Contract manufacturing refers to the outsourcing of manufacturing processes to external companies. This is particularly worthwhile for manufacturing processes that require highly complex technologies or specialist knowledge. Contract manufacturing offers many advantages and is being used by more and more industries to manufacture products faster and more cost-effectively. How contract manufacturing works, what advantages it promises and why it is particularly attractive in Germany is explained below.

What is contract manufacturing?

Contract manufacturing refers to a process in which companies outsource individual manufacturing processes to external service providers. Alternatively, this process is also known as contract manufacturing or external manufacturing. The term "extended workbench" is equally common. Contract manufacturing can take place in Germany, but orders are often placed with (supposedly) cheaper contract manufacturers abroad.

How does contract manufacturing work?

The principle of contract manufacturing is quickly explained using an example: an automotive supplier requires CNC-machined components, but has neither a CNC machine nor appropriately trained specialists. The company therefore decides to outsource the CNC machining to a contract manufacturer. It provides all the technical details for CNC machining as well as scheduling and financial specifications. The subcontractor then begins machining, with a contractual relationship existing only between the automotive supplier and the subcontractor. It is deemed to be concluded as soon as the production of the CNC-machined components has been completed.

Which industries use contract manufacturing?

Outsourcing individual production processes from your own company can be advantageous because it saves time and money. This is why contract manufacturing is paying off for more and more industries. Typical examples in which contract manufacturing is now standard:

Automotive

Electrical industry

Aerospace

Mechanical and plant engineering

medical technology

CNC technology is often used in contract manufacturing. CNC (Computerized Numerical Control) refers to machine tools that can produce or process workpieces fully automatically with outstanding precision and speed. CNC milling in particular is in demand in the contract manufacturing sector. Companies can also use external machining in the following areas:

What advantages does contract manufacturing offer?

Outsourcing individual production processes can give companies a decisive competitive advantage. It is particularly worthwhile for the following reasons:

Advantage 1: Cost savings

The purchase of a CNC machine incurs high costs. Added to this are the salaries and training costs for skilled workers who know how to use the technology. The investment only pays off if the machine is fully utilized. For many companies, this is not the case and they can save time and money by outsourcing the relevant machining processes to a contract manufacturer.

This also applies to production facilities: in order to take over highly specialized production processes yourself, the spatial capacities - for example for setting up a CNC machining center - must be available. If this capacity has to be created first, this results in additional costs that can be saved thanks to contract manufacturing.

Advantage 2: Cushion production peaks

Outsourcing part of the production to an external contract manufacturer can be particularly profitable if the order situation exceeds the company's own capacities. Instead of investing in a costly expansion of the company, the production peaks are cushioned by the contract manufacturer. This allows greater room for manoeuvre while at the same time shortening delivery times and increasing production output.

Advantage 3: Benefit from quality advantages

Contract manufacturers are usually specialists in their field. They not only impress with their flexibility, but also with their special expertise, which guarantees above-average production quality. This ensures an even better cost-benefit balance - partly because expensive reworking is avoided.

Is contract manufacturing abroad worthwhile?

Many external manufacturers offer their services from abroad. Wage levels are often lower there, which means that contract manufacturing can be carried out at lower costs. Typical countries in which low-cost contract manufacturing is offered include Poland, the Czech Republic, China and Romania. Although contract manufacturing abroad promises advantages at first glance, a closer look reveals several disadvantages:

Disadvantages of contract manufacturing abroad

1. underqualification and poor quality of work

Many contract manufacturers based abroad do not employ well-trained skilled workers, but try to increase their profits by using under-qualified lateral entrants and unskilled labor. In many cases, this also explains the significantly lower production costs compared to Germany. In addition to technical qualifications, these are often at the expense of occupational safety and employee rights. Furthermore, the quality of work can suffer. This ultimately results in higher costs for the client from Germany because reworking becomes necessary or punctual delivery cannot be guaranteed.

2. outdated machines

In economically weaker countries in particular, contract manufacturers rarely invest in the latest generation of technology. Work is then often carried out on outdated machines, which can have a negative impact on quality and speed.

3. high transportation costs

Transport costs are a factor that must always be taken into account in contract manufacturing. Compared to an external processor from Germany, however, most providers based abroad incur significantly higher transport costs because the distances to be covered are longer. Complications can also arise due to exchange rates.

Important: Quality control is an important aspect of external processing. While regular inspections are still easy to implement for contract manufacturing in Germany, this aspect becomes more complicated when outsourcing abroad. Additional costs may arise.

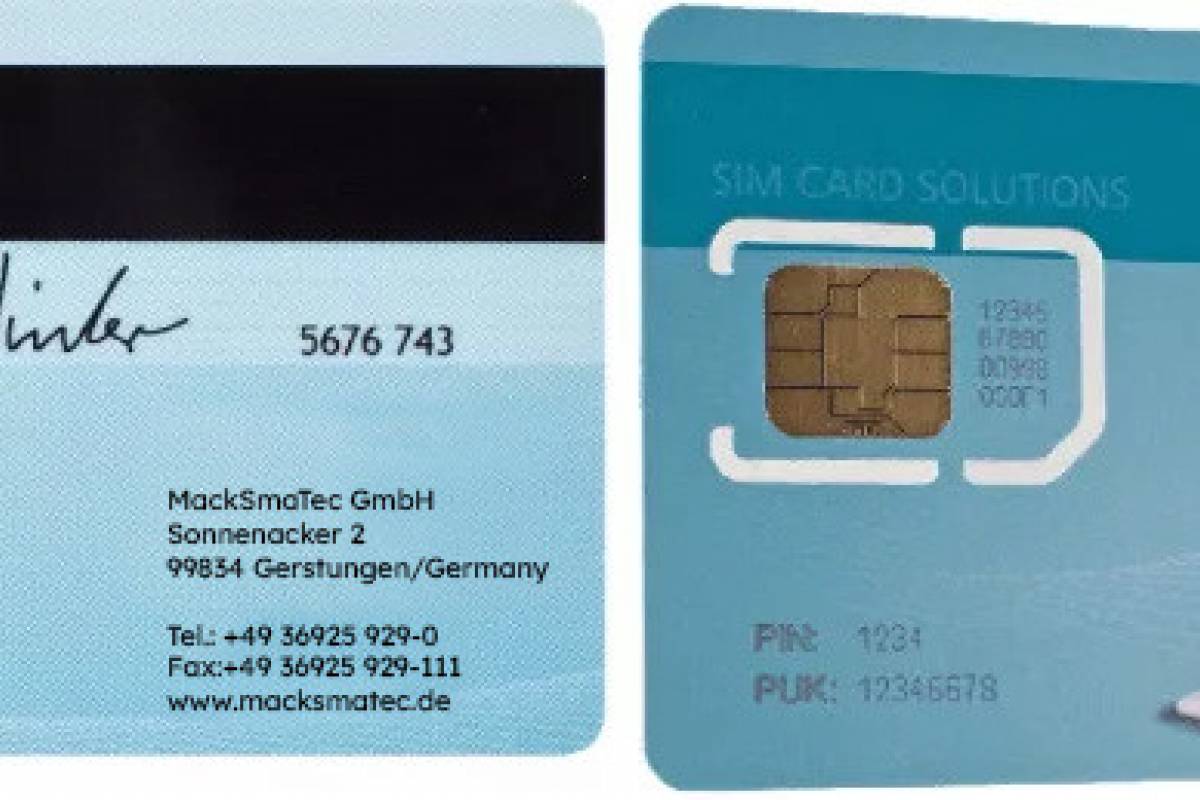

Contract manufacturing at MackSmaTec: speed, efficiency and quality

As a contract manufacturer, we have been reliably supporting our customers for many years. You benefit from our comprehensive expertise, particularly in the field of CNC contract manufacturing. Whether turning, milling, grinding, eroding or measuring 3D coordinates: Thanks to the latest technologies and the many years of experience of our highly trained specialists, we offer you quality and precision at every step of the process. We are also happy to work for you at short notice to reliably cushion production peaks.

As a contract manufacturer, we can also support you with sheet metal processing, surface finishing or assembly production. Simply contact us directly and we will be happy to deal with your request promptly and personally.