Identification options are required to manage access authorizations or provide individual configurations for specific people. These tasks are often performed by ID or smart cards consisting of several layers using various unique and security features. Depending on the configuration, they work with direct contact or contactless. Security features on smart cards are generally divided into physical or digital as well as visible and invisible.

Security features on chip cards prevent the following risks:

Unauthorized reading of information (confidentiality)

Unauthorized modification of information (integrity)

Unauthorized withholding (availability)

Unauthorized modification of identifying information (authenticity)

This blog entry will present some important applied security features.

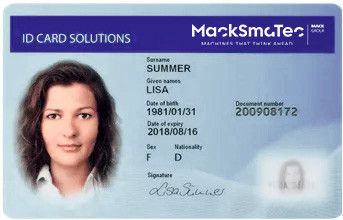

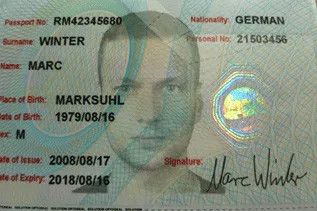

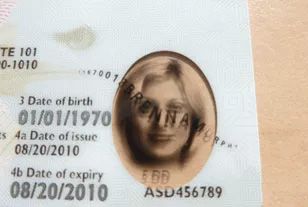

Photo:

The most obvious and most commonly used security feature for personal identification is a passport photo. These are applied to a card in high quality by color printing, usually using the "ink-jet drop-on-demand process" or, more rarely, laser engraving and other techniques. Passport photos offer the great advantage of functioning without a reader. Furthermore, additional biometric data makes photos on driving licenses or ID cards machine-readable.

Ghost photo:

A ghost photo is a semi-transparent graphic, usually another photo of the cardholder, which is applied to the card. However, ID numbers or logos with reduced transparency are also printed on the card background. The process is inexpensive and can only be copied with great effort.

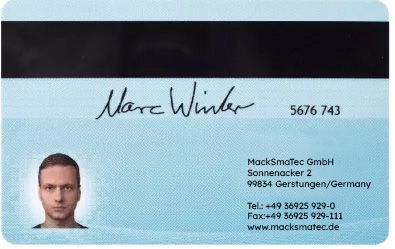

Signature:

In addition to photos, reference signatures on ID cards are a widespread security feature, for example when paying with a debit or credit card. Security writing fields increase copy protection by ensuring that the writing surface is obviously damaged by friction or contact with chemicals.

Laser engraving:

Names, card numbers or other inscriptions are engraved into the card using various lasers with different wavelengths to protect the material. The "insertion" process means that the imagery cannot be removed. The markings to be applied can be programmed easily and variably.

Barcode:

Barcodes allow computer-aided unique identification. They can be applied to any card in one or two dimensions and are particularly cost-effective. QR codes can also be printed.

Embossing (embossing):

Embossing the back of a card creates raised areas on the front. This allows numbers, names or logos to be displayed 3-dimensionally . In addition to its aesthetic appearance and practical use, for example for the analog "swiping" of credit cards when issuing receipts, the process makes it more difficult to copy cards. Furthermore, haptic features make it easier or possible for visually impaired or blind people to "read" the cards.

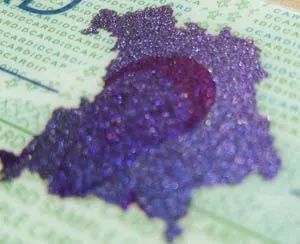

Hologram:

A hologram is a 3-dimensional graphic that can be placed freely on the card surface using complex processes involving multi-layer films and laser technology before lamination. Depending on the viewing angle, the image has a different three-dimensionality. An additional matt film makes it more difficult to read the graphic. The 3D effect is inexpensive, durable and is considered to be largely forgery-proof.

Holographic laminate (overlay):

The surfaces of personalized cards are protected against scratching, colour loss and destruction of electronic components with laminate layers. Overlays are laminating films with an applied holographic image structure. This method can be used to create two- or three-dimensional images.

Effect inks:

UV or IR active inks can be used to create simple lettering, patterns and logos as well as images, which can be invisible under normal light. Cards labeled with UV or IR inks glow under ultraviolet or infrared light. Furthermore, so-called OVIs (optically variable inks) are used, which change color when the incidence of light changes. Another application of effect inks are so-called thermochromatic inks. These change color or become transparent when heat is applied, e.g. in the form of friction. Such imaging can only be produced using complex printing processes or the blank is supplied with a special coating and further individualized using lasers. In addition, these graphics can be realized depending on the viewing angle. The processes mentioned protect against simple color copying or scanning.

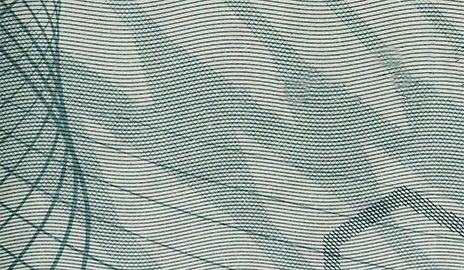

Guilloché:

Closed, interwoven lines are applied to the top film on the front and back. The fine lines often form asymmetrical patterns such as ellipses or circular paths. Manipulated cards can be recognized by interrupted guilloches. They can only be realized by printing and cannot be copied.

Micro lettering:

Micro lettering looks like simple lines to the naked eye. With a font height of less than 0.3 mm, they can usually only be read with a magnifying glass or microscope. Color and font are freely selectable. Due to its fine structure, it cannot be copied, only printed.

Magnetic stripe:

Many cards have an inexpensive magnetic stripe coated with a metal oxide layer. The data on it is read electronically using a swipe or insertion reader. There are two main types of magnetic stripe in use, HiCo (High Coercivity) and LoCo (Low Coercivity). They differ in the magnetic flux density required for reading and writing. LoCo magnetic strips work at around 30 mT, for example on debit and credit cards. External weak magnetic fields, such as that of an unshielded loudspeaker, can erase the data on them. HiCo magnetic strips , on the other hand, work at around 300 - 400 mT and are very robust against external influences.

Microchips:

Compared to magnetic strips, microchips offer the advantage of not only being passively readable, but also actively working with low computing power, their own operating system and read and write-protected memory. These small microprocessors therefore enable the use of complex encryption techniques. With highly developed technology, microchips are now secure against metrological reading of the applied encryption algorithm.

RFID:

While conventional microchips transmit data via contact, chip cards with RFID inlays do so contactlessly. The antenna in the card is supplied with energy via an electrical field emitted by the reader. The contactless nature of the technology makes it easy to handle and reduces soiling and wear.

CLI / MLI:

CLI (changeable laser image)/ MLI (multiple laser image) are tilted images that show different graphics depending on the viewing angle. Transparencies are stacked individually or one on top of the other and irradiated with lasers from different angles. The use of CLI/MLI technology makes simple copying more difficult while remaining visually verifiable. The technology is used on the German driver's license, among other things.

Invisible Personal Information:

Personal information is stored hidden on the data carrier, for example a date of birth in the background of a passport photo or similar. With the help of software-based encryption processes, unique features are encoded and applied to a card so that they are invisible to the human eye. Only with special lenses and the appropriate software are the cards then machine-readable.

Conclusion

Today, ID and smart cards enable practical and secure personalization in many areas. The spread of these chip cards will continue to increase significantly in the coming years, which will also increase the demands on the security features of the cards. Although protection against copying and misuse can be achieved in a variety of ways, it is only the totality of the features used that creates the necessary security of a card. In addition to optical features, cryptology and software are playing an increasingly important role. Finer chips, new materials and highly developed software solutions increase the user-friendliness and security of personalized plastic cards.