Mechanical Engineering Wiki / Wire EDM

Wire erosion - cutting process with high precision

Like die sinking, wire erosion is one of the ablative manufacturing processes that work according to the principle of spark erosion. In this context, it is often also referred to as wire cutting, wire EDM or wire erosion. The machining process is used in industrial manufacturing processes, for example as an alternative to milling. Wire erosion is characterized by the fact that electrically conductive materials can be machined with the highest precision and considerable cutting speed. The main focus of the range of tasks in wire erosion is the production of prototypes as well as cutting and punching tools.

How does wire erosion work?

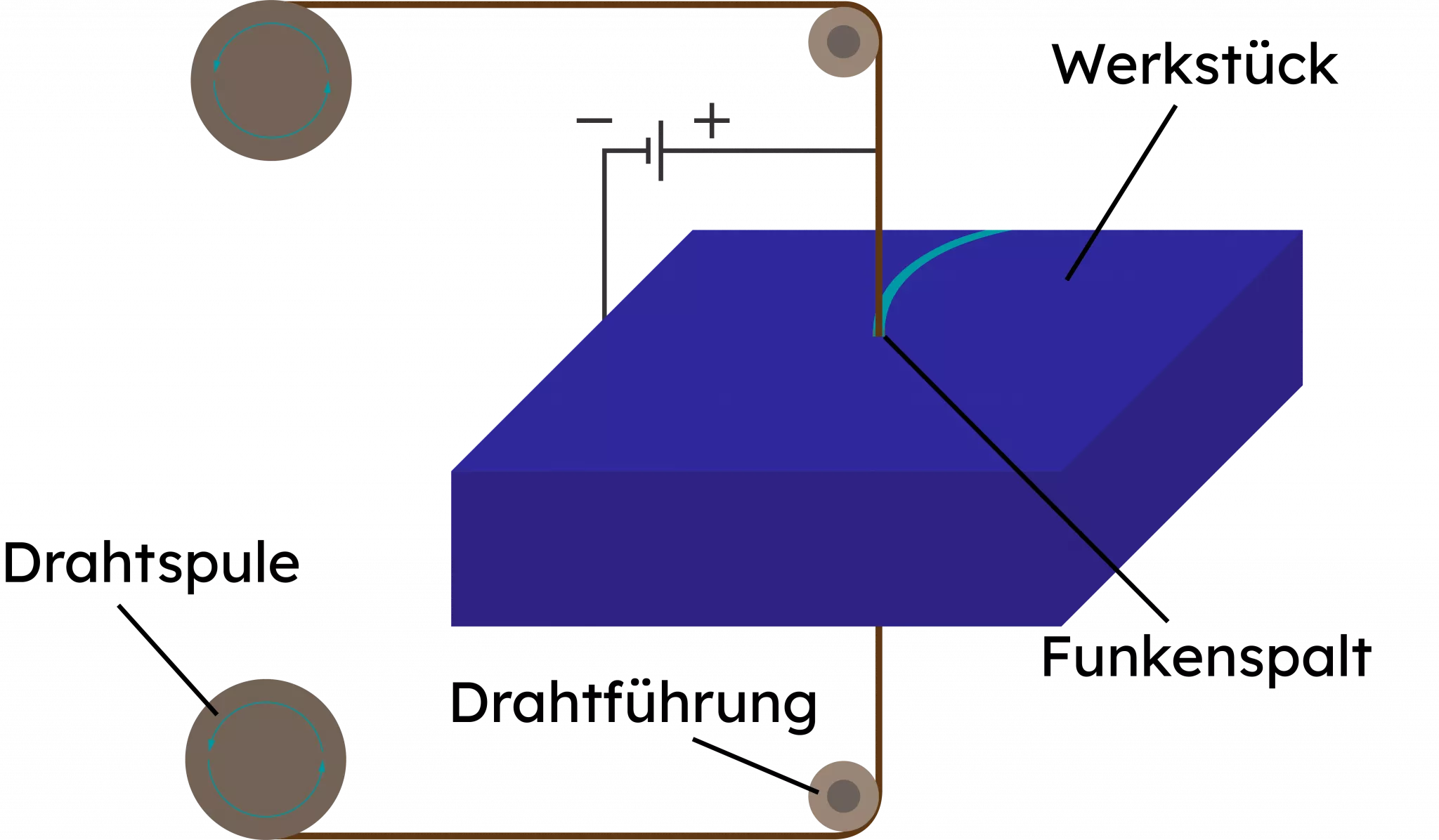

Three elements are of particular importance in wire EDM: wire electrode, dielectric bath and workpiece. Both the workpiece and the wire electrode are in the dielectric bath during the cutting process. This is produced using a non-conductive liquid, for which either deionized water or special erosion oil is used. In some cases, a coaxial jet is used as an alternative to the dielectric bath. The wire is usually made of brass, but can also be made of copper or steel. Wire electrodes with a diameter of between 0.02 mm and 0.33 mm are normally used for wire EDM.

The exact process ultimately takes place in three phases: First, the wire electrode and the material to be machined are placed at a clearly defined distance from each other in advance. It is important that both are charged differently (workpiece = anode and wire = cathode). An electric field is now generated with the aid of electrical voltage pulses (ignition phase) - precisely at the point where the distance between the wire and the workpiece is smallest. The electrically charged particles are accelerated in this field, resulting in a visible spark. This generates a great deal of heat, which causes the dielectric to vaporize and the material of the electrode and workpiece to melt. As a result, a gas bubble forms, which in turn fills with plasma (discharge phase). A pulse pause (pause phase) interrupts the current supply, causing the bubble to implode. The molten material is detached from the workpiece and transported away with the dielectric. Depending on the machine, the processes from ignition phase to pause phase are repeated up to 100,000 times per second. This generates temperatures of up to 40,000°C.

What are the advantages of wire erosion?

Today, wire erosion is a standard process in shaping production. This is due to the various advantages it offers: for example, it is possible to cut extremely complex shapes and very small radii without any problems. Extremely hard materials such as titanium can be processed just as easily as particularly thick workpieces. Even extremely thin parts can be cut with ease, as there is no contact between the workpiece and the tool. Wear is minimal, while at the same time there are practically no reworking costs. After all, wire EDM is known for its perfect cutting edges.

Nevertheless, not all materials are suitable for wire EDM: They must be conductive and of high quality. Otherwise, the cutting results may not be convincing. The materials should also be insensitive to water, as they must remain permanently in the dielectric, especially during longer processing times (risk of rust).

Also important: The three phases of wire EDM must be 100% coordinated with each other or with the material to be processed. Incorrect settings can lead to unclean results or wire breakage.