Mechanical engineering Wiki / Spiral conveyors

Spiral conveyors - an important component of conveyor systems

Spiral conveyors are an important component of conveyor systems in the industrial sector.Similar to linear or inclined conveyors , they can be integrated into a complex conveyor system or used as an independent component for the vertical conveying of different types of goods. In addition to conveying bulk goods, spiral conveyors are primarily used for sorting small piece goods such as screws or turned parts.As a rule, spiral conveyors are custom-made products that are specially designed for the respective application. As part of a sorting system, spiral conveyors can therefore only ever be used for precisely defined goods. With the help of conversion measures, however, spiral conveyors can be converted so that they can also sort similar components.

How does a spiral conveyor work?

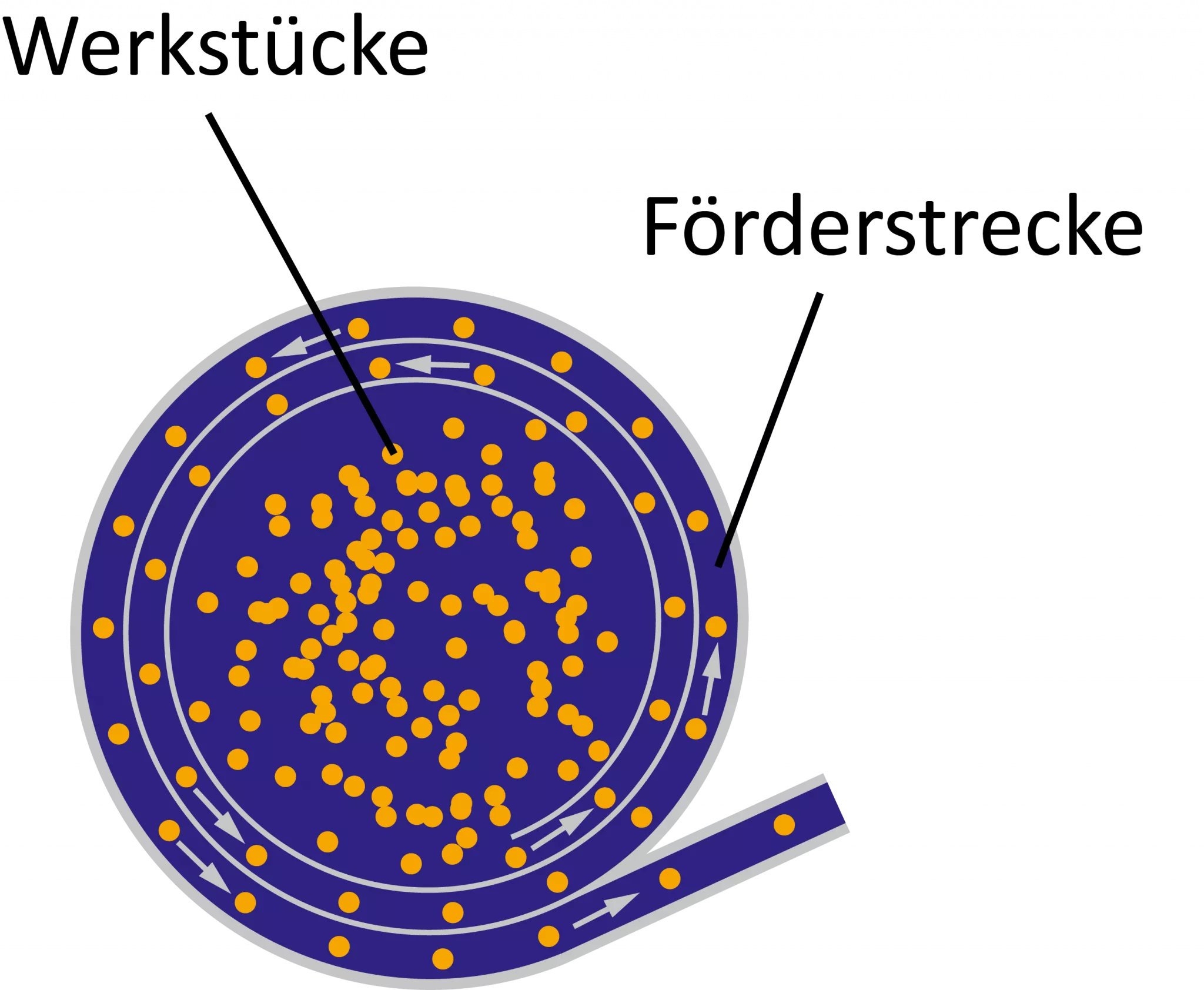

Spiral conveyors are also known as vibratory bowl feeders, parts conveyors, bowl feeders or vibratory bowl feeders. These names can be traced back to the specific design of the bowl feeder and its mode of operation : The upper sorting section of a bowl feeder is shaped like a pot, which consists of a firmly connected cylindrical spiral, the so-called helix. With regard to the helical conveyor track or bowl of the spiral conveyor, a distinction is also made between cylindrical, stepped and conical shapes.

The way it works is relatively simple: an electromagnetic vibratory drive causes the conveyor track of the bowl feeder to vibrate. This vibration initiates a throwing motion in the object lying on the conveyor track, which moves the object in the desired direction. This is also referred to as micro-throwing. Depending on whether specific sorting elements are installed, the objects are also aligned on the conveyor track. This is important if the bowl feeder is used as a sorting conveyor. The sorting elements - also known as baffles - are usually installed by hand. Depending on the design of the bowl feeder, it is possible to make modifications that allow the baffles to be adapted to changing transport objects.

Depending on the production chain in which the bowl feeder is integrated, a number of other parameters can be individually regulated in addition to the baffles. For example, it is possible to change the conveying speed by changing the vibration strength or vibration frequency. Various additional elements can also be connected, for example to regulate the temperature. In addition to spiral coolers, which cool down the goods in the spiral conveyor, there are also heating spiral conveyors, which increase the temperature of the items to be conveyed.

What are the advantages of spiral conveyors and where are they used?

Smaller spiral conveyors in particular are purchased in industrial areas because of their sorting function. This increases the cycle time in downstream work processes, as the small components required are conveyed directly in the correct position. They are used in the automotive industry, medical technology and also in the plastics and electronics industries, among others. However, it is important to prevent signs of wear on the bowl feeder from the outset. This can be achieved, for example, by applying special coatings to the spiral conveyor .