system. This gives you precise insights into the condition, performance and process behavior at all times, from the first test run to the last year of operation.

Our solutions for your digital twin combine virtual commissioning, simulation and process optimization – for shorter project runtimes, reliable system tests and continuous efficiency improvements during operation.

With the help of sensor technology, data analytics and machine learning, the digital twin accompanies your system throughout its entire life cycle. It identifies optimization potential, predicts maintenance requirements and supports well-founded decisions for long-term economical production with maximum availability.

-

- /

Our Solutions

at a Glance

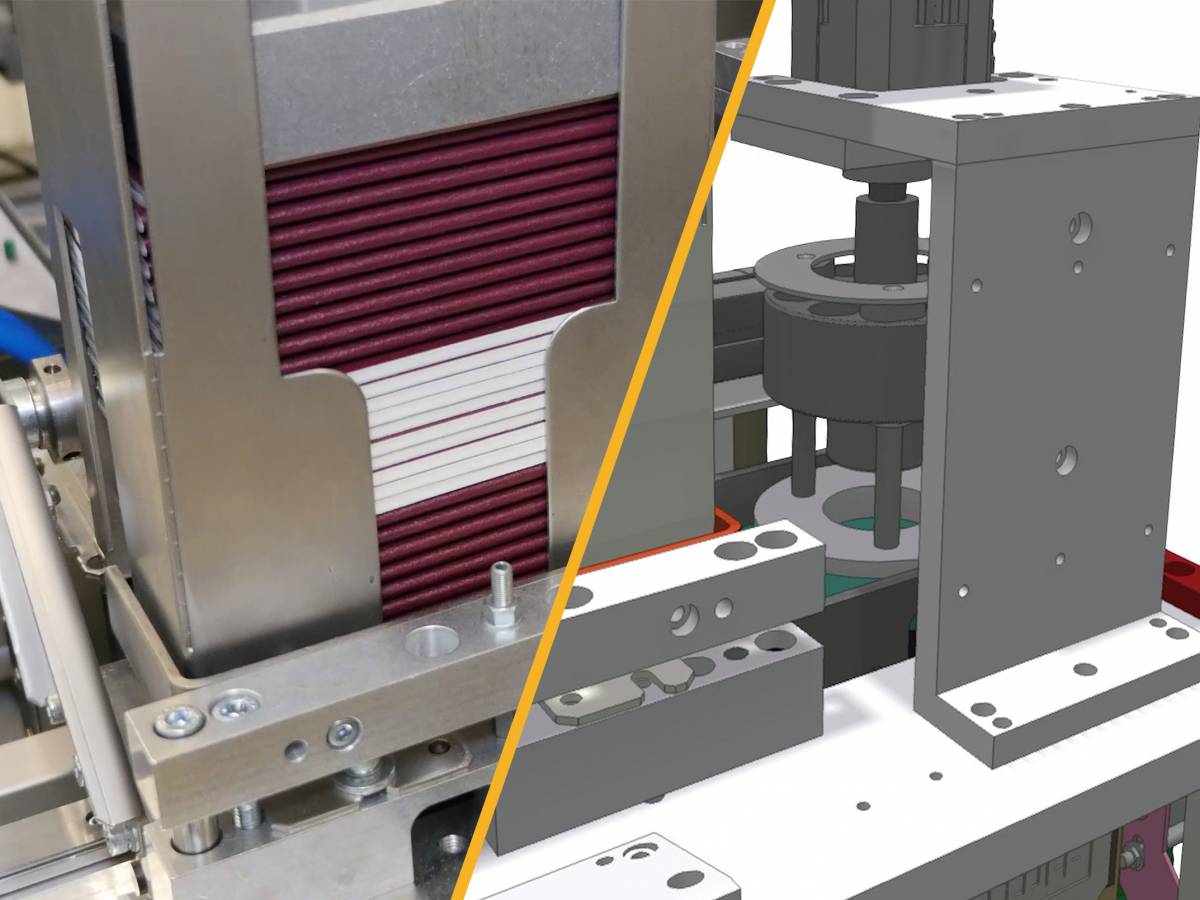

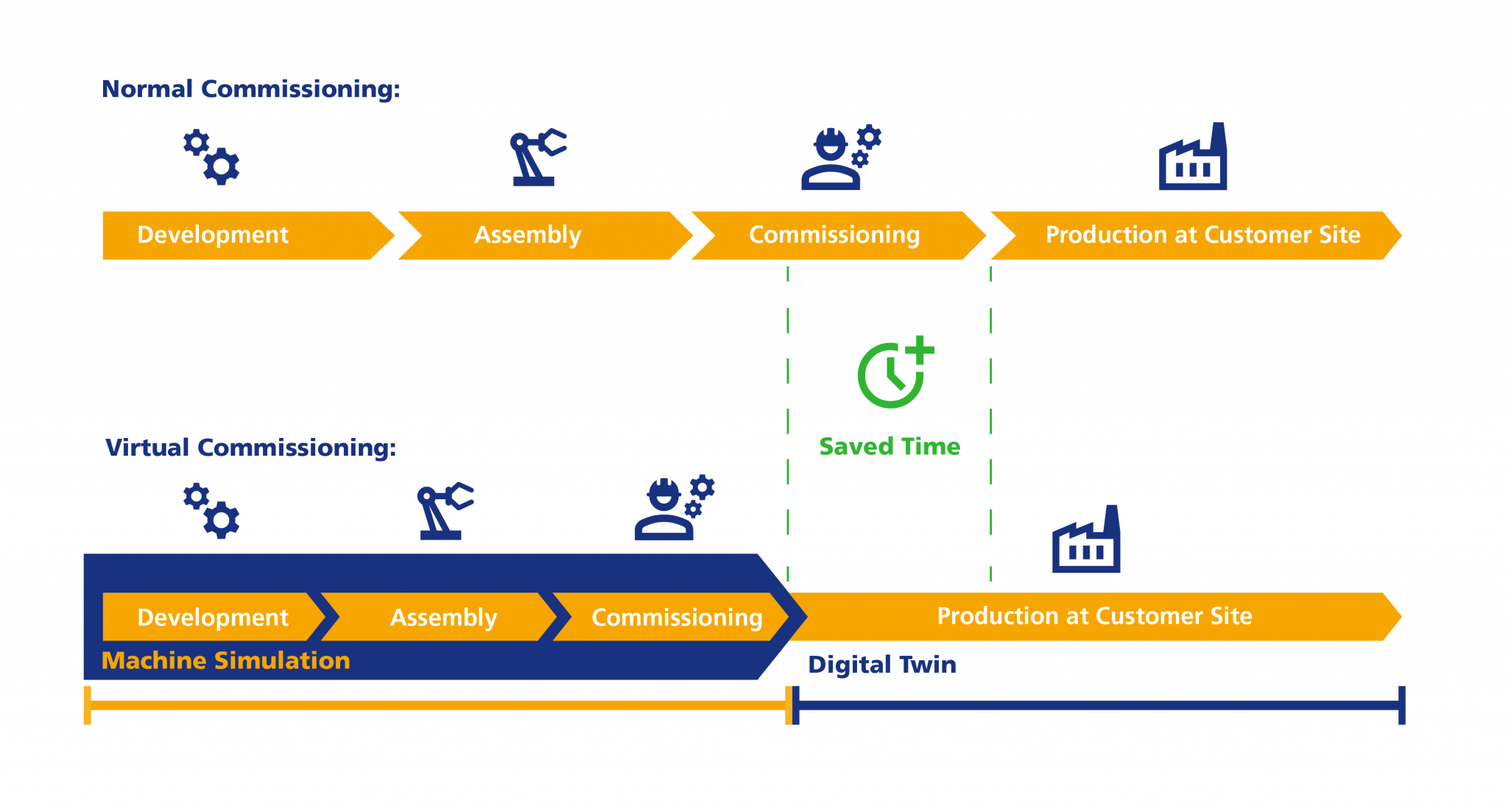

Virtual Commissioning

Plan More Efficiently, Start more Safely

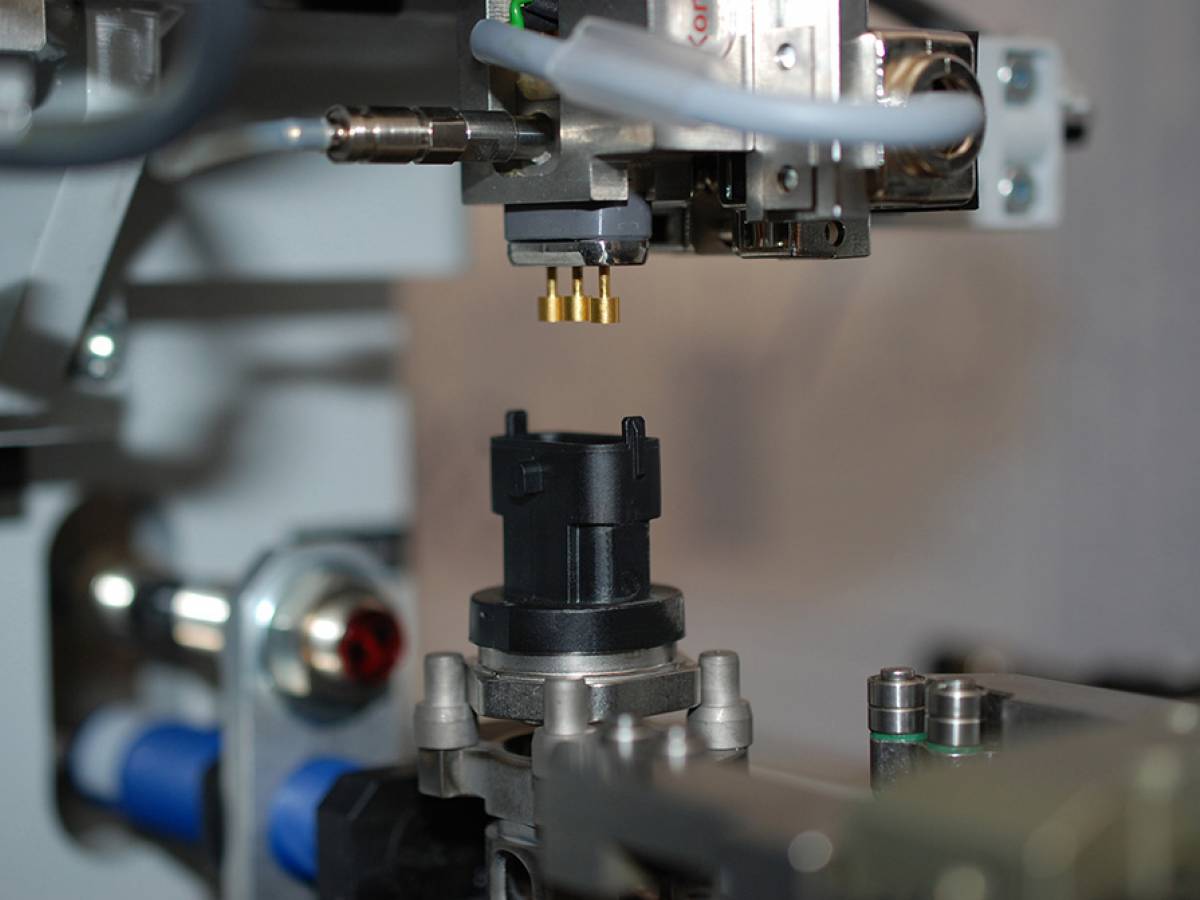

With virtual commissioning, you can shorten project lead times, reduce risks and ensure the performance of your machine before it physically exists. In a realistic simulation environment, control systems, interfaces and process logic can be comprehensively tested, validated and adapted without interfering with real production processes. Our engineers configure, parameterize and test your systems completely digitally, including software tests, process simulation and process optimization.

For you, this means

Time savings: Faster commissioning thanks to digital pre-tests, fewer delays on site

Risk reduction: early error detection prevents expensive rework and unexpected collisions

Flexibility & scaling: process changes can be easily integrated even in late development phases

Targeted training: Your teams train realistically, without running machines or prototypes

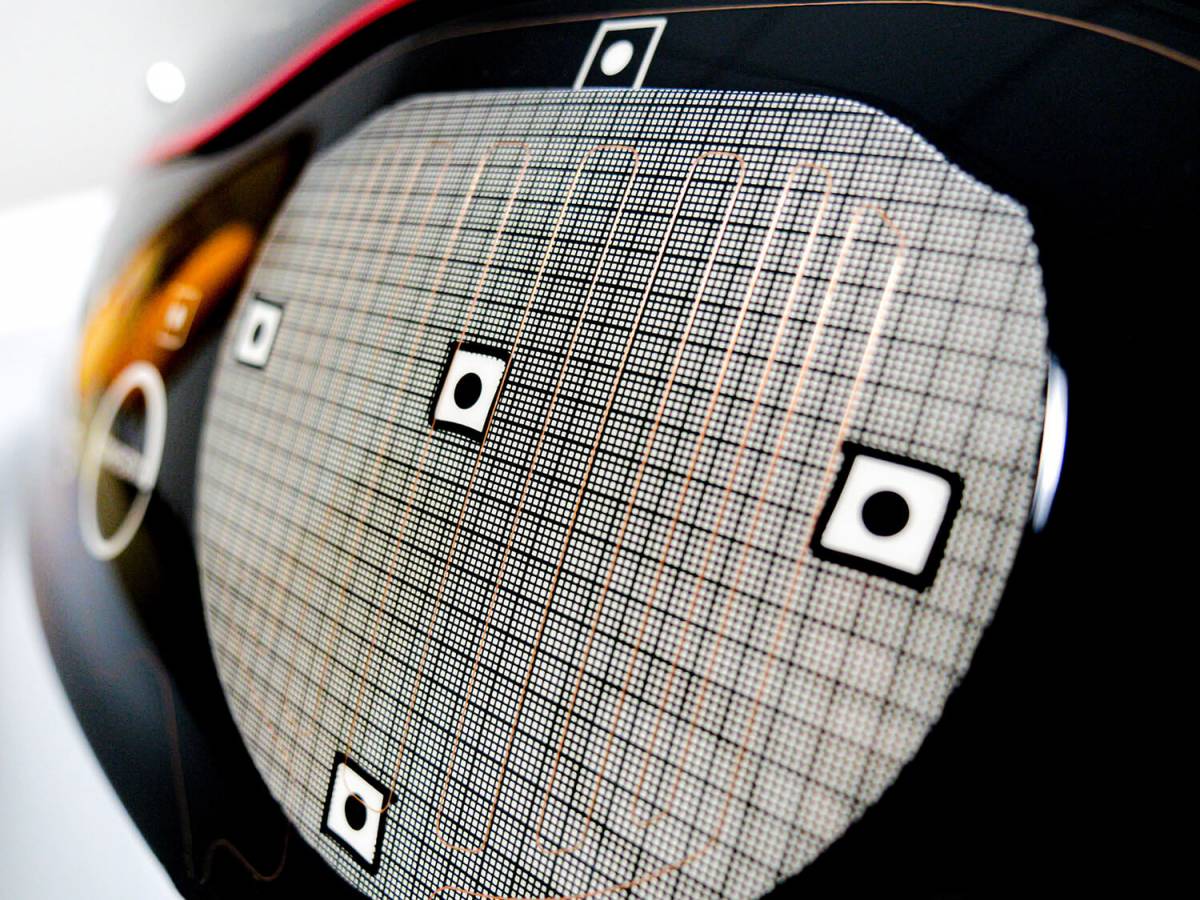

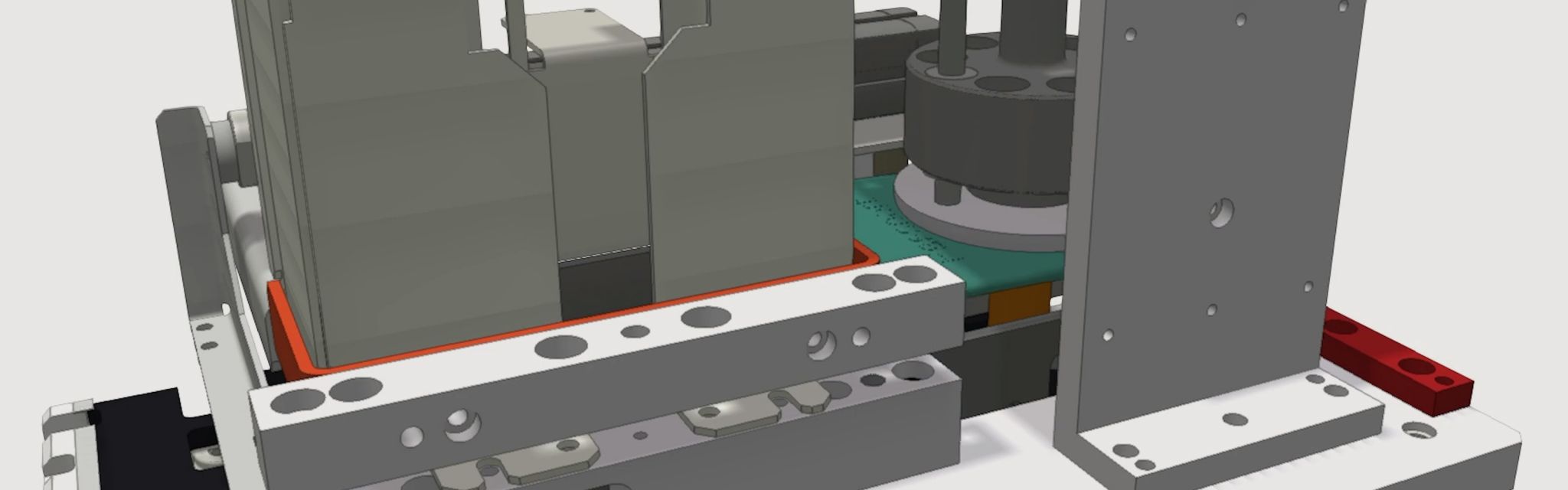

Simulation & Optimization

Planning Reliability Digitally Anticipated

With virtual simulations based on the digital twin, you can analyse and improve your production processes from the initial concept idea through to optimization during operation. The exact replication of your machine and system environment means that complex processes, conversions or expansions can be fully digitally validated. Changes to hardware and software can be tested in advance, process scenarios can be run through and the effects on performance and material flow can be evaluated

You can rely on this with our simulation solution:

Strategic planning security: early evaluation of process ideas before real costs arise

Investment protection: changes are checked digitally, risks and bad investments are significantly reduced

Accelerated implementation: Shorter project runtimes thanks to virtual pre-tests and optimized commissioning

Greater enthusiasm for innovation: new technologies can be simulated and integrated step by step without risk

More transparency: the use of materials, energy and resources can be planned precisely

Your Advantages

at a Glance

Interested in a

customized solution?

Our experts will be happy to advise you on suitable systems and support you in implementing efficient production processes.

Pioneering Technologies

for Modern Challenges

Innovative technologies from MackSmaTec enrich manufacturing processes all over the world.

Find out how you too can benefit from our state-of-the-art processes.