Mechanical Engineering Wiki / Crimping

What is crimping?

Crimping is a joining process and is often used as an alternative to soldering or welding. Crimping is preferably used when it comes to making electrical connections. An example of this is the attachment of a plug to a cable, including the correct connection between the wires of the cable and the plug contacts. The main advantage over soldering and welding processes is speed and precision. As a result, crimping has now become widely accepted in large-scale serial production.

How does crimping work?

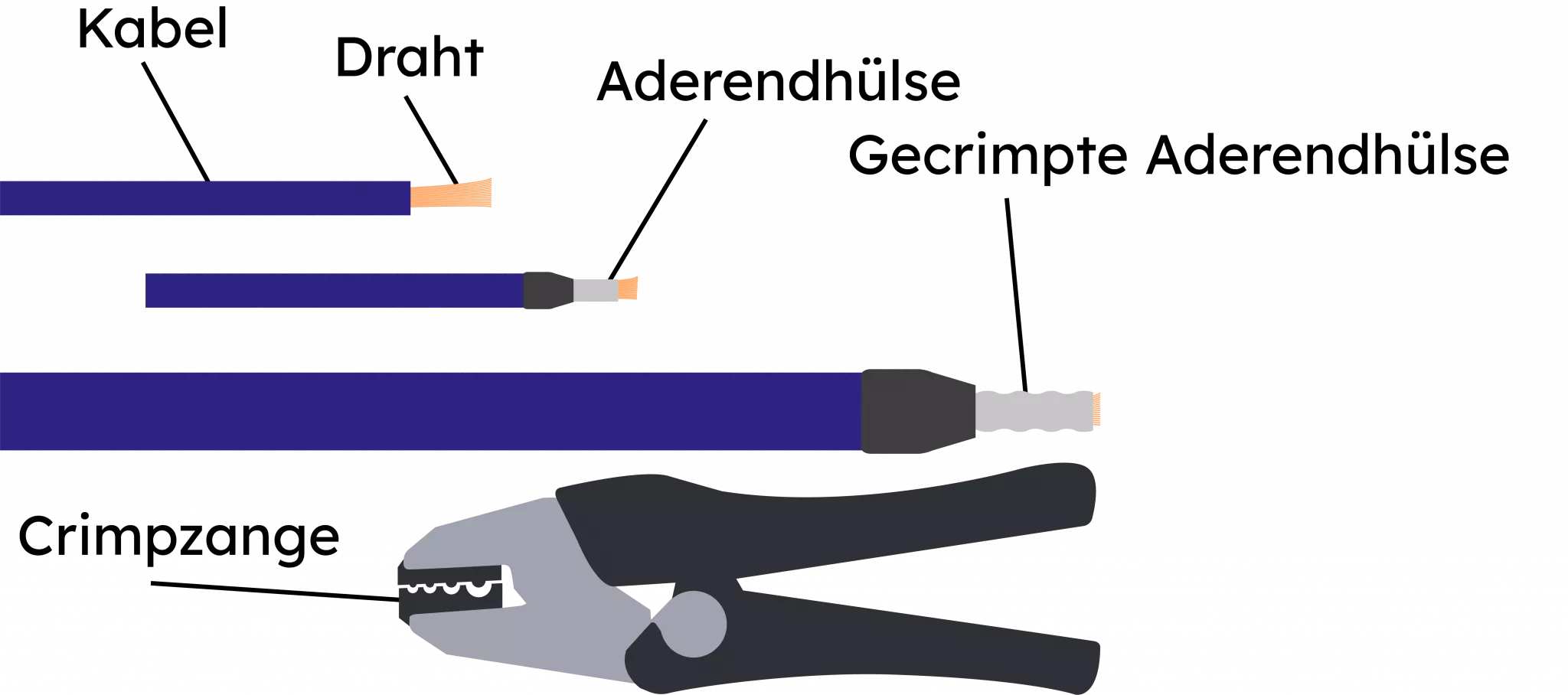

The functional principle of crimping is relatively simple: pressure is applied to two components to create a plastic deformation between them, which connects the two components together. Special tools are used for this, such as crimping pliers, and the two components are pressed into each other. The connection created during crimping is stable and permanent. In industrial production, crimping presses or automatic cable assembly machines are usually used for crimping. So-called crimping dies are crucial for precise work. These are matched to the components to be connected and have a decisive influence on the type of deformation or crimp connection. If the crimping die is not an exact fit, a permanently stable connection between the two components cannot be guaranteed.

Where is crimping used?

Crimping is not only used in the production of electrical connections, but is also known from more everyday situations. For example, pasta specialties such as ravioli or Maultaschen are crimped. This joining process is also sometimes used in everyday office life, for example when the closing seal on a document is applied using a crimping process. In the industrial sector, HF electronics and telecommunications are increasingly relying on crimp connections. The main advantage of crimping here is that it makes it possible to lay pre-assembled cables without a connector. With the help of crimping, the connector is only attached after the cable has been laid.

What is important when crimping?

In order to create a permanently stable connection between two components during crimping, it is important that the crimping is carried out with sufficient force. Otherwise, the plastic deformation may only occur incompletely, resulting in weak points in the connection. If, on the other hand, too much force is applied, the components may be damaged. An inadequate or unsuitable crimping tool can also be a possible source of error: if the crimping die does not sit correctly on the components to be connected, this can result in faulty or insufficient crimping.

What are the advantages of crimping?

Crimping enables a fast, precise and stable connection between two components. This can be classified as homogeneous, gas-tight and electrically and mechanically safe - provided the crimping is carried out correctly.