What is sheet metal?

Sheet metal is not a material in its own right, but a term for metals that have been shaped. This shape is usually a rectangle, whereby the thickness is much smaller than the width and length.

Sheet steel is most commonly used today, for example in the automotive industry, but many other metals can also be processed into sheet metal, e.g. aluminum, copper, gold or alloys such as brass. The main limitations are the mechanical properties; the processed materials should have a certain toughness and rigidity depending on their use, but must also be ductile. Very stiff and brittle materials cannot be processed into sheet metal.

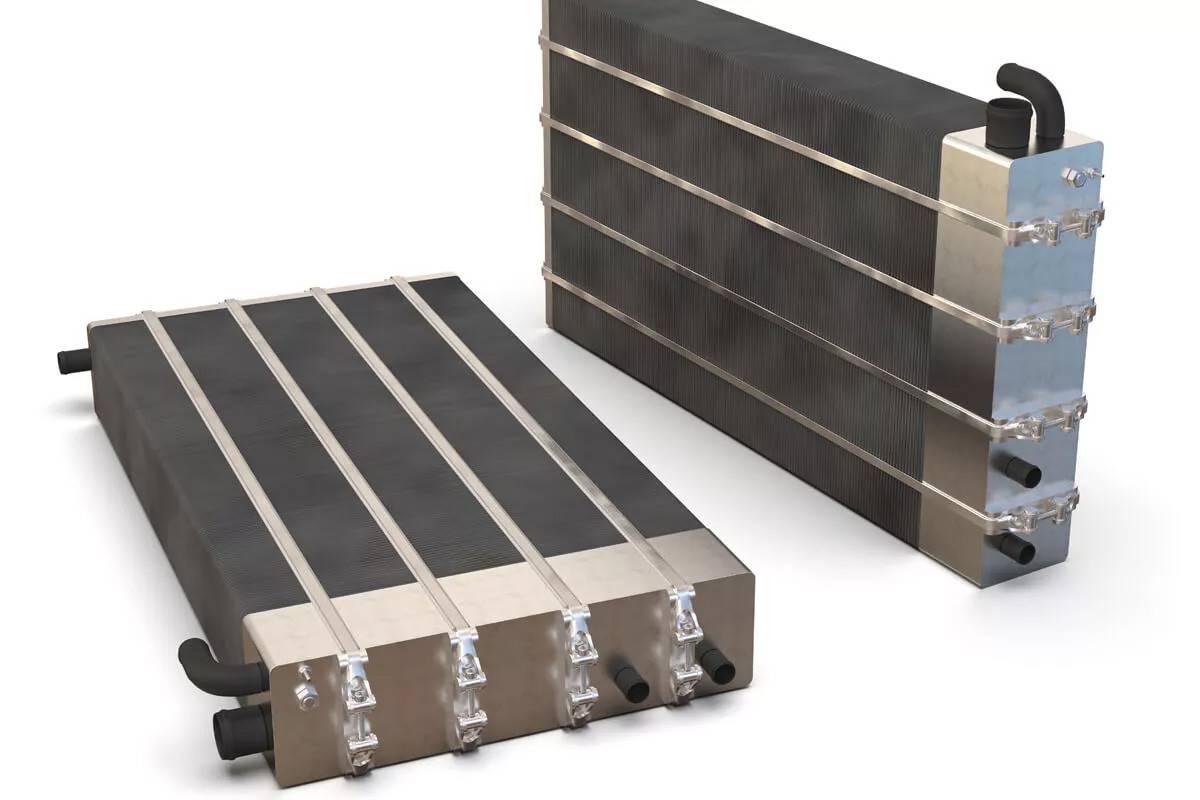

Sheet metal is therefore a semi-finished product that is used as a starting material for a wide range of products, from car hoods to bottle caps.

Sheet metal can be produced over large areas, yet is very thin and light, flat, stable and elastic. They are therefore ideal for any type of cover or cladding. Sheet metal can be formed in many ways. They can be cut, punched, bent or welded. They are therefore also suitable for a wide variety of shapes.

Production of sheet metal

The oldest form of metalworking is forging. In this process, metal is beaten wide with a hammer under the influence of force. This form of metalworking is rarely used today, mainly in the artistic field.

Sheet metal rolling was introduced around 200 years ago and has since developed into one of the most important processes in metalworking. This process is also based on the application of mechanical force. A block of metal is pulled through a gap between two rollers, reducing its thickness by 20-30%. This also influences the crystal structure, which can improve the mechanical properties. A distinction is made between hot and cold rolling in this process. Thick sheets are rolled in a red-hot state. With thin sheets, the heat radiation is so high that the annealing state can only be maintained with a considerable amount of energy, so they are cold rolled. Rolling is not only used in the production of sheet metal; a wide variety of profiles, tubes, wires and rails are also produced using the corresponding rolls.

Cutting and punching sheet metal

A number of processes have been developed for processing sheet metal, allowing a wide variety of shapes to be achieved.

Punching and nibbling are relatively old sheet metal processing methods. In punching, a sheet is cut through by a punching machine or press. This also allows holes in different shapes to be made in the sheet metal. Nibbling machines cut a sheet through a large number of individual holes that overlap. Early punching and nibbling machines had to be controlled manually by the user. This changed with the introduction of coordinate guidance and templates, which made semi-automatic operation possible. Automation was further advanced with the introduction of NC technology and later digital controls. Modern high-tech machines combine punching and nibbling processes and offer a wide range of processing options with high precision. Thanks to their favorable price/performance ratio, they are indispensable in sheet metal processing.

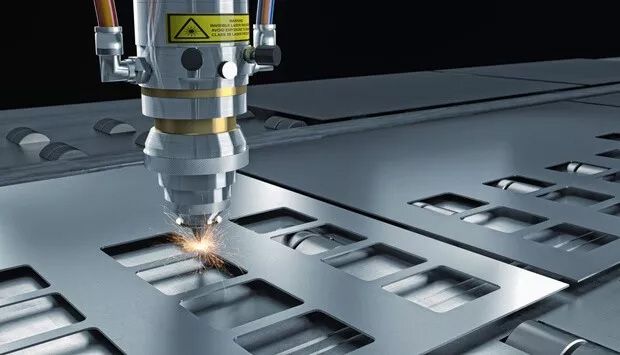

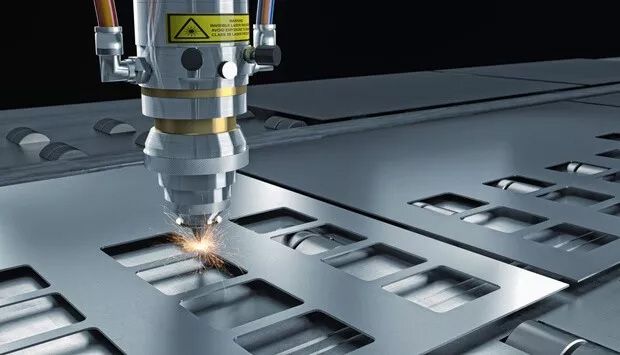

In the 1970s, lasers were introduced to sheet metal processing. It is mainly used for laser cutting and welding. During laser cutting, the material is heated and melted at very high temperatures. The resulting molten material is removed with the aid of a gas stream, creating a gap. Laser cutting is a non-contact and force-free processing technique. Almost any shape can be produced without a single tool change. Cutting is more precise than punching or nibbling at a very high speed and the cut surfaces are particularly smooth. Today, laser cutting is an interesting economic alternative, the cost/performance ratio has increased rapidly in recent years due to various further developments, which is why lasers will probably overtake mechanical processing methods in the future.

In the mid-1980s, a breakthrough was achieved in cutting with the aid of a water jet. Solid particles (abrasive) were added to the water, which meant that hard materials such as stone, glass and even metals could be cut for the first time with a high-pressure water jet. In the meantime, abrasive waterjet cutting has developed into an efficient technology and has found its place in manufacturing technology. The process is particularly interesting because almost all materials can be processed. In contrast to laser cutting, waterjet cutting does not cause any thermal stress, which is particularly interesting for composite materials and plastics. In addition, very thick materials (up to around 1m) can be processed where mechanical processes and lasers would otherwise reach their limits. Waterjet cutting is an alternative to lasers, which is mainly used for processing very thick, highly reflective or particularly thermally conductive metals. It is the most commonly used method for processing plastics.

A comparison of the processes

The punching and nibbling technique is particularly suitable for relatively thin sheet metal parts up to a thickness of around 8 mm. Very hard and brittle materials cannot be processed using this technique.

Materials that can sufficiently absorb the energy of the laser beam are suitable for laser cutting. The laser is particularly important for processing steel, which can be cut through by a laser up to a thickness of around 20 mm without any problems. Reflective materials such as copper or metals with high thermal conductivity such as aluminum can also be cut up to a thickness of a few mm.

Waterjet cutting is primarily used in the border areas of other processes where they become uneconomical or technologically difficult to implement. This is particularly true for highly reflective or thermally conductive metals of high thickness, as well as for plastics and composite materials. It is also an ideal separation process for products where thermal or mechanical stress is prohibited, e.g. in the aerospace industry.

If you have any questions about sheet metal processing, please contactour contract manufacturingdepartment