OEM is the abbreviation for Original Equipment Manufacturer, which in German roughly means original equipment manufacturer or original equipment manufacturer (OEM manufacturer). The term has different meanings in different industries.

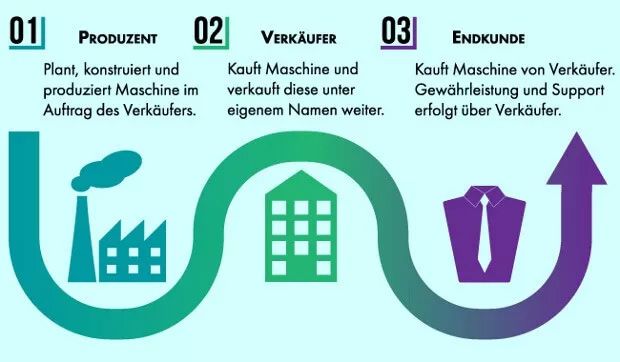

On the one hand, a manufacturer of products that are produced in its own factories but not marketed itself is referred to as an original equipment manufacturer or OEM manufacturer. In addition to their own sales, many manufacturers supply their products to other companies that sell these products under their own name. These products can be slightly modified as OEM versions and adapted to the wishes of the seller.

In the automotive and mechanical engineering industries, however, the term is used in the opposite sense. Here, companies are referred to as OEMs if they combine self-manufactured or third-party components into complete vehicles or machines and offer these independently on the market.

A third meaning arises in the IT sector. Here there is OEM software and OEM hardware. OEM software is sold together with the hardware and is only functional with this specific hardware. As a rule, OEM software is a main version with limited functionality.

Sale of OEM products

OEM production has many advantages for both the seller of the goods and the manufacturer. Above all, there are cost advantages on both sides.

For the manufacturer, the costs for marketing and sales are reduced or even completely eliminated if only OEM products are sold. This is very important due to constantly growing competitive pressure, as it means that more resources are available for research and development, as well as high-quality production.

The seller of the products is spared the costs of independent product development and setting up a production line. This leaves more resources for marketing and building a well-known name. In addition, the time to market is shortened enormously, as there is no need for costly in-house development and the know-how of established manufacturers is used instead. If demand increases, certain production volumes can be achieved much more quickly, as the OEM manufacturer usually already has the capacity and does not need to build it up itself.

Another advantage for the OEM manufacturer is that it can increase the sales of a product without having to make major investments of its own. For example, a product can be sold in Germany by the company based and producing here itself, while additional identical products are sold as OEM products via external sales companies abroad. This also eliminates export costs for customs duties and transportation for the manufacturer.

In the case of independent sales by the manufacturing company, this company is legally responsible for warranty and product liability. A stock of spare parts is necessary. In the case of OEM products, this obligation is transferred to the dealer, which reduces the manufacturer's warehousing costs.

OEM in automotive and mechanical engineering

In the automotive sector in particular, the final manufacturer generally handles sales itself. As already mentioned, a different definition of the OEM applies here. As automobiles and large machines consist of many individual parts, the number of suppliers of individual components is very large. This results in large value chains, with suppliers being subdivided into tiers. Tier 1 suppliers are manufacturers of systems that are supplied directly to the OEM. This is followed by Tier 2 suppliers, manufacturers of modules and components that are generally supplied indirectly to the OEM, as well as raw material and parts suppliers (Tier 3).

The main reason for the external production of individual components is the ever-increasing complexity of automobiles or large machines. While Henry Ford was still able to develop and produce all individual parts in one factory in 1904, this seems almost impossible with today's automobiles.

There are also cost savings for the OEM, for example the production of individual components can be relocated to low-wage countries. The cost-intensive development of systems is transferred to companies that have already acquired know-how in these areas, which saves further costs. As a rule, this also increases the quality of the end products, as the system suppliers can usually draw on years of experience in their respective fields.

The disadvantage is dependence on suppliers, as a chain is only as strong as its weakest link . Unnoticed errors in parts production, such as the lack of bending strength of a metal component, can lead to major defects in the end product. Bottlenecks at suppliers can also lead to difficulties for the OEM. This also applies to weak sales by the OEM, which can lead to drastic losses for suppliers who only deliver to OEMs and are dependent on their demand.