Mankind began to automate simple processes back in ancient times. The philosophers of ancient Greece founded technical mechanics and developed small machines that were powered by water, air pressure or, in the case of the heron ball, steam. However, most of these machines were not used to perform work; they were mostly just small models that were regarded more as toys. During the Renaissance, scientists began to build life-size automata. Leonardo da Vinci had already drawn a robot that could move its arms and turn its head. This development reached a new dimension with the beginning of industrialization. Today, automated, electronically controlled processes are commonplace and systems have been created that humans would never be able to master without automation.

Basic principle of automation

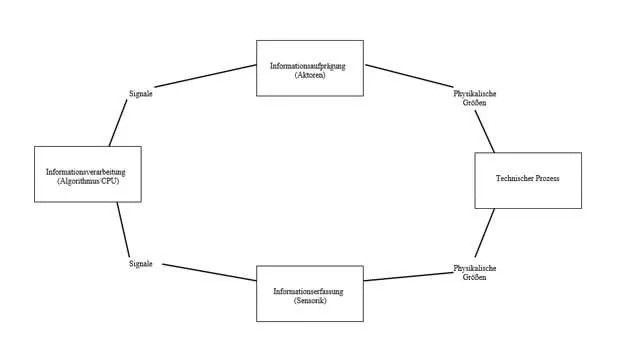

The aim of automation is the targeted influencing of dynamic processes, for example the control of a production plant. The basic structure of an automated system can be divided into 4 areas that form a closed loop.

Sensors record process-influencing physical variables such as pressure or temperature and convert them into signals that we can process further. In most cases, electrical signals are used. With the help of a mathematical algorithm, the recorded information is converted into suitable signals to control the actuators, which then generate physical variables that influence the technical process.

Programmable logic controllers

Programmable logic controllers (PLCs) are the most widely used automation devices today. They can be found in almost all areas of industry, in transportation and storage systems or in home automation.

Programmable logic controllers appeared on the market in the early 1970s. They were developed to replace the relay and contactor controls that had been used up until then. These were very inflexible and limited in their scope of performance due to the large amount of space they took up and the complicated programming involved in establishing connections.

With the rapid development of microelectronics, the performance range of PLCs has steadily increased. Modern programmable logic controllers have complex calculation and control functions, operating and monitoring functions, as well as communication capabilities.

Structure and function

Programmable logic controllers contain all the necessary modules to implement a closed automation circuit. The automation device has input and output modules which can be fitted with sensors or actuators. A central unit processes the input signals according to the control algorithm and transmits the corresponding control signals to the actuators via the output modules.

[Insert image: diagram-structure-memory-programmable-control.jpg]

The input modules contain overvoltage protection, interference pulse filtering and galvanic isolation, which is usually implemented using optocouplers. This prevents interference pulses from reaching the central unit. The output modules also contain galvanic isolation, short-circuit protection and an amplifier. LEDs are often fitted to the inputs and outputs to indicate the current status.

The central processing units of modern programmable logic controllers consist of powerful microprocessors that enable fast processing of counting functions, arithmetic operations, time functions and logical comparison operations. The control instructions are processed by the control unit one after the other and repeated cyclically. As soon as the last instruction has been processed, the control unit starts again with the first instruction. The time required for a complete program cycle is called the cycle time and is usually in the range of milliseconds.

Programming

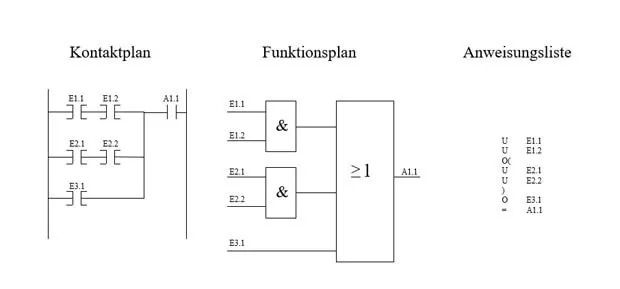

Programmable logic controllers are programmed using standardized function block and instruction libraries in different types of representation.

The ladder diagram representation (LD) is similar to a circuit diagram, with the individual current paths arranged horizontally below each other instead of vertically next to each other. In the function block diagram (FBD), the individual operations are represented by square symbols. The individual functions can be easily distinguished within the square using function identifiers. The inputs are arranged on the left, the outputs on the right, and are connected according to the task. The instruction list (IL) places the least demands on the programming device, but is relatively confusing.

The program of a PLC is a sequence of control instructions consisting of the operation part and the operand part. The operation part describes the function and the operand part describes with whom it is to be carried out. Linear programming is possible for simple tasks. The instructions are written step by step. For larger projects, a structured subdivision of the process steps is necessary. In this way, individual modules can be created, which together process the desired task. This allows the task to be distributed among several programmers. The blocks created can be stored in a library and reused. Generally valid blocks can be purchased from PLC manufacturers.

Modularity principle

Programmable logic controllers have a modular structure, which enables application-oriented configuration. Depending on the task, only certain components are required. The minimum equipment consists of the frame, which serves as a carrier for the individual modules, the power supply, the central module and an input and output module.

Depending on requirements, a selection of input and output modules must be made; this relates to both the number and the properties with regard to signal level, source resistors or other special requirements.

Special communication modules can be integrated for the connection of special peripheral devices, whereby, for example, a PC can be used for process visualization.

The central module can be dimensioned for the specific application in terms of computing speed and available memory.