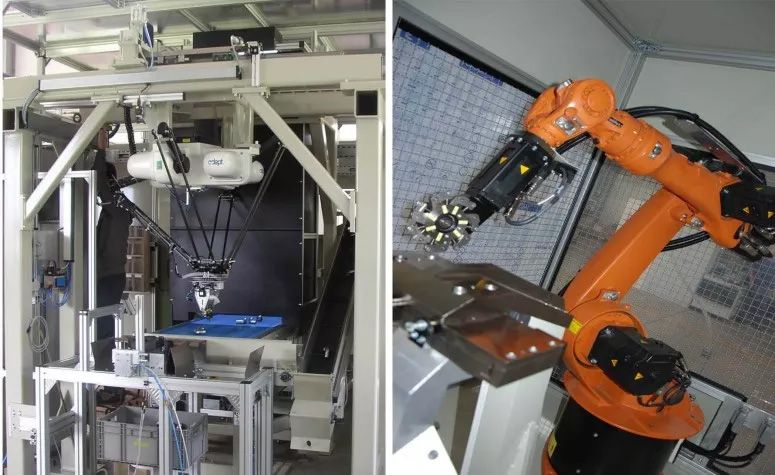

An industrial robot is a programmable machine for assembling, processing or handling workpieces. Industrial robots - also known as industrial manipulators - are specially designed for use in an industrial environment and are used in automotive manufacturing, for example. They usually consist of a robot arm, the controller and the gripper or tool. Such robots are often also equipped with sensors - once programmed, the work process is carried out autonomously or can be varied depending on the information from the sensors.

What industrial robots are there?

Industrial robots are available in a wide variety of designs and from a wide variety of manufacturers. They are usually purchased as a basic device and then adapted to their task with tools that correspond to the desired application.

Industrial robots are categorized according to the kinematics used:

- Parallel kinematics

- Serial kinematics

Serial kinematics consists of a series of arm parts, whereas in a parallel robot, several joints act directly on the moving tool carrier. In a parallel robot, the drive is not loaded with the mass of the following drives and links - this results in only a small moving dead weight and the mechanics are therefore more precise. A hybrid robot is a middle ground between a serial robot and parallel kinematics; its drives are not completely fixed.

The load capacity is a decisive criterion for industrial robots. It specifies the maximum mass that can be attached to the end of the gripper arm. The range for articulated arm robots is from 2.5 kg to approx. 1,700 kg. However, accuracy and dynamics are also important parameters. Today's industrial robots usually have six axes - the term industrial robot can only be used for three axes or more.

The automotive industry uses industrial robots in large numbers for painting and assembly work. The great advantage of robots is that the motion sequences are freely programmable and can therefore cover different handling sequences for different vehicle models. Due to the large number of robots used, they are now manufactured in large quantities and prices have fallen sharply in recent years. As a result, the typical articulated arm robot is now also used in many other industries.

Gripping technology - the heart of the system

Gripping technology is the heart of every industrial robot - it is responsible for its optimal use. The articulated arm robot is modeled on the human arm. Accordingly, it is also an articulated arm robot that sticks in the minds of people outside the industry as an industrial robot and is what they think of when they hear the term. However, this is only one of several design variants, as there are the following gripping systems:

- Vacuum grippers

- Mechanical grippers

- Magnetic grippers

The gripping system is the connection between the robot and the workpiece. Gripping takes place via shape pairing, force pairing or material pairing. The robot arm consists of a series of rigid links that are connected to each other by means of thrust and rotary joints and can therefore be used multifunctionally. The joints are adjusted by controlled drives. At the very end of the arm is the base and at the other end is the freely movable section, which is fitted with a gripper or tool.

Drive systems - Three-phase servomotors with resolver

Today, three-phase servo motors are used to drive modern industrial robots. These are equipped with a resolver that supplies two signals when the axis is rotating. It is permanently connected to the motor axis and allows a counting pulse to be generated and the rotor position to be detected. This makes it possible to record the position of the axis and the robot.

In the past, the motors were equipped with two different systems to detect the position on the one hand and the rotor position on the other. They were connected with separate cables and were mounted on the drives. This meant that in addition to the classic power cable, two cables had to be laid to the control system for robots of this generation.

Robot control - coordination of the axes and the gripper

The actual robot controller is responsible for coordinating the axes and ensuring that the gripper moves along the programmed path at the desired speed and accuracy. It also processes the sensor signals from the gripper and for the gripper actuators. In some task areas, different tasks result in complex handling sequences, meaning that different movements have to be carried out.

A great deal has happened in the field of control systems in recent years and robots are controlled by PC. In 1999, the company Dortmunder Roboterbau designed the first robot with PC control and a touch-screen user interface. The PC systems are now highly sophisticated and offer a number of advantages. These include BUS technology, which allows a simple interface to the robot axes and other peripherals. Various programming languages, such as NQC, VAL/VAL2/VAL3, KRL and RCCL , mostly developed by the manufacturer, are used as programming languages. In the future, the approach will be to make robot programming as simple and user-friendly as possible.

Another control option is the use of a programmable logic controller (PLC). This makes it possible to control the robot. The PLC is connected to the robot together with sensors and the so-called actuators via an interface. Sensors are all inputs that communicate what is happening to the robot, such as light barriers. Actuators, on the other hand, are connected to the robot's outputs, such as the gripper arm.

The robot applications and the PLC are usually connected via a fieldbus. This reduces the amount of wiring required.

Ethernet-based fieldbuses, e.g. Profi-Net , are now used in modern systems. These fieldbuses are flexible and fast.

Protective devices - protecting people from potential hazards

Industrial robots increase efficiency and make physical work easier for people - but they also entail risks and dangers. Appropriate protective equipment is available to protect people from these hazards. For example, the workspaces of people and machines must be separated from each other, as it is not possible for a robot to perceive its environment itself. To ensure that operator protection is selected correctly, a risk analysis is first required.

Only when all the potential hazards of a machine have been identified, the risks determined and the necessary protective equipment defined, can the appropriate protective measures be selected. These must protect people, but must not restrict the operability and functionality of the robot.

A distinction is made here between

- Isolating protective devices

- Electro-sensitive protective equipment

Guards, fences and enclosures are used as guards. These are permanently installed between the user and the danger zone. Movable guards are hinged doors or sliding doors, which have the same features as fixed guards, but the opening process is monitored. For example, the machine stops moving automatically when the user enters the area.

Light grids and light barriers are widely used as electro-sensitive protective equipment. If the light beam is interrupted, the machine is switched off. Special light grids detect fingers or other body parts and are also used as protective devices. They have the advantage of being much more flexible. In addition, they can be interlinked and automated with systems and are able to differentiate between materials and people.

Light curtains allow a relatively flexible installation, but the distance of the light curtains to the hazardous movement depends on their switch-off time.

If you have any questions or require further information on robot applications, please contact us!