Contactless chip cards will be increasingly in demand in the coming years. Dual interface cards in particular, which combine contactless with contact-based data transmission, are becoming increasingly popular. Dual interface cards are used as electronic identification cards (eID), electronic driving licenses or health insurance cards. According to market research analyses, demand here will grow by around 22% annually.

The Coil on Module (CoM) technology from Infineon Technologies AG offers many advantages in terms of production costs and the robustness of the cards.

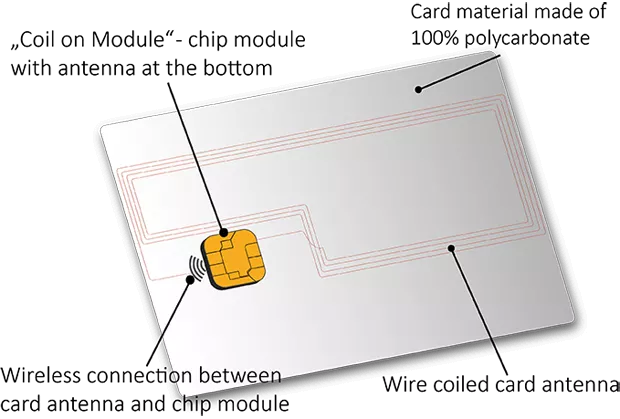

The difference to conventionally manufactured cards is that the contact between the chip module and the antenna is established wirelessly. There is no need for a mechanical-electrical connection.

Technology

CoM chip modules are based on the proven flip-chip technology used in contact-based modules, but communicate with the card antenna via a high-frequency inductive coupling. An additional antenna is attached directly to the chip module for this purpose.

A dual interface CoM card consists of the following main components:

Chip module including microcontroller, antenna and the contact surfaces for contact-based data transmission

Card inlay with antenna, tailored to the CoM requirements

Card body (usually PVC)

Infineon offers a Coil Design Guide, which helps to define the parameters for an optimized layout of the card antenna. The CoM technology supports different antenna technologies (etched, wire-laid,...) so that customers can easily produce dual interface cards compatible with the CoM modules.

Advantages

The electrical contact between the chip module and the antenna on conventional chip cards can be damaged, especially if they are frequently bent. As this is no longer required, cards manufactured with CoM modules are significantly more robust. In addition, the time-consuming process step of contacting the antenna and chip, which is achieved using micro-welding techniques or special soldering processes, is no longer necessary. The chip module can be implanted up to five times faster than with conventional dual-interface manufacturing processes. Existing production lines can be used without further investment. This significantly reduces manufacturing costs and increases throughput figures.

CoM modules are around a fifth thinner than conventional chip modules. This makes it possible to add additional security functions in the form of special security layers.

The design of the card antennas is independent of the chip module used, so that different chip/module combinations can be used with a single antenna layout. This makes the development of a card less complex, fewer different parts need to be kept in stock and development and market launch are faster.

The CoM chip module and the card antenna can be integrated directly into the chip card. If the wire-laying technique is used , whereby the chip module is first implanted on the carrier foil and the antenna is then burned into the carrier material by ultrasound, there is greater freedom in the design of the antenna. The card design becomes simpler and special antenna shapes that guarantee long-term stability are less restricted in their form.

Testing coil on modules - customized solution from MackSmaTec

In order to make use of the many advantages of CoM chip modules, both card manufacturers and module strip manufacturers must be able to rely on a highly professional and specialized test system. Such a system guarantees reliable quality measurements for both outgoing goods inspection (module tape manufacturer) and incoming goods inspection (card manufacturer). This means, for example, that faulty modules can be sorted out directly and removed from circulation.

The PowerTest chip module test system is a test machine for chip modules that performs these tasks for both coil-on modules and dual interface modules as well as contactless and contact chip modules. This has test heads for the simultaneous testing and coding of 32 CoM chip modules in parallel processing. In addition to the basic and parameter tests, existing software solutions also enable the initialization and personalization of the modules. In addition, an automatic separation station can be integrated as an option. In total, the PowerTest enables a throughput of up to 77,000 chip modules per hour, but still impresses as a high-performance system with simple operation.