Mechanical Engineering Wiki / Die sinking

Contactless machining of the hardest materials

Die sinking is a process that can be classified as spark erosion . This process is based on scientific theories about the eroding force of electrical charges that were established as early as the 17th century. Today, spark erosion in general and die-sinking in particular make it possible to process electrically conductive materials with pinpoint accuracy. If these cannot be processed (precisely) with other techniques, or only insufficiently so, die-sinking EDM can provide a remedy. The main focus of die-sinking EDM is the production of injection molds and die-casting molds.

Die-sinking EDM - metal processing with an electrical charge

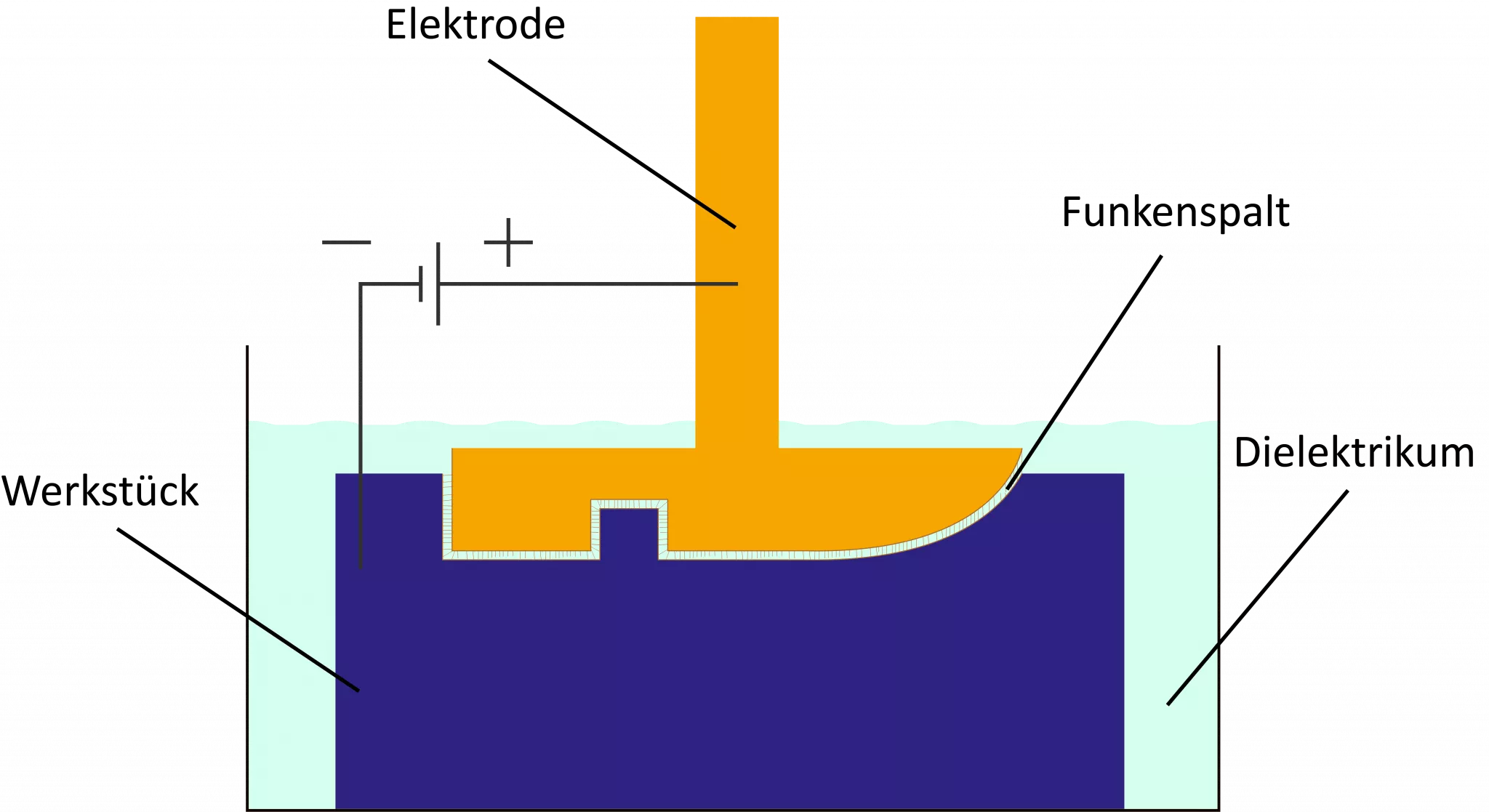

Spark erosion is primarily used to process metals that are electrically conductive. Sparks are generated using an electrode tool, which in turn strike the workpiece and cause controlled removal of the material . The entire process takes place in a non-conductive medium, also known as a dielectric. Water or oil is normally used for this. Spark erosion processes are made up of four different variants: drill erosion, wire erosion, disk erosion and die-sinking erosion.

In die-sinking EDM, a specially designed electrode must first be produced. This has the negative shape of the surface that is later to be produced on the workpiece. In the bath filled with the dielectric, the electrode is brought up to a tiny gap of less than one millimeter to the workpiece. Only then does the spark generation begin, which ensures that the material is removed from the surface of the workpiece according to the specified shape. The size of the spark gap, as well as other parameters such as the intensity, frequency or duration of the discharges, have an effect on the removal rate on the workpiece and must be set precisely accordingly.

Advantages and disadvantages of die-sinking EDM

Spark erosion can be used to precisely machine very hard materials. Even complex and very fine surfaces can be realized on the workpiece. The realization of injection moulds and prototypes is therefore one of the most widespread areas of application for die-sinking EDM. Die-sinking EDM also has the advantage that it softens the boundaries of the other variants of spark erosion: if wire erosion, for example, can primarily cut, die-sinking EDM is in some ways more like pressing, in which only the pre-set surface part of the workpiece specified by the electrode is actually machined.

The disadvantages of die-sinking EDM include the costly and time-consuming production of the electrodes and their wear during use. It is often necessary to machine or rework the workpiece in several steps due to so-called burn-off (erosion on the electrode). In addition, the entire process is limited to workpieces that have electrical conductivity.