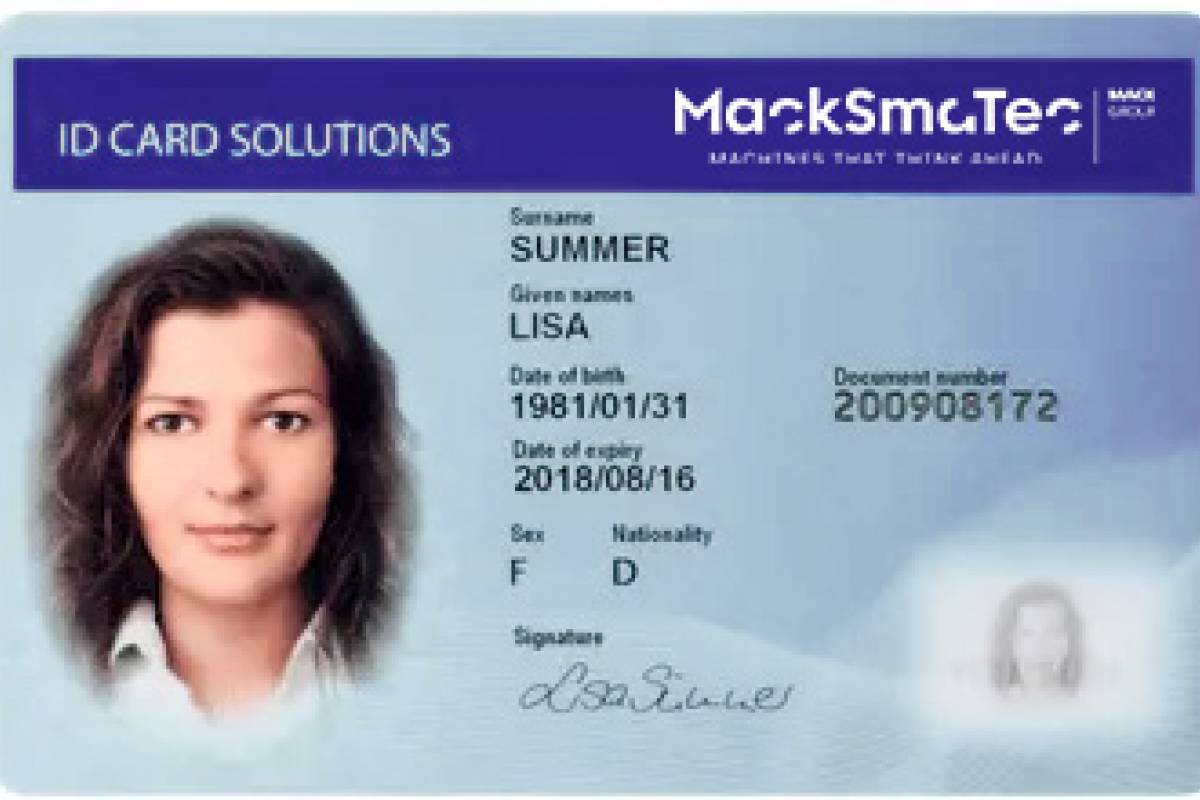

It's hard to imagine our daily lives without them. They are used everywhere in the form of EC cards, season tickets for swimming pools or student ID cards: plastic cards with an integrated microchip. They store our most important personal details and make them available when needed.

But how does this technology work and how can such cards be produced?

In an earlier blog post , we looked at the exterior and various printing processes. Now we want to take a look inside smart cards and give you a little insight into how they are produced on an industrial scale . For the sake of simplicity, we will first look at the older and less complicated form of contact smart cards.

Structure of a contact smart card

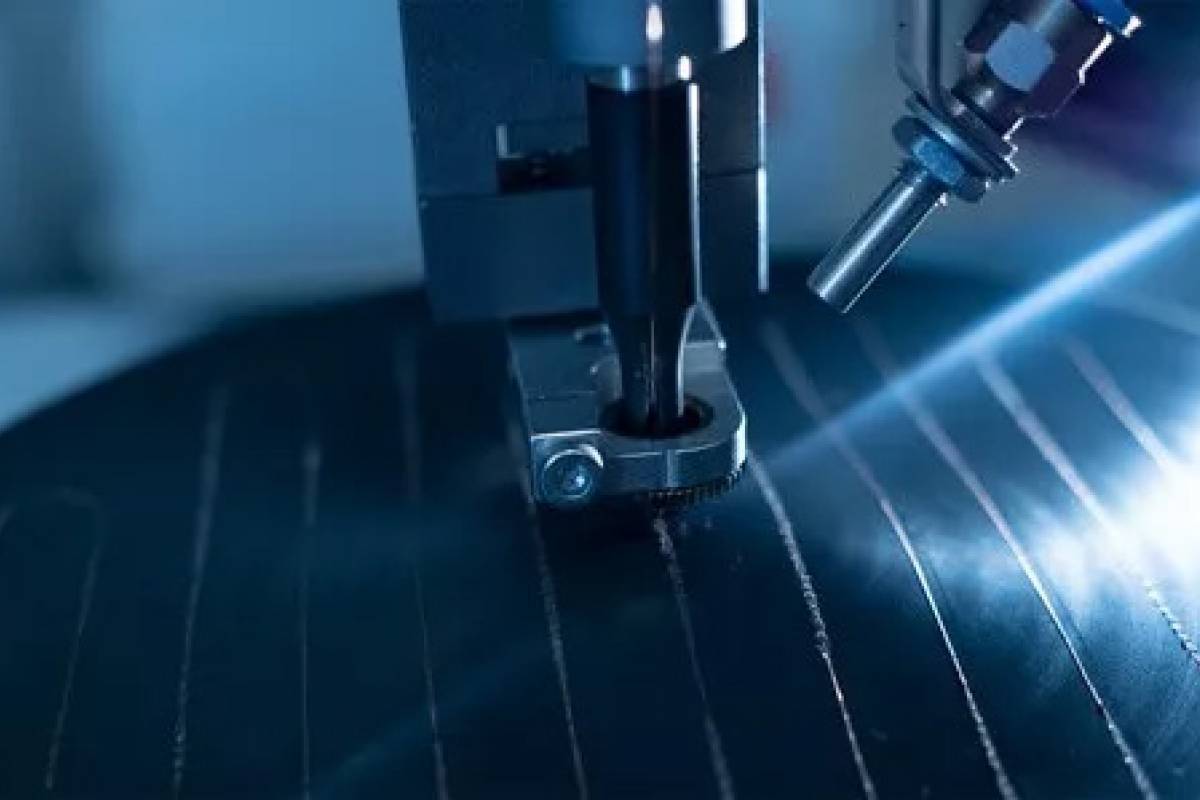

Basically, a chip card (integrated circuit card [ICC]) consists of a carrier material (in the form of a plastic card) into which a cavity is inserted. An integrated circuit (e.g. in the form of a µController) is glued into this cavity. This in turn is connected to a contact surface via bonding wires and finally surrounded by a potting compound (special epoxy resin). The potting compound, also known as the "glop top", protects the sensitive bonding wires and the chip body from environmental influences such as moisture and mechanical stress.

As a fast curing time is required in industrial mass production, UV-curing potting compounds are mainly used today (for approx. 90% of all cards). In order for curing to take place , the potting compounds must be translucent. Alternatively, thermally curing potting compounds are used. These do not have to be translucent, but with a curing time of up to 3 minutes they are clearly too slow for mass production and form a relatively brittle mass when cured. Modern UV-curing potting compounds, on the other hand, only require around 30 to 40 seconds to cure, which is more in line with the requirements of chip module manufacturers. With modern potting machines that use LED technology instead of UV discharge lamps, which leads to an even faster curing time and very short start-up time, throughputs of up to 40,000 modules/hour can be achieved.

Types of chip cards

Different chips are used depending on the application. They are differentiated according to the type of data storage, the computer and the interface to the readers.

Memory chip cards

Memory chip cards are the simplest form of chip card. As a rule, they consist of nothing more than a non-volatile memory, special logic and an interface for inputting and outputting data.

The memory used is usually an EEPROM (Electrically Erasable Programmable Read Only Memory), which are memory cells that can be programmed and erased electrically and retain their memory contents even after the power is switched off. In the past, EPROM (Electrically Programmable Read Only Memory) was also used, which works in a similar way, but can only be erased with the help of UV radiation, which makes it very difficult to change the programming (e.g. when changing residence).

Microcontroller cards

Microcontroller chip cards contain a microcontroller, which is structured like a complete computer and has various types of memory and a central processor (CPU).

CPU = Central Processing Unit

As the name suggests, the CPU is the central processing unit of a microcontroller. It can calculate, organize and control the data to be stored or output according to predefined rules. Microcontroller cards therefore offer significantly greater functionality and increased security against tampering than simple memory cards.

In addition to those mentioned above, microcontrollers also contain other types of memory:

ROM = Read Only Memory

ROMs have a fixed content that cannot be changed; their content is predefined in the chip's manufacturing process and cannot be changed (e.g. the BIOS on PCs was originally on a ROM, but EEPROMs are often used today).

RAM = Random Access Memory

RAMs are volatile memories that can be reprogrammed electrically and serve as working memory during operation.

In modern chip cards, RFID technology (radio frequency identification) also enables contactless reading. With current credit cards, a combination of both technologies (dual-interface card) enables both contactless and contact-based payment. Modern production mechanisms make it possible to place the entire electronics (in the case of contactless chip cards, including the interface, in the form of an antenna) on thin foils, so-called RFID inlays (also known as smart labels). Integrated microcontroller chips can be replaced by circuits with a central microprocessor chip (similar to the internal structure of a PC) in order to achieve higher computing speeds for demanding applications. Coprocessors are also used specifically to encrypt sent and received data in order to reduce the load on the CPU.

Application examples

Telephone prepaid cards

Telephone prepaid cards are usually memory chip cards with a security logic. The first telephone cards used in France had EPROM memories that were gradually invalidated when used.

Bank cards (electronic cash)

EC cards are equipped with a magnetic strip as standard. However, this only stores static information and therefore offers no secure identification options and can also be copied very easily. Since the year 2000, newly issued cards have therefore been equipped with an additional chip. In contrast to a magnetic strip, this chip can respond to requests from the reader and thus protect the payment with a PIN, for example. The data stored on the chip cannot be read out completely, so the chip is also much more secure against possible copying. Since 2011, it has been mandatory in Germany to use the chip for electronic cash.

Health insurance card

The German health insurance cards used until 2014 only contained the patient data relevant for medical billing, thus entitling the holder to visit a doctor, and contained a simple memory chip. The electronic health cards, which were finally introduced on January 1, 2015, contain a microcontroller and enable additional functions beyond medical billing. They contain additional information such as medical history, blood group, allergies and other emergency information.

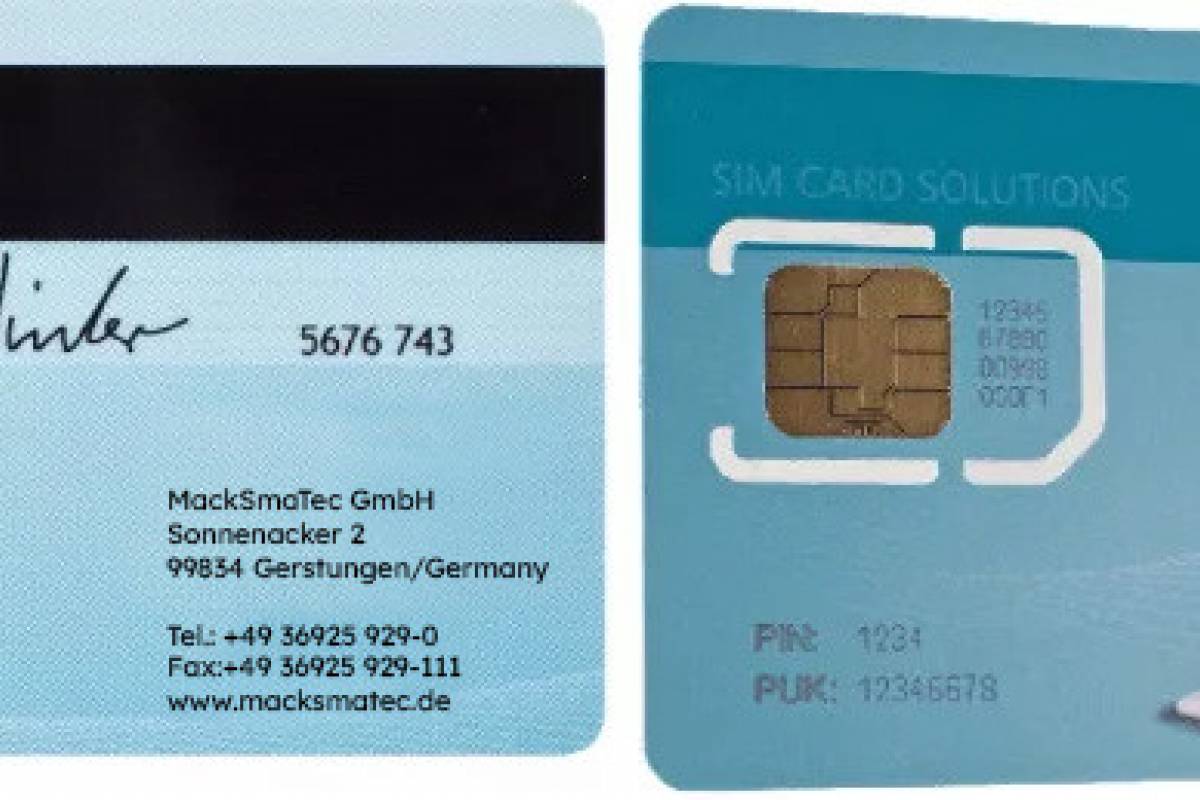

GSM card

GSM (Global System for Mobile Communication) is the name for the standardized mobile phone network used in Europe and some Asian and African countries. GSM standards specify a "Suscriber Identify Chipmodule" (SIM) in the form of a microcontroller card to identify the subscriber to the network. The SIM contains the necessary intelligence for identifying the subscriber and, depending on the type, various additional auxiliary functions.

If you are interested in other technologies in the field of card systems and chip modules, please feel free to contact us at any time!