Mechanical Engineering Wiki / Shrinking

Shrinking or shrink-fitting

Shrinking or shrink-fitting is a joining process based on the principle of thermal expansion. It is used particularly frequently in mechanical engineering and can be combined with other joining processes, such as cold expansion or expansion. Shrink-fitting creates seamless, durable joints that can withstand even the most extreme stresses. Accordingly, in many industrial sectors, shrinking is proving to be a worthwhile alternative to joining processes that involve material damage (e.g. soldering, screwing or welding).

How does shrinking or shrink-fitting work?

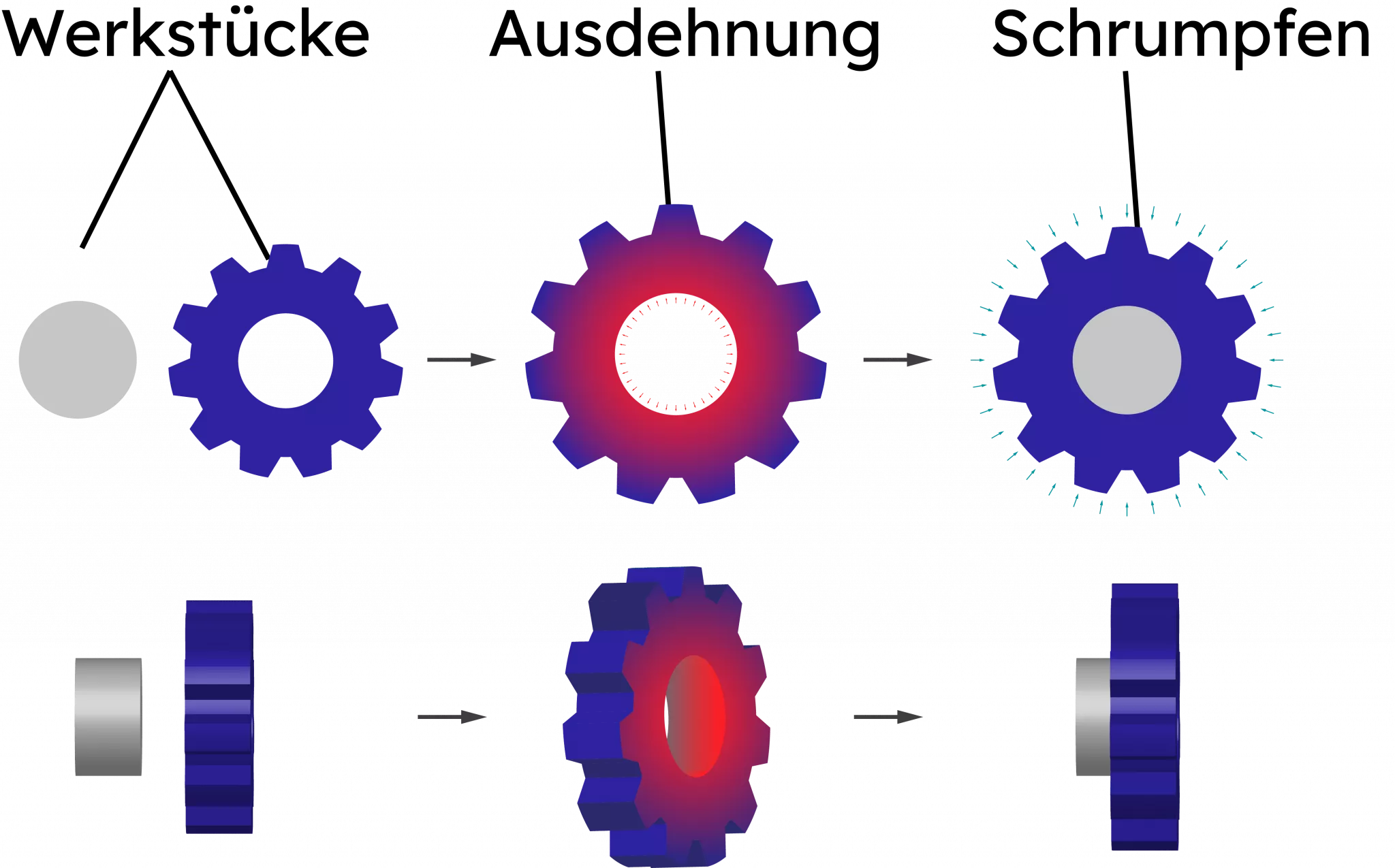

The industrial joining process of shrinking is based on a simple physical principle: certain materials expand at high temperatures and contract again when cold. In order to join two components together by shrinking, one of the two components is heated to the degree at which it expands. The expanded and heated component is then pulled over the unheated component and cooled. As the temperature drops, the previously heated component shrinks to its original size and encloses its joining partner permanently and firmly. This connection can only be released again when the component is reheated. It is important to note that only the outer, enclosing component is heated. If the enclosed component also expands, the shrink joint will not be released. This is usually achieved with the help of induction heating, as this can heat the components precisely and gently.

Where is shrink-fitting used?

Shrink-fitting is normally only used in conjunction with metal parts. As it must be ensured that the material properties remain stable at the same level after expansion and cooling, other materials are not suitable for shrinking. Shrink-fitting is often used to join rings, gears, shafts or pipes. In addition to mechanical engineering, special areas of application for this joining process can also be found in shipbuilding, the automotive industry and aerospace engineering. A classic example is the manufacture of railroad wheels, where the wheel tire and shaft are joined permanently and stably by shrink-fitting. Many tools are now also equipped with shrink-fitting technology: In this way, for example, attachments can be precisely fastened in the chuck.

What are the advantages and disadvantages of shrink-fitting?

Shrinking or shrink-fitting is a relatively simple joining process that does not require any additional aids such as adhesives. Furthermore, there is no material damage. The connection created during shrinking is stable and permanent, but can also be released by reheating the joining partner. However, the process is only suitable for metals that can expand when heated without losing any of their material properties. It is therefore essential to ensure that the correct temperatures are maintained when shrinking. Moreover, uniform heating is crucial to prevent different degrees of expansion and thus material distortion.