Mechanical Engineering Wiki / Chaku-Chaku

Chaku-Chaku - Work organization model for increasing productivity

Chaku-Chaku is a work organization model whose name was taken from Japanese and can be literally translated as "load, load" in German. Alternatively, the term "flow principle" is often used in this country. In industry, work organization models such as the chaku-chaku line aim to achieve greater standardization and improved process control. In the long term, this should result in an increase in productivity in combination with an increase in the profit margin. Chaku-chaku can be understood as an extension or further development of the one-piece flow model .

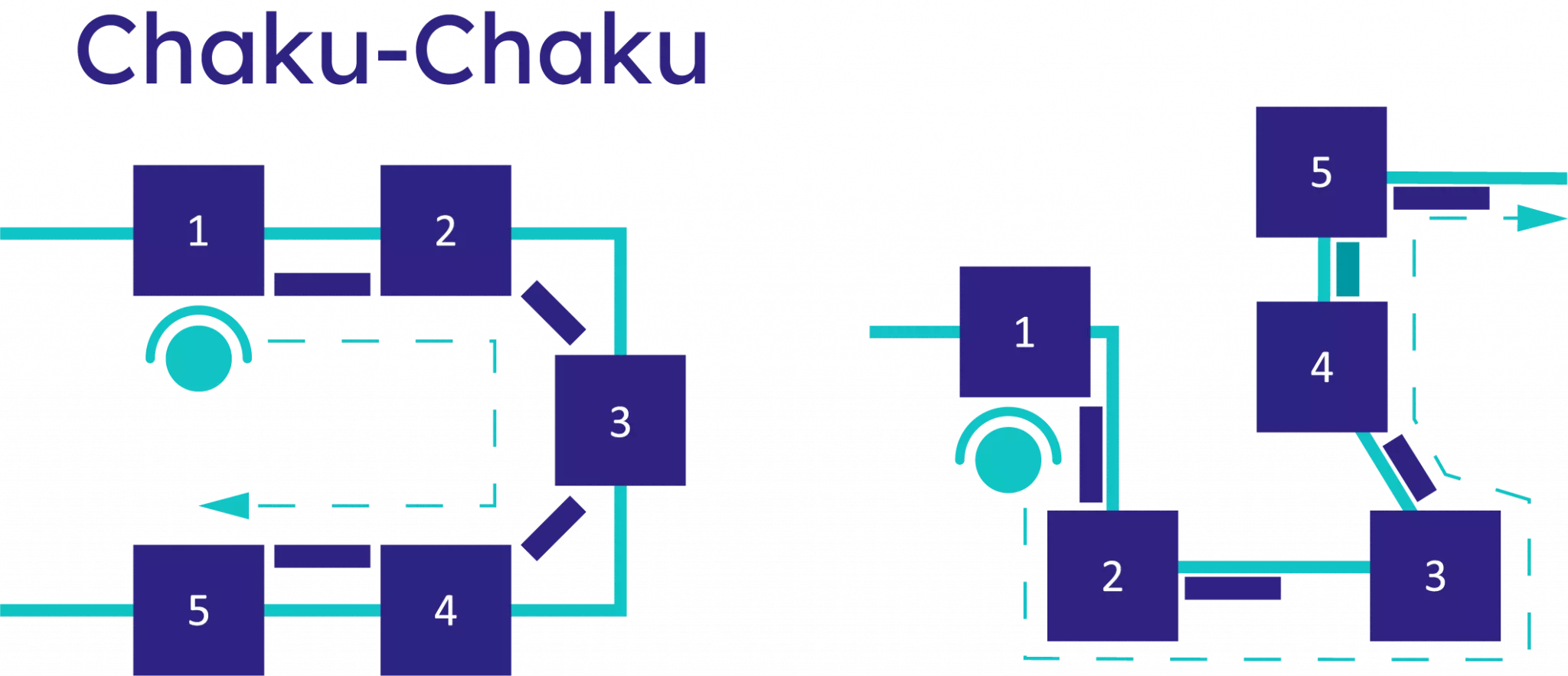

Chaku-Chaku is a model of flow and series production in which all workstations required for the manufacture of a product are set up in such a way that the distances between them are minimized. This often results in an arrangement of workstations that is reminiscent of a U or an omega in terms of shape. This arrangement makes it possible for a single employee to operate several machines or workstations simultaneously or in parallel, usually only being responsible for loading and unloading the respective machines and transporting the products from one station to the next. The machine itself performs its task without the intervention of the employee. Depending on the complexity, it is also possible to equip a chaku-chaku line with several employees who are each assigned individual tasks. In practice, chaku-chaku models with one to three workers have proven to be successful.

What are the potential advantages of chaku-chaku?

By eliminating long transport routes between individual work stations, time losses in the manufacture of a product are minimized. At the same time, expensive and complex interlinking machines become obsolete. Not only do these no longer have to be purchased, they can even be dismantled in some circumstances. Depending on the product, manual workstations can also be integrated within the Chaku-Chaku line. As the loading and starting of the individual machines at the respective work stations is carried out by the employee(s), machines working at different speeds or slower speeds can be coordinated with each other. This leads to improved time coordination without undesirable losses. In this case, however, it must be taken into account that stations for the intermediate storage of partially finished products must be set up within the chaku-chaku line.

Another advantage of chaku-chaku is the shorter training period for the employees involved in the flow work, who generally only have to cope with a few complex tasks and only have to take care of loading and unloading the machines. There is no need for time-consuming training or the employment of skilled workers. This also saves costs in the long term.

What are the potential disadvantages of Chaku-Chaku?

Some of the advantages of chaku-chaku mentioned above can also be cited as points of criticism from a specific point of view. One of these is the monotony of the work required of the employee, which can lead to highly one-sided stress and corresponding health disadvantages. As working hours are also accelerated in the chaku-chaku line, stress and physical strain are added to this.

At the same time, the absence of trained specialists can also be seen as problematic in the long term. Employees who work in a chaku-chaku line are often trained within a very short period of time and generally do not require any specific training for their work. From the employee's point of view, this is a cause for concern because the wage level falls and it is difficult to increase wages. From a wage perspective, additional qualifications have practically no effect on the individual's intended activity within the chaku-chaku line. This is precisely why trade unions and works councils often oppose the implementation of the chaku-chaku model.