A fuel cell is a galvanic cell in which a reaction takes place between a fuel and an oxidizing agent . Hydrogen is most commonly used as the fuel and oxygen as the oxidizing agent. The reaction produces three products: thermal energy, electrical energy and water. The principle of the fuel cell was discovered in the first half of the 19th century, and today fuel cells are used in various fields of application. Fuel cells are considered to be particularly relevant with regard to the energy transition - in the areas of industry and transportation, among others.

A brief look back: The history of the fuel cell

The functional principle of the fuel cell was developed back in 1838 by Christian Friedrich Schönbein. The so-called "galvanic gas battery" was quickly seen as an option for the energy supply of the future. However, the fuel cell was forgotten at least as quickly, as less complicated solutions for generating energy - such as the electric generator - enjoyed a larger following.

It took until the middle of the 20th century for the fuel cell to fight its way back from obscurity. At that time, it was primarily the aerospace and military sectors that recognized the specific advantages of the fuel cell as an energy source: The compact design with maximum performance was just perfect for use in situations where space savings and the lowest possible weight were important. This is still one of the many advantages of the fuel cell today.

How does a fuel cell work?

The fuel cell works on the basis of an electrochemical reaction. Unlike a battery, a fuel cell is therefore not an energy storage device, but rather an energy converter - the chemical energy of the fuel is converted directly in the fuel cell. For this to succeed, a specific structure is required.

Structure of the fuel cell

The specific structure of a fuel cell differs depending on the type and intended use. The polymer electrolyte membrane fuel cell, also known as PEM or PEMFC, has been particularly well researched and is widely used in the automotive industry. This type of fuel cell will therefore be examined in more detail below.

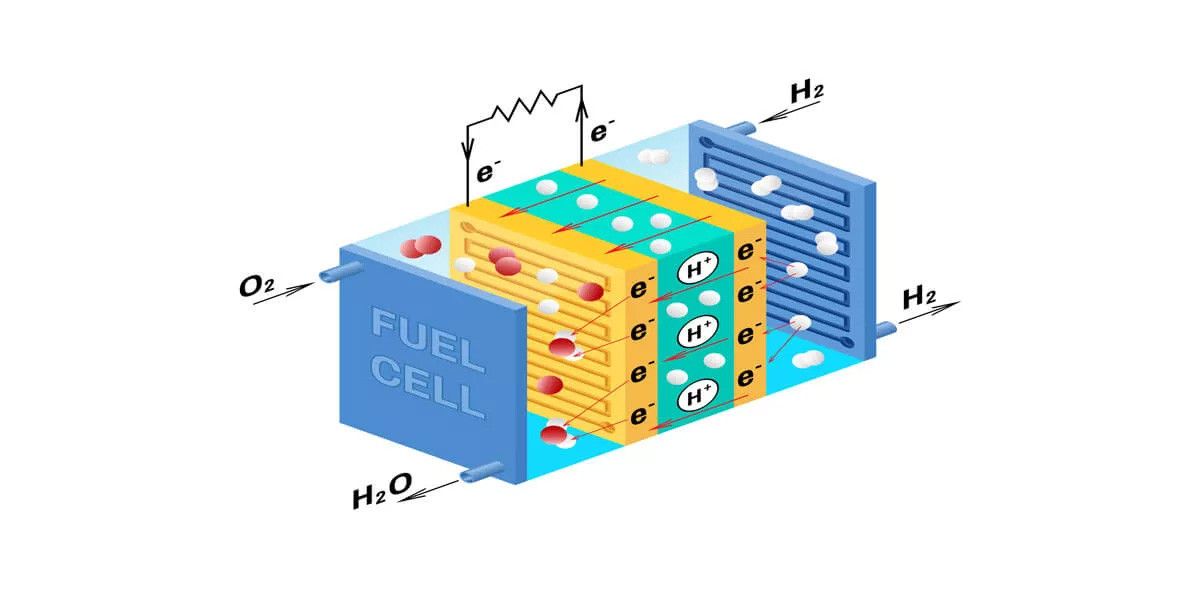

A fuel cell has two electrodes - an anode and a cathode. A polymer membrane acts as the electrolyte between the two. This membrane has two functions: It is responsible for separating the two electrodes and ensuring the selective transport of ions between them.

Function of the fuel cell

The fuel cell is first supplied with hydrogen as fuel and oxygen as an oxidizing agent. It is important to note that the hydrogen is supplied at the anode, while the oxygen is supplied at the cathode. The hydrogen molecules are split at the anode - into positively charged protons and negatively charged electrons. While the protons can pass through the membrane of the fuel cell unhindered and flow to the cathode, the negatively charged electrons are blocked from doing so.

Put simply, the negatively charged electrons have to take a detour to get to the other side, to the cathode. In doing so, they flow over an electrical conductor and can release their electrical energy there. Electricity is generated. Once on the other side of the membrane, the electrons react with the oxygen in the same way as the protons to form water. During this stage of the process, heat is also released as thermal energy.

Important: In the fuel cell, there is no combustion, but rather a conversion of hydrogen and oxygen. This makes the fuel cell very low-maintenance and efficient. At the same time, the electrochemical reaction inside the fuel cell is completely emission-free - which makes it extremely interesting for the energy transition.

What fields of application are there for fuel cells?

The extent to which fuel cells are suitable for certain fields of application or areas of use depends on various factors. Above all, performance and capacity are decisive. However, service life is also an important factor in ensuring that fuel cells can be used profitably.

Self-sufficient systems

Aerospace and the military were the first industries to make increased use of fuel cells. They are used to power self-sufficient systems, such as submarines or spacecraft.

Portable applications

The idea that all mobile devices equipped with a rechargeable battery could also be fitted with a fuel cell for power supply is not new. Numerous companies have already tried their hand at developing small fuel cells for laptops, digital cameras and other mobile devices. However, a truly successful market launch has not yet been achieved. The main reason for the failure to launch fuel cells for mobile applications is the comparatively high cost.

Mobile applications

Fuel cells are used in the energy supply of electric cars, so-called FCEVs (fuel cell electric vehicles) or fuel cell vehicles. They are already relatively widespread, particularly in industrial trucks that are operated indoors. Here, they can be used much more efficiently than battery-powered vehicles because long charging times are avoided. Fuel cell technology has also arrived in individual road transport - although widespread use has not yet been implemented due to a lack of infrastructural and technical prerequisites. In the areas of commercial vehicles, rail transport and shipping, however, its use is already in demand, as fuel cell vehicles without a large battery guarantee a significantly lower weight with a simultaneous range advantage. In addition, the existing H2 filling station network along the main axes can already ensure a sufficient supply for freight transport.

Stationary applications

In the area of stationary applications, fuel cells are mainly used as fuel cell heaters. Depending on their size, models can be used to supply private households as well as companies. The focus here is usually on the use of thermal energy, whereby so-called high-temperature fuel cells are usually used for this purpose. The electrical energy released is often used as an emergency power supply to safeguard against power failures. In principle, however, fuel cells can also be used to ensure a power supply, for example in off-grid areas, or to cover the decentralized power supply in industry. In this context, the combination with an electrolyzer is particularly useful: energy generated via photovoltaics or wind power can be converted into hydrogen, which can then be temporarily stored in gas cylinders or metal hydride storage units, for example, and converted back into usable electrical energy in the fuel cell when required. Such systems are already available as ready-made solutions for detached or semi-detached houses and on an industrial scale. The particular advantage of these systems is that they use renewable energy, which is available virtually endlessly, directly at the point of origin.

Conclusion: Fuel cells as an important factor in the energy transition

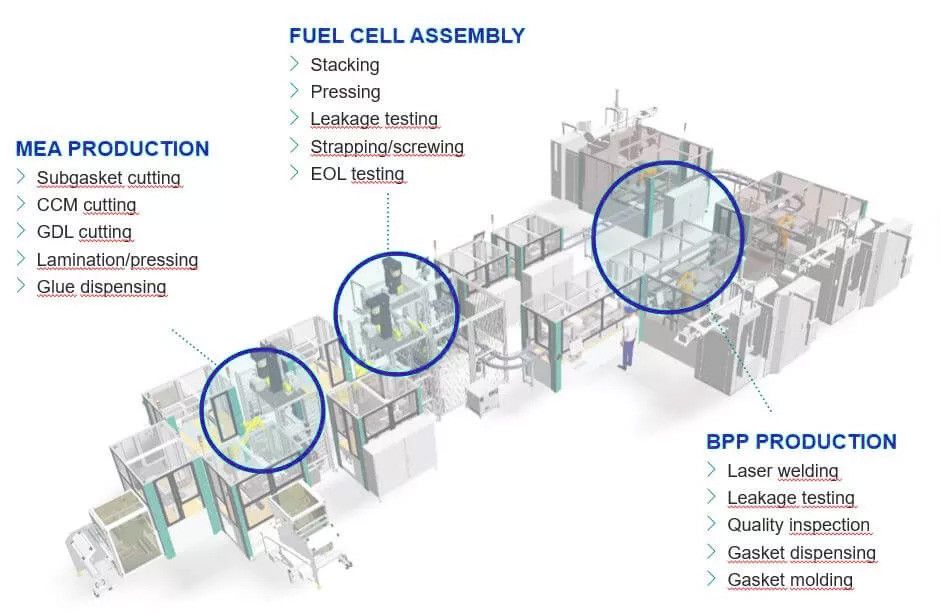

Fuel cells achieve a high level of efficiency with a relatively simple principle and - depending on the origin of the fuel used - are capable of generating green energy. This is mainly due to the fact that they can be used to generate energy with zero emissions. In the future, the expansion of the technology can be expected to reduce the still high costs of fuel cells. Currently available fuel cell generations are generally still manufactured in small series. Production is very expensive due to the high labor costs. As the degree of automation increases and production figures rise, manufacturing costs will fall dramatically, which will also open up a wider range of applications. The basic prerequisite for this step is the incorporation of automation-oriented design specifications. A fuel cell consists of several hundred cells, each of which in turn consists of an MEA (membrane electrode assembly), a BPP (bipolar plate) and a gasket. The "bottleneck" in the current production of fuel cells is not only the time-consuming conditioning process but also the pure stacking process of the cells. New approaches to stacking are needed to meet the growing demand of the future.