Due to changing market conditions and the resulting adaptation of industrial production to these, hybrid assembly systems are becoming increasingly important. They represent a combination of manual workstations and fully automated production. The main task of automated systems is to support people in the assembly process during monotonous or labor-intensive work steps.

Basic forms

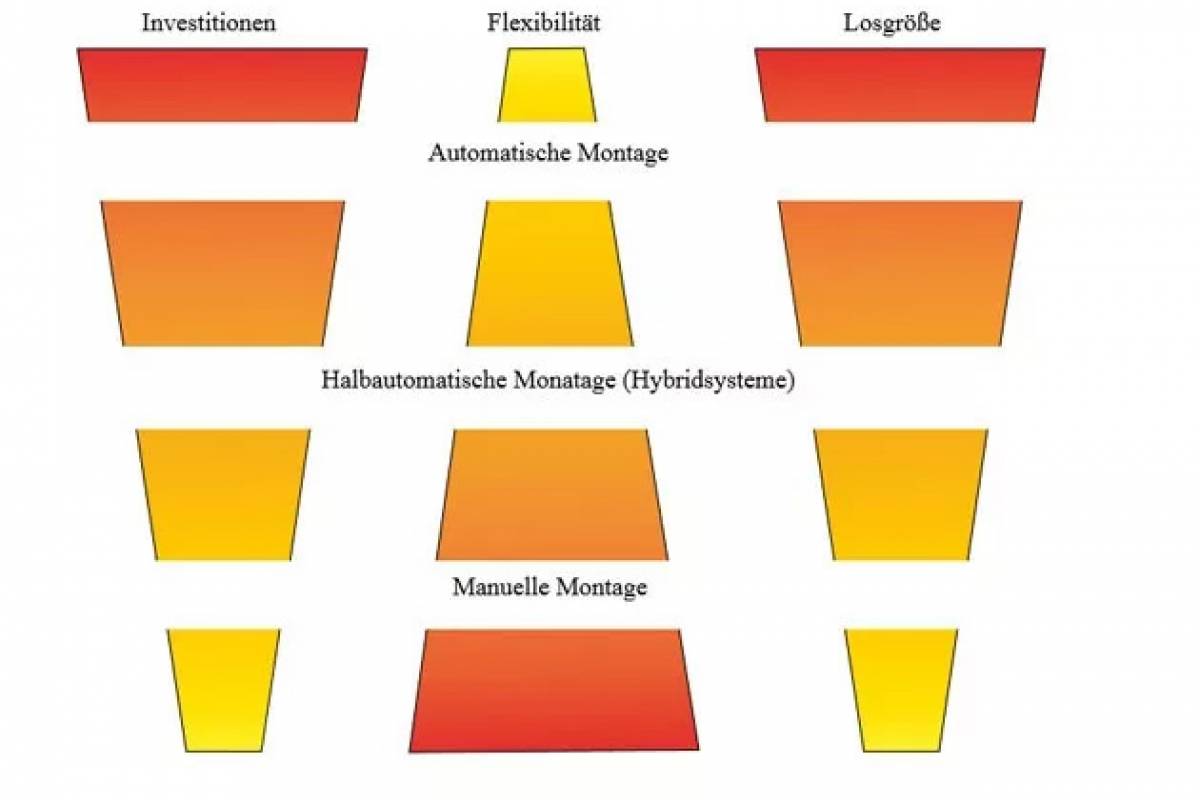

Similar to manual and automated systems, hybrid assembly systems can be categorized according to certain factors (see illustration).

The biggest challenge with hybrid assembly systems is the temporal coupling between man and machine. One way to overcome this is to use buffer zones in which the automatically produced parts are first stored temporarily. The assembled objects are then not passed on in line with the machine cycle, but are passed on by the human operator without any timing.

The type of assembly process also has a major influence on the productivity and efficiency of hybrid assembly systems. The automatic systems can be used to produce individual pieces or sets of a certain number, with set-by-set production being preferred. An example of this is the assembly of printed circuit boards in electronics assembly, which are usually produced in batches of, for example, nine pieces per automatic cycle. In order to minimize the changeover times and thus the secondary costs, in most cases several batches of the same product are produced one after the other.

Advantages of hybrid assembly systems

If correctly dimensioned, hybrid assembly systems offer a high degree of flexibility. By adapting the allocation of manual workstations to the respective order situation, it is possible to react quickly and easily change the quantities produced. In times when orders are low, the production volume can easily be reduced by, for example, only filling 50% of an assembly line containing several manual workstations .

Hybrid systems entail a lower risk of bad investments than fully automated lines, as the degree of automation can be adapted to the given quantities over the course of use. The assembly system can initially be used purely manually in the start-up phase and then progressively automated over time as production volumes increase.

With good planning, a hybrid system consists largely of product-neutral components that can be reused at the end of a product life cycle.

Hybrid assembly systems are therefore particularly suitable for the production of small appliances with many variants and small batches and represent a good alternative to relocating assembly to a low-wage country.

Hybrid assembly systems in rotary indexing design

Hybrid assembly workstations in rotary indexing design are suitable for smaller assemblies in the medium quantity range. They consist of a rotary table on which a set of products to be manufactured is placed. A worker sits in the front area and performs the manual work steps, while automated processes run in parallel in the background. The biggest advantages are the low purchase price and space requirement, as well as the assembly in sets, which significantly increases cost-effectiveness.

It is possible to automate work steps that can, in principle, be easily carried out by hand, but are better carried out automatically for quality reasons. For example, the application of adhesives or greases can be dosed very precisely.

Such systems offer major advantages over manual assembly, especially for work steps that cannot be carried out manually, such as pressing rivets. In classic workbench assembly, the worker inserts the assembly into a device and operates it, while the device remains inactive. This results in a secondary effort, which is not necessary with a hybrid assembly system in rotary indexing design.

Hybrid rotary indexing assembly systems are available in various sizes between 300 and approx. 2000 mm turntable diameter. The selection depends on the complexity of the product, the number of individual parts and the number of steps to be automated.

Parts can be fed into the manual work steps either statically or dynamically in the form of a second turntable. A second turntable offers further advantages, such as less space requirement. A large number of individual parts can be provided, with what is currently required always ready to hand. This prevents incorrect assembly caused by mixing up components, as the individual parts are provided in the order of the assembly sequence.

If the complexity or quantity of the product to be manufactured is too great for a single workstation solution, several rotary indexing stations can be linked together. Each workstation is equipped according to requirements, either as a manual workstation, a fully automated station or as a hybrid system.

Hybrid assembly system in longitudinal transfer arrangement

As rotary transfer stations are only feasible for relatively small assemblies, the longitudinal transfer arrangement is used for larger products. Here, double-belt conveyor systems in cart or line design are used. This allows products weighing up to approx. 150 kg to be assembled. The most important feature here is the ability to combine manual and automated assembly processes.

Longitudinal transfer systems consist of various modules that can be combined as required. There are modules for manual workstations, automatic stations and intermediate transfer modules. Longitudinal transfer systems can therefore be adapted to almost any task. Transfer modules are available as linear or curved sections, allowing a wide variety of hall situations to be accommodated.

The automatic stations consist of universal base modules, which serve as a platform for process modules. The process modules consist of product-neutral components and individually adaptable superstructures. The automatic stations can be converted very easily and quickly by inserting the process modules into the base modules with a pallet truck and connecting them using plug connectors. A system conversion is usually possible in just a few minutes.

The modular design allows the system to be adapted to the respective order situation. At the start of a product life cycle, for example, the system can initially be set up with 2 manual stations and one automatic station, which requires relatively little investment. As sales increase, the system can be equipped with additional stations and the production process can be gradually automated to a greater extent. When a product reaches the end of its life cycle, the station can be gradually dismantled and the modules that fall off can be used for the successor product.