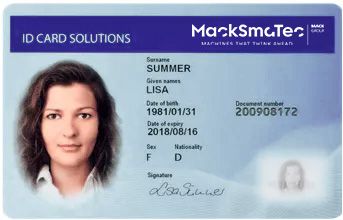

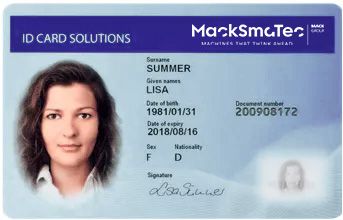

We have them in our hands every day. We use them to identify ourselves and make purchases. They make our everyday lives more efficient and it is hard to imagine today's information society without them. Bank and SIM cards, driving licenses, ID cards for customers, employees or swimming pool visitors - in many areas today, ID cards or so-called smart cards enable us to manage personalized data.

Printed photos, graphics or inscriptions are used to create optical identification features. If a card is used for data transmission, then digital information is available for readers and thus entire networks thanks to built-in chips and RFID inlays. The elements mentioned can be freely combined and thus become purpose-oriented solutions with individual configurations. The personalized card organizes various accounts and credit balances, grants access authorizations or allows people to be uniquely identified. They can also be equipped with special security standards. In practice, passport photos, watermarks, barcodes or digital security keys have proven themselves for personalizing cards.

Diversity: requirements for the personalized card

The requirements that these cards need to meet depend heavily on the area of application, the number of cards to be produced and the required security features.

In general, however, a good feel, reliable functionality and high resolution and color fidelity in printing are essential. In addition to ecological aspects such as good environmental compatibility and sustainability with regard to the production process and choice of materials, the durability of the information carrier is also becoming increasingly important. Accordingly, environmentally friendly, solvent-free printing methods and more resistant card material are preferred in practice. Reliable, simple processes that can be used flexibly in practice are required. Depending on the required function, the built-in security features and the number of cards to be produced, the aim is to produce such cards in an economically viable way. High-resolution, high-performance printing methods are required to generate largely forgery-proof, unique optical features such as photos or fingerprints.

Printing processes: their credentials and differences

In the first printing techniques, ink was applied to the surface by "printing".

Specially produced printing plates are required for each job, which is why this method is only used economically for very large print runs, mainly on paper. Although this method produces high-quality prints, it lacks the ability to implement variable data.

Inkjet technology is a further development and alternative to the conventional process. Alongside laser technology for engraving, it is the most commonly used non-contact printing technology and is used in many home and office printers. Using variable data, inkjet produces high-resolution print images without printing plates and with few moving parts on countless surfaces.

Less wear and tear makes machines low-maintenance.

They enable

less downtime

Smooth work processes with print-on-demand

cost-effective production, even of small quantities.

Depending on the field of application, inkjet enables the printing of a wide variety of surfaces with a wide variety of materials. For graphic applications, for example, different types of ink and solvents are used, which have different properties depending on the application (e.g. UV-curing).

Depending on the functionality, completely different materials can also be used for printing. In semiconductor technology, special material combinations enable OLED screens for tablets or smartphones.

In the food sector, on the other hand, they are used to implement hygienic processes for the production of edible end products. Food colors are used, for example, for the illustration of a wedding cake or an ice cream cone.

Continuous inkjet (CIJ) and drop-on-demand (DOD) are mainly used. A few picolitre-sized (1 pl = 10-12 l) drops are sprayed onto the surface. They are far smaller than drops of water (approx. 5*10-5 l).

Continuous inkjet (CIJ)

With CIJ, a continuous stream of ink is pumped from a reservoir into one or more spray nozzles.

In the nozzles, piezoelectrically controlled and high-frequency droplets are released, which are hydrostatically charged with electrodes and precisely deflected by a current-controlled electric field to produce the desired print images. Droplets that are not required and not intended for the image are collected and fed back into the cycle.

Due to the high printing speeds, the various inks used usually dry with the help of solvents.

A certain mixing ratio with an even process supply must be ensured at all times.

This results in longer warm-up phases and more complex logistics, which is why the process is used almost exclusively by industry, including for labeling products and packaging. The method allows fast printing with moderate image quality.

Drop-on-demand (DOD)

In contrast to CIJ, DOD is a technique in which certain drops are formed and emitted only when required, rather than continuously. Ink does not have to be collected or recycled.

The print head contains many, in industrial applications thousands, of small chambers. Ink is fed into the openings, while a finely adjusted vacuum prevents leakage.

Differently generated pressure pulses release the required drops from the respective capillaries.

In thermal nozzles, part of the solvent-ink mixture evaporates through the application of heat. In piezoelectric nozzles, overpressure pulses are generated by voltage-controlled short-term expansion of crystals.

After the pulse, the remaining ink withdraws and the capillaries are refilled by the tank.

Other sophisticated technologies also influence the size and speed of the droplets. A clever arrangement and overlapping of drops of different sizes, consisting of basic colors, creates color-intensive, detailed prints. Various types of ink are used. They are based on solvents or water. For food packaging, electromagnetic or UV radiation is often used, which dries out the ink almost completely and leaves no volatile components behind. This generally requires inks that are as strongly set as possible and no longer contain any solvents or other free components. To achieve this, UV or electron beam curing inks are used, for example, which consist of various molecules with functional groups that determine the binding properties of the ink. The printing process can therefore be used for the aforementioned printing requirements where no migration of the ink components is permitted (e.g. food packaging).

DOD is particularly suitable for high-resolution, sophisticated imaging based on variable digital data. The method is even used in 3D printing and nanotechnology.

Conclusion

Handy plastic cards enable cost-effective automated card personalization in many areas.

Depending on the quantity to be produced, they can be imaged and managed autonomously or externally. Special security standards can be created and verified using digital or analog unique selling points, while electronic components enable data transfer using various freely combinable technologies. The DOD process prints these cards in a reliable and future-oriented way and enables fast and high-quality personalization of cards.

Find out more about our card personalization products here