The primary-secondary analysis is a simple method for assessing the economic efficiency of an assembly system. All handling and joining operations are divided into primary and secondary operations, whereby the lowest possible proportion of secondary operations means high economic efficiency. The methods of primary-secondary analysis are suitable for existing assembly systems as well as those in the planning stage and are used for all types of assembly systems. They help to analyze the economic efficiency of an entire assembly factory, including parts provision, transport, storage, testing and packaging.

Definitions

Primary operations (PV) are all expenditures of energy, time, information and parts to complete a workpiece that add value during assembly. Examples are inserting, gripping or screwing in parts to complete a workpiece.

Secondary operations (SV) are all energy, time and information expenditures required due to the selected assembly principle without adding further value to the workpiece. Examples of this are turning, further transportation, regripping or depositing parts without the workpiece approaching its final state.

The duration of the processes is always used as the measured variable.

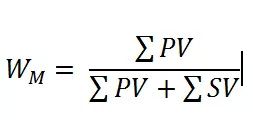

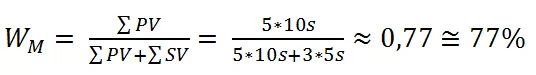

The economic efficiency WM is the sum of the durations of all primary operations in relation to the sum of the durations of all operations:

The efficiency calculated in this way can be used to make statements about the efficiency of an assembly station, an assembly station or an entire assembly system. This applies to all assembly techniques, from purely manual assembly to automatic systems.

An increase in efficiency always means a reduction in secondary costs.

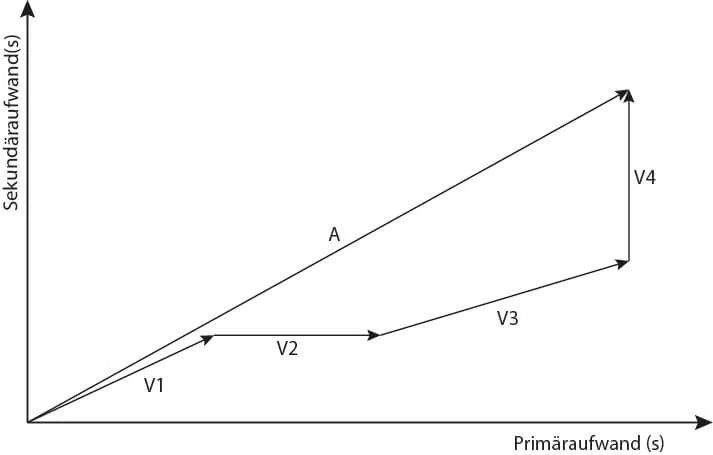

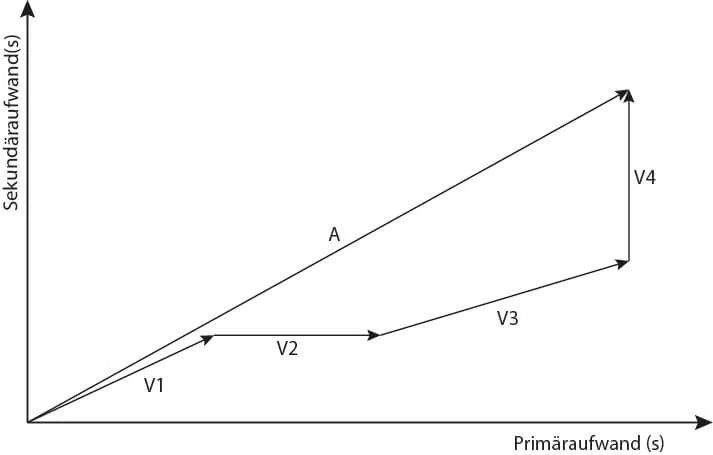

Illustration with the help of effort vectors

A clear interpretation of the primary and secondary effort is provided by the representation as effort vectors. For this purpose, the determined durations of the primary and secondary processes are entered into a coordinate system. The figure shows an example diagram of 4 consecutive individual processes. The total effort vector |A| results from the individual vectors .

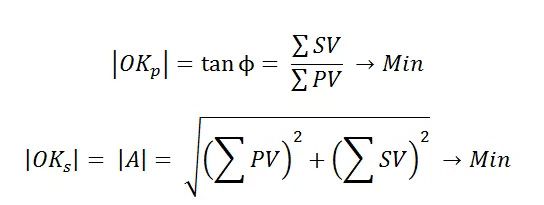

Since a reduction in the secondary effort means greater efficiency, this is considered the primary optimization criterion |OKp| and is equal to minimizing the angle of increase ϕ of the effort vector |A|. A secondary optimization criterion |OKS| is the reduction of the total assembly time or a minimization of the amount of the effort vector |A|.

The following therefore applies:

The distinction between primary and secondary effort depends on the assembly object and the type of assembly. Small appliances and large appliances must be considered separately, and the analysis must also be carried out differently for manual, semi-automatic and fully automatic assembly systems and robot cells. In addition, there are three levels of accuracy for primary-secondary analysis: basic analysis, fine analysis and extended analysis.

Determination of economic efficiency

Basic analysis

The basic analysis is used to determine the economic efficiency of the actual assembly process. It begins with the provision of the material to the assembly station and ends before the product is tested and packed. Intermediate tests that are integrated into the assembly process are also recorded.

Example: manual flow assembly of small appliances

An imaginary product consisting of 5 individual parts is assembled at two manual workstations AP1, AP2. At the first workstation, the basic part T1 is gripped by a worker, brought into a joining position and then connected to parts T2 and T3. The gripping and joining of parts T2 and T3 are each a primary operation, resulting in a total of 3 primary operations on AP1. After the first worker has completed his activities, he places the intermediate product on the intermediate buffer ZP1, which represents a secondary operation. The subsequent gripping and transfer of the pre-assembled components to the second joining device by the second worker is also a secondary operation. Joining the other parts at the second workstation is again a primary operation and depositing the finished product is a secondary operation.

In this example, there are a total of 5 primary operations and 3 secondary operations, the individual times of which are determined in order to determine the economic efficiency. If we assume 10 seconds for each of the joining processes and 5 seconds for each of the gripping and depositing processes, we arrive at an efficiency of :

This simple example makes it easy to recognize that secondary costs can increase significantly if the assembly line contains several stations, especially if bottleneck stations are created to whose cycle the other stations have to adapt.

Detailed analysis

In order to carry out a more detailed analysis, a more precise distinction between primary and secondary operations is necessary. Target values for a differentiation are usually determined using the MTM method. MTM stands for Methods-Time Measurement, in German it is also known as Arbeitsablauf-Zeitanalyse (AAZ). All movement sequences are divided into basic movements to which standard times are assigned.

In the very frequently used MTM-AUS (Universal Analysis System), a distinction is made between the 5 basic movements of reaching, gripping, bringing, joining and releasing. Strictly speaking, only joining is a primary process. Since no joining process is possible without the other basic movements, efforts within the standard times are counted as minimum efforts and primary operations. Times that exceed the minimum effort are counted as secondary operations.

When bringing and reaching, the distance of the part that is easiest to reach is selected as the limit value. If at workstation 1 in the above example, part 1 is 30 cm and the other parts 40 cm away from the joining device, then 10 cm of the distance required for reaching and retrieving parts 2 and 3 count as secondary effort.

Gripping movements count as a primary operation if the worker can pick up the part by hand without additional effort; anything beyond this is secondary effort. Releasing is always a primary operation due to the very small amount of time required.

Extended analysis

A basic analysis of the assembly area and a detailed analysis of the individual workstations are necessary in order to assess the efficiency of an entire assembly. During the extended analysis, further secondary costs may arise, for example due to foremen or additional packaging that does not contribute to added value.

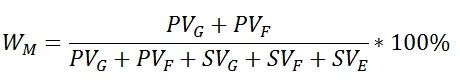

With the primary and secondary costs of the basic and detailed analyses PVG, PVF and SVG, SVF, as well as the secondary costs of the extended analysis SVE, the total efficiency is calculated as follows:

If you have any questions or other concerns, please feel free to contact us!